A motor vehicle’s steering system is made up of three interrelated basic parts that cooperate to provide smooth steering. These are the intermediate steering shaft, steering gearbox, and steering wheel.

We’ll go into great detail about the latter in this essay. The majority of these will relate to problems with the intermediate steering shaft in your vehicle.

The shaft serves as the system’s main structural element. It functions as the link between the steering wheel and the steering gearbox, or in lightweight vehicles, the rack, and pinion.

Where the driver-side hub and the drive shaft are joined, the shaft consists of a thin, metallic construction in the shape of a cylinder that is held in place by four needle bearings. As the primary instrument for vehicle movement and control, it is a crucial component.

But how can you tell when a component isn’t performing at its best? What are the warning indicators you need to watch out for? It is susceptible to mechanical failure just like any other mechanical part of a vehicle.

The lives of other drivers may be at risk because of this, and the shaft is not an exception. Continue reading this post as we will explain these symptoms and offer advice on how to identify them before they become a larger disaster.

An Intermediate Steering Shaft Overview?

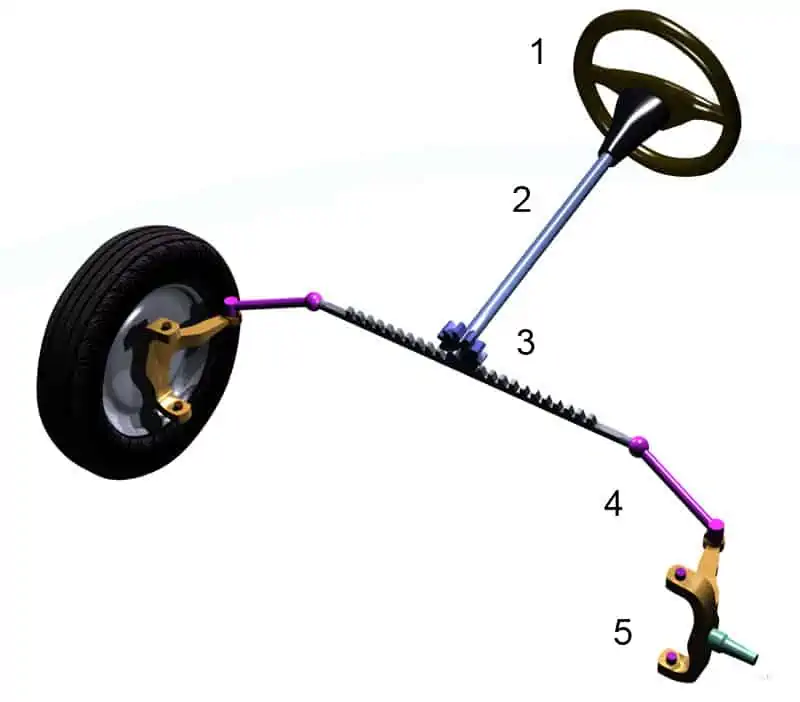

At either end of the intermediate steering shaft are two “universal joints.” In the language of vehicle technology, these joints are also known as the U-Joint coupling.

In vehicles with a rack and pinion steering system, they hold the rotary valve and the steering wheel together to sustain the angle between the shaft and the gear.

The steering wheel is connected to one U-Joint, while the steering gearbox is connected to the other. This makes the wheel’s turning and transition easier.

Rack steering in an automobile by LaurensvanLieshout / CC BY-SA 3.0. Steering system: 1 Steering wheel; 2 Steering columns; 3 Pinion; 4 Steering arms; 5 Steering knuckles. To maintain the angle between the shaft and the gear in cars with rack and pinion steering, they keep the rotary valve and the steering wheel together.

The shaft rotates as the steering wheel is turned. The procedure engages the gearbox, allowing the wheel to be turned without exertion.

To allow the steering tilt and telescope feature, as well as for crash safety, the steering shaft turns at an angle.

The U-Joints must be able to assist the intermediate steering shaft smoothly and without undue effort or resistance transferring the steering force from the steering wheel to the steering rack at an angle.

An Intermediate Shaft: What Is It?

The shaft is typically found under the dashboard, in a spot that could be challenging to find. This might make it very challenging to spot any shaft-related problems early on.

The driver, passengers, other drivers, and the general public may all be at risk if this critical component exhibits even a small problem.

