One of any vehicle’s most crucial components is the brakes. They must be taken care of for decelerating and stopping to be effective and safe because they are in charge of halting the vehicle.

There are numerous other components of the braking system that are crucial, even though many people are aware that rotors and brake pads should be checked frequently.

Today, we’re going to speak about brake lines, a crucial component that keeps your car’s brakes in good operating order. Pushing the brake pedal would be useless without them, after all.

The brake line replacement cost will often range from $150 to $200, but there is more to these numbers than first appears. As this is a crucial component of your car and you cannot drive safely without functional brake lines, you should never put off any brake line replacement or repair.

To say that the brake line in your car is crucial would be an understatement. It’s a vital component of the brake assembly on your car, and it’s what makes the whole system function. We’ll talk about brake line replacement cost, how it functions, and how to change brake lines on your own.

A Brake Line: What Is It?

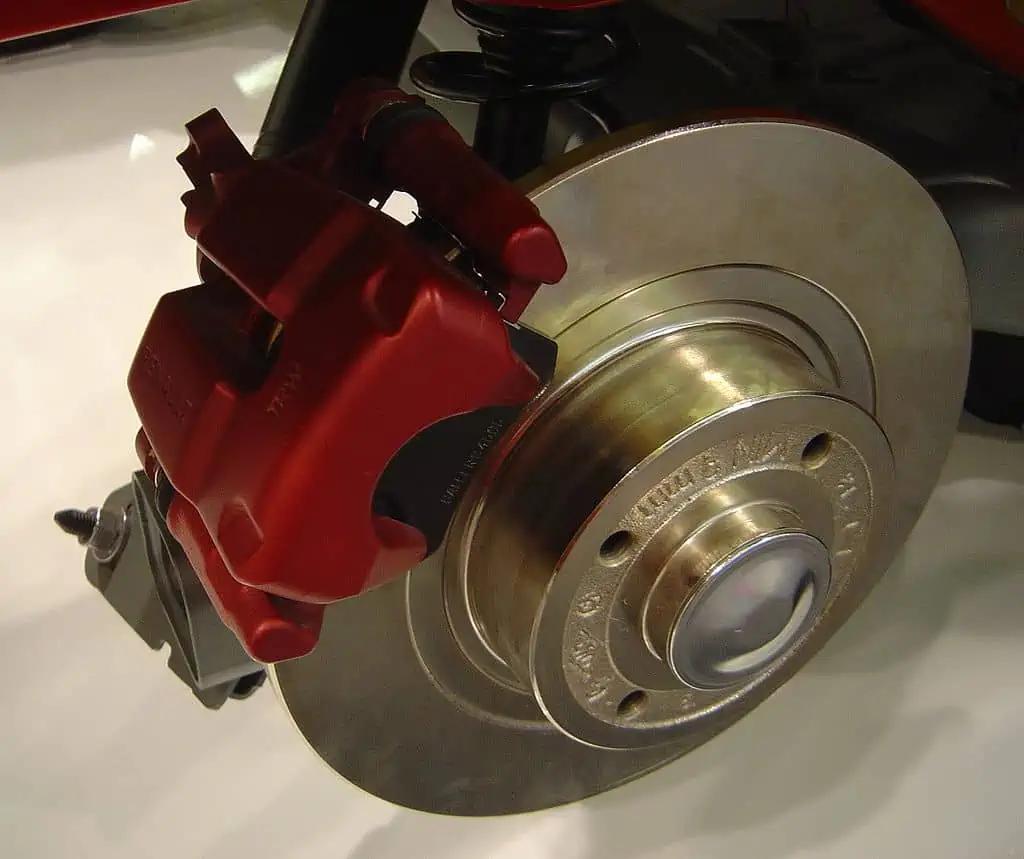

You must comprehend how a car’s brakes operate before we can discuss what a brake line is. The majority of cars on the road today employ a disc braking system, which applies pressure to the disc (also referred to as a rotor) utilizing a caliper and a set of pads.

This causes friction, which slows down your car as result. Drum brakes are still used by some automobiles, although only on the back wheels. Drum brakes operate differently mechanically, but the idea is the same: generate friction to slow the automobile down.

How therefore does the system function? Your car’s master cylinder houses the brake fluid. The system would then deliver these pressurized fluids to your brakes when you applied the brakes. The brake lines, which are required to transmit the fluids into your brakes, enter the picture at this point.

