Undoubtedly, everyone is aware that one of the crucial parts of your car is the transmission. This essential component is held in place by the transmission mounts. Because of this, the transmission mounts are equally essential to the transmission. Any car user must therefore grasp what it does and how things can go wrong.

Abnormal clunking sounds, excessive vibrations, and transmission movement are a few typical bad transmission mount symptoms.

The structure of the transmission mounts is often quite straightforward, yet they perform a crucial function. Although it is rare, your car could have transmission mount failure at some time throughout its lifespan.

The majority of your car’s major parts weigh a lot and need support. To safeguard it and keep the other components from vibrating, the transmission is typically mounted on a set of supports.

It’s important to replace these mounts as soon as you discover any damage to them because they might wear out with repeated use and need to be replaced to avoid further issues.

This page lists the bad transmission mount symptoms you need to watch out for as a sign that your transmission mounts are degrading. Additionally, it gives you a ballpark figure for the cost of replacing the defective transmission mount.

Finally, it will address extra pertinent issues that any driver should be aware of when it comes to keeping the transmission mount in good condition.

A Transmission Mount: What Is It?

The transmission in your car makes sure the wheels and engine turn at the same time. Without a transmission mount, the transmission is unable to do this task.

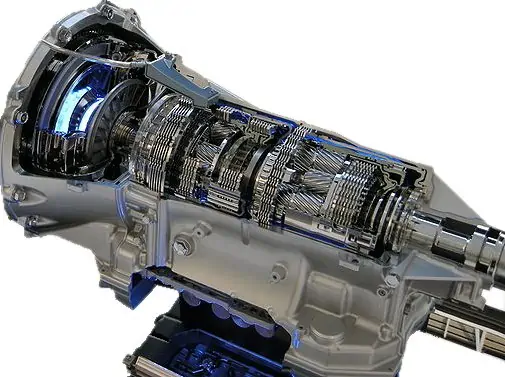

Transmission mounts are lightweight, inexpensive, compact mechanical components that play a significant role in several factors affecting driving comfort and performance. They are made out of a rubber bushing fastened to a steel gearbox mount bracket.

An automatic transmission cut by Silverxxx / CC BY-SA 3.0. The car’s transmission ensures that the engine and wheels turn at the same time. The transmission cannot perform this function without a transmission mount.

Some transmission mounts don’t have rubber parts. Some automobiles use hydraulic mounts that are filled with fluid and are made to absorb vibrations that rubber mounts cannot. Fewer individuals choose them since they are more expensive and arguably less durable than rubber choice.

Most vehicles have two or more transmission mounts because they are crucial to the performance of the vehicle. It holds the transmission to the car’s chassis no matter where the mount is placed. This is accomplished by bolting or welding the transmission’s rear support to the chassis.

Transmission mounts control engine drivetrain vibration in addition to keeping the transmission safe by making sure the links and driveshaft angles are precise. This is why the effectiveness of the transmission mounts in reducing engine vibration during the operation of the vehicle is essential.

As a result, metal parts like aluminum are used to strengthen the rubber transmission mounts. To handle the engine’s drivetrain strain, the rubber used in transmission mounts is a specially treated, extremely resilient rubber that has been temperature-optimized.

The weight of the transmission must also be supported by transmission mounts, which must also shield the passenger compartment from engine vibrations.

Although the focus of this article is not a comparison of engine mounts and gearbox mounts, it is important to note that both mount types serve similar functions and have comparable designs. Therefore, a defective engine mount can be just as damaging as a bad transmission mount.

The purpose of the transmission mount, which is either composed of rubber or fluid, is to lessen friction and contact between the engine and the vehicle’s frame. Additionally, it reduces engine motion whether the engine is operating or the car is moving.

Transmission mounts have a variety of functions, which is the problem. Because of this, they eventually begin to wear out. especially if the car has a lot of mileage. Due to excessive engine movement brought on by such wear and tear, the transmission mounts may fail, seriously harming the car.