The steering wheel is a primary source of a car’s power. One aspect that draws people to a car brand is this one. One quality in which a car company may take pride is simple steering.

Every driver hopes for certain characteristics while making turns while driving, including comfortable, dependable, precise, and sporty handling.

Early detection of mechanical issues with the steering system is always crucial to preventing more serious issues from developing. A bad intermediate steering shaft might make the steering wheel seem slack or seized up.

Driving a car with a defective shaft mechanism in the steering system is extremely risky, hence such a car shouldn’t be maintained on the road.

When a problem is discovered, a mechanic should be consulted as soon as possible to assist in the diagnosis of the problem.

Where Is the Intermediate Steering Shaft Located In a Car?

Under the dashboard, in the center of the car, is where you’ll find the intermediate steering shaft. The steering wheel is connected to the rack and pinion system via a metal shaft.

The intermediate steering shaft is normally coated with a corrosion-resistant substance to prevent rust, and it is composed of high-strength steel for longevity.

A crucial component of the steering system, the intermediate steering shaft must be kept in excellent shape to ensure appropriate operation.

How Does the Intermediate Steering Shaft Work?

The rod that joins the steering wheel to the rest of the steering system is known as the intermediate steering shaft. A universal joint connects the intermediate steering shaft to the steering wheel, and another universal joint connects it to the steering gear.

A crucial component of the steering system, the intermediate steering shaft is in charge of transmitting the turning force from the steering wheel to the steering gear.

The universal joints compensate for misalignment between the steering wheel and the steering gear while allowing the intermediate steering shaft to transfer the turning force.

The steering shaft is mounted on the sports car chassis by Leonard G / CC SA 1.0. There are two “universal joints” at either end of the intermediate steering shaft. These joints are also referred to as the U-Joint coupling in the language of automotive technology.

What are the Common Symptoms of a Bad Intermediate Steering Shaft?

Have you ever questioned why the steering shaft in your vehicle isn’t performing to its full potential? How do you see the earlier signs of a faulty steering shaft?

This article delves into all the warning signs and symptoms of a poor shaft and offers advice on how to deal with them, as was already promised. Every part of a vehicle has distinct symptoms that may be traced back to its cause. There are several examples of poor steering shafts.

Any attentive vehicle owner will notice and experience several adjustments in the control and navigation that might make the job more challenging and unpleasant.

There is a mechanical issue that has to be addressed right away and shouldn’t be disregarded when a procedure that should be simple and pleasurable starts turning into a laborious chore.

The problems might manifest in a variety of ways, but the following are some of the most typical signs of a broken shaft.

1. The Steering System Is Making an Unpleasant Sound

It might be challenging to hear a strange or unpleasant-sounding vehicle on the road. However, since every vehicle owner is very familiar with how their vehicle would sound both at peak performance and when there is a malfunction someplace, these shouldn’t be a major concern.

The bond between a driver and his or her vehicle is comparable to that between a mother and her kid.

You should be able to tell that something is wrong if the steering system starts making a funny noise. The unpleasant noise that the intermediate steering shaft frequently makes is similar to a clutch noise or a popping sound.

Typically, it starts as a minor, harmless noise, but if ignored, it grows and intensifies until it becomes a significant issue. The steering wheel eventually stiffens and becomes exceedingly challenging to turn or operate. What is the primary reason behind this?

As we already mentioned, the shaft has needle bearings that help the wheel travel smoothly and with minimal effort. To combat rust and corrosion, the bearings require regular lubrication. These enhance its functioning, which was created at its best.

The grease could, however, start to dry out with time. The system starts to corrode and experience corrosion. Due to wear and tear the system’s efficiency declines. Driving restrictions start to appear.

Any attempt to turn causes noise as the steering mechanism becomes more rigid. The system is broken beyond repair, and if it is used continuously without a solution, the drivers’ and other road users’ lives are in danger.

A whole system replacement will be suggested by a qualified service mechanic. The greatest course of action to assist prevent future troubles with steering wheel complications may appear excessive and expensive.

2. The Steering Wheel Is Hard to Turn

A vehicle always moves because of the steering wheel’s ability to freely spin when the driver is at the wheel. Every vehicle driver always takes delight in having a smooth steering wheel. The thrill of driving with a smooth steering wheel is constantly navigating the twists with ease.