The drum shoe brake lining by Maly LOLek / CC BY-SA 3.0. The brakes are one of a car’s most important parts. Because they are responsible for bringing the vehicle to a stop, they must be taken care of for deceleration and stopping to be efficient and safe.

The brake pads will be forced to migrate inward against the rotor once the fluid gets to the calipers. Your car slows down as a result of the friction that is produced when these brake pads make contact with the rotor.

Brake lines only serve the purpose of distributing brake fluid to your brakes. Your brakes won’t function if the brake lines aren’t functioning properly since the fluid won’t get to them. You will be in danger if this occurs.

What Is the Function of a Brake Line In a Car’s Braking System?

The braking system is typically a hydraulic system that depends on fluid pressure. The way the brakes operate is by using pressure to force brake fluid through the system, which moves pistons in the calipers and brings your brake pads into contact with the rotors.

The car slows down and eventually comes to a stop as a result of this contact between the brake pads and rotors.

Your car’s brake system can move fluid pressure around thanks to the brake pedal. Your car decelerates more quickly the harder you press the pedal, correct?

To transport the fluid from the reservoir and provide the pressure required to push the piston, the brake fluid is moved through brake lines. Bracket lines are crucial because they transport all braking fluid.

Both solid materials, such as steel tubing, and flexible materials, such as hoses, can be used to create brake lines. Brake lines, regardless of their construction, are vulnerable to wear and tear just like any other component of your car.

The distinction is that because damaged brake lines are an integral part of the system that keeps driving safe, they are frequently regarded as emergency repairs. Your car is unsafe to drive if the brake lines are broken because braking failure is more likely to occur.

What are the Main Causes of a Bad Brake Line?

Like most parts of a car, brake lines will eventually deteriorate. A lot of the time, wear develops from the inside out.

The metal inside brake lines can rust and corrode from the inside as a result of the water that brake fluid retains over time. This may eventually result in a hole forming on the brake line’s exterior, enabling brake fluid to leak and reducing brake pressure.

Rubber hoses may also experience the same problem. The heat and moisture inside rubber hoses degrade and break down the rubber. Often, the first indication of a problem is visible bulges or cracks.

Brake lines can potentially stop working entirely. Corrosion from the inside or damage from the environment on the outside might cause this. This breaking may be brought on by salt and road debris.

Finally, if brake lines collapse, they may malfunction. This lowers the fluid pressure in that specific line, which can diminish the effectiveness of your brakes. When you try to stop, the car will pull to one side as a result of this.

An automotive disk brake by David.Monniaux / CC BY-SA 3.0. Although many people are aware that brake pads and rotors should be maintained periodically, there are many other important parts of the braking system.

Which are the Common Symptoms of a Bad Brake Line?

Poor brake functioning is the only indication that your brake line is failing or has failed because it is an essential component of your braking system. You might notice that your brakes aren’t working as well as they should if your brake line isn’t operating properly.

For instance, even after applying quite a bit of pressure to the brakes, the vehicle still doesn’t stop as quickly as it should. The worst-case scenario is when the car completely loses braking—that is when the brakes are never applied.

Brake pads that are worn out may potentially be to blame for your car’s braking issues. Your car’s braking performance may also be impacted by trapped air in the brake lines, in which case you will need to bleed the system.

Whatever the case, if you have braking problems, we strongly advise that you fix them. Driving while your brakes are damaged is extremely risky and could land you in a catastrophic accident.

There are no other obvious symptoms of a damaged brake line aside from this. Having said that, you can examine your brake lines for outward indications of wear or damage. By the hose fittings, look for leaks, tears, cracks, and rust.

These might have an impact on how well your automobile brakes. Even though the symptoms listed below aren’t specifically related to brake line problems, keep an eye out for them because they could point to a problem with the braking system:

1. The Brake Warning Light Comes On

If your parking brake is released and you notice a brake light on your dashboard, you should examine your vehicle’s braking system.

This is your car’s direct way of informing you that something is wrong with the brake system and that it needs to be fixed, much like the check engine light.

Low brake fluid levels and issues with the ABS unit are some of the causes of this. It is best to bring it in for evaluation and repairs.

2. Grinding Noises While Braking

You should inspect your brakes right away if your automobile makes a grinding noise when you brake. Numerous factors, such as corroded brake pads and other items lodged in the caliper, might contribute to this. Whatever the case may be, you shouldn’t overlook this critical problem.