Non-assisted steering box of a motor vehicle by A7N8X / CC BY-SA 3.0. Failures of the steering shaft are often caused by wear and tear. Over time, the parts degrade. As a result, their performance potential would be reduced, necessitating their replacement.

For simple driving, a smooth transition and effortless rotation power are essential. There is a problem with the steering system when it is difficult to move the steering wheel and driving seems more like a strenuous workout than effortless navigation. The main culprit is almost often the steering shaft.

If you encounter this while driving, you must stop right away and search for a towing company to assist in getting your vehicle to a facility where the steering shaft may be inspected. If you don’t have any experience in this, avoid performing the servicing yourself.

If you are a mechanical engineer or have some expertise in this line of work, you can only analyze the universal joint issue in the wheel as the principal source of this threat.

Additionally, without prior knowledge, it is very hard to access the steering system and rectify this. You must hire a professional to do it for you to spare yourself the hassle of trial and error.

3. A Loose Tilt In the Steering Wheel

The automotive sector has not been left behind as new technology developments appear regularly. Modern vehicles are always developing more cutting-edge technical features for navigation and comfortable journeys.

To improve comfort and aesthetic delight, certain contemporary vehicle models include steering wheels that can be tilted to the driver’s preferred inclination.

Just as an extra benefit to make driving more pleasant, a tilting steering wheel is available. The performance and operation of the car are not altered or visibly improved. It’s important to lock the steering wheel into place once you’ve adjusted it to the proper angle.

The intermediate steering shaft is the main offender, though, when lock-in becomes difficult and the steering wheel consistently comes free even after locking in and fails to maintain its lock-in angle.

There is a problem with the connection between the steering wheel and the steering gearbox whenever this control problem manifests itself.

A loose steering wheel will inevitably cause you to lose control of the vehicle. To diagnose the problem with the car’s steering shaft, consult with an automotive professional.

Here, the mechanic would put your vehicle through a dry-park test. The technician examines each steering linkage socket as the helper moves the steering wheel slightly from side to side while the mechanic is seated on the tires.

They may occasionally even elevate the vehicle off the ground for a better view to aid with the diagnosis.

4. No Return to the Central Position for the Steering Wheel

The steering wheel should always return to its initial lock center position while the vehicle is stationary or when traveling straight ahead, with the car brand symbol in the exact middle.

When you turn the steering wheel, but it won’t return to its center lock position once you remove your hands from the wheel, there is a flaw in the steering system that has to be fixed right away. For all power steering systems, the spring back to the central lock position is a crucial safety element.

Mechanical rear steering box by Soyuz72 / CC BY-SA 4.0. A seamless transition and frictionless rotation force are crucial for straightforward driving. When turning the wheel is challenging and driving feels more like a taxing workout than simple navigation, there is an issue with the steering mechanism.

If ignored, this is typically a formula for disaster. Driving becomes difficult, and maneuvering around bends and twists gets tiresome. The vehicle turns into a moving death trap.

The lives of the driver, the passengers, other drivers, and even members of the general public are in danger. Typically, the connecting steering shaft is where the problem originated.

Here, the mechanic performs a “flick test” as soon as you bring the vehicle into a mechanical service bay. In a Road Performance Assessment, the wheel is “flicked” to the right while the vehicle is being driven down the road to see if the direction of travel remains to the right.

If it does, it is obvious that frequent lane correction is necessary and that an issue exists that has to be addressed.

5. The Needle Bearing Is Corroded

As was already mentioned, the intermediate steering shaft’s compartment has four significant needle bearings that aid in the smooth rotations of the shaft. In this configuration, oil is added to the bearings to assist reduce friction and glide and stop corrosion from accumulating.

The grease is also intended to lengthen the lifespan of the bearing needles so that regular maintenance is not necessary. After that, the whole bearing compartment is sealed to stop moisture from entering and causing corrosion.

However, there is a good chance that the grease within the bearing dries up after the vehicle has been driven for a long time or when the seal protecting this component has cracked.

When the barrier’s seal is compromised, moisture gradually seeps into the system and corrosion takes place. Premature wear and tear is the outcome of this.

Because it is situated inside the engine compartment, the lower steering shaft U-Joint is frequently linked to this issue. Three main issues might result in a steering shaft U-Joint failing.

- The steering may become stiffer at specific angles if the U-Joint is seized.