3. The Car Drifts to One Side When Braked

When you brake, if your automobile pulls to one side, just one of the brakes is working properly. A faulty brake caliper or a brake line issue may be to blame for this. In any event, it would be prudent to get it checked out and fixed right away.

4. Leaks In Brake Fluid

A brake fluid leak typically indicates either worn brake pads or a hydraulic issue. Sometimes it can be challenging to locate a brake fluid leak. Check your fluid levels to make sure they are at the right level if you think you may have a brake fluid leak.

To check if the fluids are at the proper level, simply find the brake master cylinder and reservoir on your car. To find out the recommended amount of brake fluid your automobile should have, consult your owner’s handbook.

A disc brake bleeding screw by Ibjoe. After filling off the brake fluid to the appropriate level, bleed the brakes to let any trapped air out. You must first remove the bleeder cap, which is found on the brake caliper or wheel cylinder, to accomplish this, and then have another person apply the brakes to expel the air out of the bleeder cap.

5. Unstable and Spongy Brake Pedal

Your brake pedal will likely feel strange if there is an issue with your car’s braking system. If the brake pedal is spongy or wobbly, you won’t encounter much resistance when pressing it.

You should check this if you press the brake pedal and nothing happens but the pedal dips to the ground. Usually, the problem is with the brake fluid, and there may be a lot of air trapped in the system.

Which are the Different Kinds of Brake Lines?

If car aficionados seek better braking performance, they frequently update their brake pads and calipers. But it turns out that there are several brake line types you can employ, and they can have an impact on how effectively your automobile brakes.

You can purchase a variety of brake lines for your car, including the following types:

1. The Rubber Brake Lines

The most typical material for brake lines is rubber, and chances are that’s what your car has. They are strong and tough, and they can function without replacement for roughly six years. Under heavy use, they do have a propensity to flex and swell, which is not ideal.

Braking will be affected if a brake line swells or flexes because the fluid pressure will be reduced. The brakes are engaged by the braking mechanism using fluid pressure. The brake pads won’t apply as well as they should if the pressure isn’t strong enough, which will reduce braking effectiveness.

Rubber brake lines may rupture if they come into touch with sharp rocks or twigs that get beneath your automobile, in addition to the swelling issue. This will result in a leak and a drop in the system’s fluid pressure.

2. The Steel Brake Lines

Steel brake lines have a few benefits, the first of which is that they are impervious to punctures.

You won’t need to be concerned that your brake lines will rupture if they come into touch with jagged rocks or twigs because steel is much stronger. Steel brake lines are preferred by off-roaders in part because of their increased durability.

Steel brake lines have a second advantage over rubber brake lines in that they won’t bloat. This guarantees that the fluid pressure will be at its ideal level even when the steel lines are put to a lot of use.

Steel lines are more dependable in an emergency and should provide constant braking performance. They also provide a harder feel and better reaction when pressing the pedal. Steel lines are frequently found in performance automobiles.

There are several limitations with steel brake lines, though. For starters, they are still susceptible to breaking over time and may corrode with time.

Second, because they are less flexible, they are more susceptible to stress, which could damage relationships. To make sure they are still attached correctly, it is advised that they be examined more frequently.

An automotive brake pad by Treemonster86 / CC BY-SA 3.0. Typically, a brake fluid leak points to either worn brake pads or a hydraulic problem. It can occasionally be difficult to find a brake fluid leak. If you suspect a brake fluid leak, check your fluid levels to make sure they are at the proper level.

3. The Braided Brake Lines

The soft brake line tube, which is frequently constructed of rubber, is typically enclosed in a mesh formed from braided steel strips.

This brake line protection is provided by braided steel to give the brake lines an additional layer of defense against tearing and punctures that would otherwise be likely to occur with rubber brake lines. They also aid in limiting tube edema.

Braided brake lines are not only slightly more flexible than hard steel lines, but they are also more resilient than rubber. Less strain is placed on the connections as a result. The soft tubing is covered in braided steel, so you won’t be able to physically check the lines for leaks and corrosion.

This means braided lines will require routine maintenance to ensure they’re constantly in peak condition and you might not detect the issue until it’s too late.

This kind of brake line is frequently used in race cars and competitive off-road vehicles. The braided brake lines for race cars pose little problems because they are routinely repaired in between races.

Braided steel brake lines have also been the subject of internet debates where it has been asserted that they are abrasive, eat through, and harm other parts they constantly come into touch with.

If you’re considering converting to braided lines, have this in mind even though we can’t seem to verify it.

4. The Performance Brake Lines

We refer to brake lines made of other robust materials, such as braided carbon fiber, kevlar, and even Teflon, as performance brake lines. They aren’t inexpensive, as you might expect, and will have a significant impact on your brake line replacement cost.

However, they are worth the money because they are less likely to expand with heavy use and can withstand greater stress. This increases their dependability and improves braking effectiveness.

Many auto enthusiasts upgrade the brake calipers and brake pads when customizing a vehicle to improve stopping power.

However, replacing the brake line can also aid in better braking performance and increase the dependability of your overall braking system under demanding conditions. Although the connections are not under as much stress, these performance lines are typically comparable in strength to steel and braided steel lines.

5. The Brake Line Upgrade

Now, if you’re on a tight budget and the brake line replacement cost is too costly for you. However, there are several situations in which you should upgrade the brake lines. First, it would be advisable to upgrade your brakes system generally if you adjusted the engine and created performance improvements.

More performance equals greater speed, and greater speed calls for greater braking capability. It’s a good idea to change the brake calipers and pads, but you should also switch to a performance brake line for greater braking performance.

The brake master cylinder by Specious / CC BY-SA 4.0. The braking fluid is kept in the master cylinder of your car. When you applied the brakes, the mechanism would then send these pressurized fluids to your brakes. Here is where the brake lines, which are necessary to carry the fluids into your brakes, come into play.

Additionally, if you frequently drive your car on the racetrack, superior brake lines mean a reduced chance of swelling from repeated severe use. This will make your braking system more dependable and long-lasting.

A steel or braid brake line is an excellent option if you frequently go off-roading, as is upgrading your brake line. Steel lines are much less prone to puncture, as we’ve already stated. As a result, you can drive off-road without worrying about rocks or twigs breaking your brake lines.

There is no need to update your brake lines if all you want to do is replace the brake line and you don’t do either of the things we discussed above. You can view an illustrative YouTube video to better understand the differences between steel brake lines and conventional rubber brake lines.

How Much Does the Brake Line Replacement Cost?

The price to replace your brake lines depends on the brand and model of your car. Most autos typically cost between $30 and $60 for parts. However, adding labor will increase your brake line replacement cost to between $150 and $200.

It’s also crucial to remember that this is the price you pay when you bring your automobile to a non-affiliated repair facility. The price might be as much as $400 if you take your automobile to the shop.

The part is rather inexpensive compared to most autos, which is fantastic news. The cost of a brake line unit is under $80, even for high-end vehicles like the Mercedes-Benz G550. You will notice a pricing difference when purchasing steel and performance lines.

For instance, a set of steel brake lines might run as much as $120. Carbon fiber lines, however, can cost up to $300 for a set. However, if you’re using OEM components, the price actually shouldn’t exceed $60.

Brake Line Replacement Procedure

You can lower your brake line replacement cost by replacing a brake line yourself with the proper tools since it is a somewhat challenging task.

We advise against performing it yourself, though, unless you’re confident in your mechanical knowledge, as this is a crucial part of your braking system.

Depending on your brake line assembly, there are two ways to change it if you’re confident you want to do it yourself:

The ABS and brake dashboard warning lights by Ahanix1989. Similar to the check engine light, this is your car’s direct way of telling you that there is a problem with the brake system and that it needs to be serviced.

Method 1 for Brake Line Replacement: Flexible Brake Hoses Replacement

- To make it simpler to access the brake component, remove your wheel.

- The brake system’s hose or pipe should be disconnected. Remove the retention clip connecting the steel line and the hose to accomplish this. After that, use a wrench to turn the connector until it releases.

- Avoid over-cranking these connections to avoid bending the metal brake lines. If so, you will also need to replace them.

- All fasteners and brackets along the flexible line should be removed. Between the central line and the wheel, the brake line may be attached to the strut or other stable places. These mounting connections will need to be loosened and removed.

- Remove the connection to the brake after the line has been cut off from the master cylinder. At the brake line’s termination, loosen the bolt. To do this, you typically require a 14mm socket or wrench, though the size can differ across cars. Typically, a washer will also need to be taken out.