- While rotating the steering wheel, there can be a popping or clunking sound.

- Driving requires the driver to adjust the steering when it seems sloppy to keep the car going straight.

If these problems are ignored and no immediate action is taken to correct them as they emerge, the intermediate steering shaft might sustain destruction. Through manual lubrication, the effect of corrosion can be reduced. But for how long will there be manual lubrication and ongoing management?

Why Does the Intermediate Steering Shaft Fail?

Wear and tear is the primary cause of shaft failures. The components deteriorate with time. They would need to be replaced because this lowers their performance potential. However, there are still more aspects, which we discuss below.

1. Damaged Seal Protecting the Grease and Needle Bearing

One of the main reasons the steering shaft fails is due to this. The grease in the needle bearing is protected by a seal. The grease dries up when a seal is damaged. The drying of the oil causes more friction and noise, as well as stiff steering.

Electric Power Assisted Steering (EPAS) power steering column by Samf4u / CC BY-SA 4.0. There is a problem with the steering column that has to be rectified right away whenever you spin the steering wheel but it doesn’t immediately return to its center lock position once you take your hands off the wheel.

In addition to allowing moisture and dust to enter the bearing, seal failure also promotes corrosion and rusting. The bearings can’t operate at their best. As a result of the severe corrosion, the shaft may shatter. When the steering shaft is damaged, the aforementioned issues appear.

2. Damage to Physical Systems Due to Prior Accidents

Another reason for shaft failure might be physical harm. If you were in an accident that could have bent the shaft or damaged the universal joints but went unreported, it may eventually lead to failure. After significant incidents, a thorough service inspection is usually required to replace any loose, damaged, or deformed parts.

3. Factory Defects In the Motor Vehicles

Vehicles occasionally have manufacturing flaws. As a result, the majority of auto manufacturing firms have a vehicle recall to assist provide after-sale services for any technical issues that can arise during manufacture. Metal components that are not manufactured correctly become brittle and are susceptible to breaking.

The metal may not be as strong as anticipated if the alloy it was manufactured from was improperly created. There could also be a few tiny cracks that resulted from the manufacturing process. These fractures may enlarge over time and finally lead to the shaft failing or breaking.

4. Careless Habits When Driving

The primary factor in intermediate steering shaft failure is poor driving practices. Your car may experience many issues when an intermediate steering shaft fails. Some of the most typical negligent driving behaviors that might cause an Intermediate Steering Shaft failure are listed below:

- Failing to use the correct turning radius: When making a turn, you should always employ the correct turning radius. Cutting corners or making abrupt bends places undue strain on the intermediate steering shaft. This strain may eventually lead to the shaft failing.

- Hitting potholes or curbs: The intermediate steering shaft might be damaged by running into a curb or pothole. The shaft may collapse if the damage is serious enough.

- Going fast over a bump: When you encounter a bump in the road, you should reduce your speed to prevent harm to the intermediate steering shaft. Speeding over bumps creates excessive strain on the shaft, which might cause failure.

- Driving on unpaved roads: The intermediate steering shaft might become damaged on rough roads. If you must go on a bumpy road, make cautious to drive slowly to prevent shaft damage.

The primary factor in intermediate steering shaft failure is poor driving practices. Be careful to steer clear of the negligent driving behaviors outlined above if you wish to prevent an Intermediate Steering Shaft failure.

What Is the Process Involved In Replacing the Intermediate Steering Shaft?

It would be wise to go to the following stage if your vehicle displays any two of the aforementioned symptoms.

The steering shaft system should be completely changed out since it is the finest alternative. This is not a mechanical component of an automobile that can be mended and have 100% assured efficiency.

The best option is to replace the steering shaft system with a complete one. This is not a mechanical part of a car that can be fixed and have an efficiency that is 100% guaranteed.

The finest recommendation from a reputable vehicle repair shop will be this, only to prevent accidents with shafts.

The quality, brand, and store where the item was purchased will all have a significant impact on the price of the replacement.

There are vehicles with shafts that are incorporated into the gearbox and cars with shafts that are separate pieces that work separately from the transmission. The price may also be affected by this.

A faulty shaft replacement would typically cost between $200 and $400. The cost of the parts might be between $100 and $200, with the remaining funds going toward labor.