- Replace the brake caliper with the new lines after removing the old ones.

- Reinstall the retention clip before connecting the brake lines to the master cylinder. Reconnect any brackets or mountings that hold the brake line, if necessary.

- Bleed the brakes to release any trapped air after topping off the brake fluid to the proper level. To achieve this, you must first remove the bleeder cap, which is located on the brake caliper or wheel cylinder, and then have someone else apply the brakes to force the air out of the bleeder cap. When you notice liquid dripping from the bleeder cap, the procedure is complete, and you can close the cap. Beginning with the caliper closest to the reservoir, repeat this for each one.

Method 2 for Brake Line Replacement: Mounted Brake Line Replacement

The technique for replacing mounted brake lines is a little different. The steps you should take are as follows:

- To better have access to the brake line, remove the wheels.

- Disconnect from all of the distribution blocks’ connections. To start, you should cut the line at the distribution block with a pair of side cutters. You will then find it simpler to attach a socket to the fitting and take it out of the distribution block.

- The brake lines should be disconnected from the master cylinder. Avoid twisting the cables or removing the connections.

- Remove any mounting clips that the brake lines may have.

- Take off the lines from the car’s foundation. When all of the connections are undone, you should only do this so you may remove the brake lines from underneath the automobile.

- Put the new brake lines into the master cylinder’s proper fittings. The additional lines can then be used to pass underneath the vehicle.

- The distribution blocks should be connected to the new lines.

- Brake fluid should be added to the system, followed by a system bleed.

- We advise against performing brake line replacement on your own. Because of the process’ complexity, other components could be harmed if you don’t know what you’re doing. In this situation, you will also need to replace them and hire a professional to complete more expensive repairs.

An electronic parking brake (EPB) by Kārlis Dambrāns / CC BY 2.0. You should check your car’s braking system if your parking brake is released and you see a brake light on the dashboard.

What Is the Life Span of a Brake Line?

Brake lines typically require little to no maintenance and last for roughly six years. However, if you frequently take your car off-roading or to a track day, we advise checking it more frequently.

Watch out for swelling, corrosion, and other deterioration indicators. In general, checking your brake lines every two years is a smart idea. Unless you frequently drive on tracks or off-road, most brake lines, especially rubber and performance ones, don’t need much maintenance.

Otherwise, it’s good to examine them every two years. Remember to check the amount of your brake fluid every two years as well.

Is It Safe to Drive a Car with a Bad Brake Line?

Even though replacing brake lines costs less than many other auto repairs, you can decide against making the repairs. Perhaps your finances are extremely tight or you are unable to get your automobile repaired.

Driving without replacing your brake lines is not safe, though. For your protection and the safety of others around you on the road, you must have complete control of your car’s brakes. A brake line that has been damaged poses a major safety concern, thus you should never drive one.

You have two options: either take care of the brake line repair or refrain from driving your automobile, regardless of the reason you are reluctant to finish repairs on your car.

Is It Possible to Avoid Incurring the Brake Line Replacement Cost?

Preventative maintenance is the greatest approach to avoid the cost of replacing rusty brake lines or replacing replacement brake lines, just like with any other auto repair.

To find out how regularly you should get your brakes inspected by a mechanic, consult your owner’s manual. If your handbook is silent on the subject, at the very least have them checked every 30,000 miles and at 100,000 miles.

The Conclusion

In conclusion, pressurized fluids are used by your braking system to activate the brake pads. The brake line is used to transport these fluids from your master cylinder to the brake calipers.

Your braking system won’t be able to transfer the fluids at the proper pressure if your brake line swells or punctures, which will result in a loss of pressure. Your brake pads won’t properly engage as a result, and your automobile won’t be able to brake effectively. You run the risk of accidents if your vehicle lacks brake capability.

The importance of your car’s brake lines to the braking system cannot be overstated. To keep your car’s braking system in good shape, you should replace any damaged brake lines right away.

If you have a problem, keep an eye out for warning signs of brake problems. Some of the most typical indications that you might have a brake line problem include spongy brake pedals and a decline in brake performance.

We advise that you hire a professional to replace your brake lines because they might be somewhat challenging to do so. When you consider how crucial it is, the brake line replacement cost is relatively inexpensive and economical when compared to other repairs.

The ABS and brake dashboard warning lights by Ahanix1989

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”