How to Replace an Intermediate Steering Shaft

Replacement should be extremely straightforward, and a mechanic will repair it quickly. The repair of your shaft takes one hour.

To gain access to the shaft, the mechanic just needs to move a few parts. After finding it, they will take out the damaged shaft and install a new one.

Afterward, the procedure includes replacing the components that had to be removed to have access to the shaft.

After finishing, the service technician replenishes the power steering fluid, checks to see whether the work was done correctly, and then drives the car for a test drive before handing it back to you.

To save paying for labor, you might feel compelled to repair yourself. This is not a wise decision, especially if you lack technical expertise in the entire steering system replacement process.

If you have prior expertise with this sort of work, you might only want to take on this. In any other case, it would be smart to hire a qualified technician.

Is It Safe to Drive with a Bad Intermediate Steering Shaft

You might have smoother, better control of your car thanks to a new shaft. It is no longer loose and is challenging to turn. Driving is safe for you.

You won’t need to continually replace the power steering fluid since the steering wheel becomes more accurate and dependable. You avoid spending money on upcoming repairs.

Your safety and the safety of other drivers are also guaranteed by an efficient steering shaft since you are less likely to be involved in regrettable incidents.

If proper care and maintenance are given to avoid larger mechanical difficulties related to the shaft, the positive thing about this component is that it is not susceptible to mechanical troubles.

How Long Can an Intermediate Steering Shaft Last In a Car?

This issue cannot be answered with certainty since it depends on the vehicle’s make and model as well as the conditions under which it is driven. However, it is widely agreed that if a steering shaft is maintained properly, it should last the whole life of the vehicle.

Steering column by Hundehalter / CC BY-SA 3.0. The car steering column consists of 1 steering wheel 2 cases 3 Steering columns (hidden by the case – blue dashed line) 4 Universal joints.

Having said that, several elements, such as severe wear and tear, corrosion, and impact damage, might reduce the lifespan of a steering shaft.

How Can Premature Wear of the Intermediate Steering Shaft Be Prevented?

The leading factor in the steering shaft’s early wear is improper lubrication. The steering shaft will start to exhibit indications of wear and tear far earlier than it should if it isn’t regularly lubricated.

It is critical to constantly oil the steering shaft correctly to avoid this from happening. There are various methods to accomplish this, but the best one is to use a premium lubricant created especially for the steering shaft.

This will aid in keeping the steering shaft adequately greased and shielded from accelerated wear.

How Can You Self-Replace Your Intermediate Steering Shaft?

Replacing your steering shaft is an excellent strategy to reduce the cost of auto maintenance. Although not particularly challenging, this profession does demand some knowledge. A step-by-step tutorial for replacing a steering shaft is provided here.

- The negative battery cable should be disconnected. As you work on the vehicle, this will stop any electrical shorts.

- Remove the steering column’s bolts from the dash. Usually, three bolts are used to secure it.

- Disconnect the lower steering shaft from the power steering gearbox to remove it.

- Slide the outdated steering shaft out of the car.

- Slide the replacement steering shaft into position to complete installation. Before continuing, make sure it is well placed.

- Connect the power steering gearbox’s lower steering shaft once again.

- Utilizing the three bolts you previously removed, reattach the steering column to the dashboard.

- Reattach the negative battery cable.

All there is to it is that! A fantastic approach to reducing the cost of auto repairs is to replace your steering shaft. You may do it quickly if you just follow the given instructions.

Steering system by Isawittoo / CC BY-SA 4.0. The intermediate steering shaft, a vital part of the steering system, is in charge of transferring the steering wheel’s turning force to the steering gear.

The Conclusion

Every driver and even passenger always hopes for a comfortable journey while they are in a car. Maximum comfort and confidence when driving are provided by having consistent and effective control of the steering wheel.

One of the main parts that need an urgent inspection in case of a performance issue is the steering wheel.

Despite the high expense, mechanical issues with a car’s essential components that enhance performance must be fixed right away by a competent technician. A damaged intermediate steering shaft is a critical issue that requires immediate attention to prevent further escalation of symptoms.

Get your vehicle mended as soon as you can to avoid significant issues with your safety and the safety of others, as well as to help you save money on maintenance expenditures.

Ignoring such tiny flaws might cause other components to wear out more quickly than they should. Get your vehicle mended as soon as you realize that it is exhibiting the aforementioned symptoms.

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”