A replacement for the gearbox mount must be ingrained in your culture of vehicle upkeep. This is because transmission mounts might fail at any time, regardless of their design or material of construction. Your driving habits could occasionally cause failed or damaged mounts.

In other cases, it can be due to normal wear and tear or a car accident. No matter the cause, you shouldn’t operate a vehicle with a subpar transmission mount. Nevertheless, you want to damage your car.

Which are the Typical Bad Transmission Mount Symptoms?

A transmission that has a working mount is a crucial mechanical part of your car. In contrast, if you don’t address a faulty transmission right away, it could result in serious vehicle damage.

Fortunately, several bad transmission mount symptoms will show up, and if you know what to look for, you might potentially save a ton of issues with your car. So, the following are some bad transmission mount symptoms to look out for:

1. Strange, Loud Sounds

Since the transmission is supported by these mounts, when the mounts deteriorate, the transmission will begin to clunk. As you speed up or apply the brakes abruptly, the noise intensifies.

Typical gear selector for an automatic transmission by Upior polnocy / CC BY 2.5. A distorted engine powertrain can cause shifting problems in the transmission. Thus, the question of whether difficult shifting could be caused by a subpar transmission mount has been resolved.

Remember that clunking sounds originating from the transmission might be caused by a variety of other things, so your best bet is to take the car to a mechanic to identify the cause.

As a general rule, any strange sounds coming from the car, whether or not they are coming from the transmission, should be attended to right away and should not be disregarded. The difficulties may be connected to straightforward problems, but they may also be connected to complex ones that demand quick attention.

2. Too Many Vibrations

As previously mentioned, the transmission mounts contain several rubber parts and an internal fluid to dampen any vibrations caused by the transmission.

All vibrations won’t be absorbed when this component malfunctions, which will cause the transmission component to vibrate quite loudly. In some circumstances, you might even detect the vibrations in the cabin of the car.

3. Strange Movements of the Transmission

Being attached to the mounts, the transmission can become loose and move from its position if the mounts start to fail.

While driving at normal speeds, you won’t notice the transmission movement, but when an expert mechanic tests the brakes, it might be obvious.

Putting your transmission under the drive and connecting it is what the braking test entails. Then you apply very slight accelerations while keeping your foot on the brake.

Make sure the car doesn’t start moving as you hit the pedal. Whether or not the transmission is moving, you’ll still need someone to keep an eye on Chuck and the engine bay.

You can also observe movement in the engine rather than the transmission. Everything nearby can adjust its location per the transmission’s motion.

4. Alignment and Vehicle-Related Problems

Since the primary function of your transmission mounts is to maintain the transmission in place, if these mounts fail, the transmission will move and may cause one side of your vehicle’s components to be heavier than the other, which will influence the alignment of other components.

You can quickly inspect your car to determine if the sides are not even to confirm the problem.

Remember that a poor transmission mount isn’t usually to blame for alignment problems. For instance, it might be connected to a problem with the wheels or tires, or even the suspension system. Therefore, you need to thoroughly inspect the car, either on your own or with the help of a qualified mechanic, to confirm the perpetrators.

5. A Thumping Transmission

Another typical sign that the transmission mounts are degrading is pumping. The beating is more of an up-and-down motion than a side-to-side action.

Any attempt to make a sudden turn can be disastrous if the connections to the transmission are harmed by this hammering.

6. Damages to the Transmission

Even while transmission damage isn’t directly associated with a faulty transmission mount, the quantity of damage is more of an effect. This transmission has a good risk of hitting other parts when it becomes loose, especially if you’re traveling at a faster pace.

It’s really easy for it to sustain damage once it starts pounding back and forth. Because of this, automobile professionals advise fixing the mounts as soon as you discover any damage to them.

Push-button gear selector by Comyu / CC BY-SA 3.0. When the Mount fails, there is a considerable chance that the transmission may slip. Furthermore, major mount issues could result in the transmission flying off the vehicle.

7. A Misaligned Engine Driveshaft

This symptom is somewhat of a chain reaction caused by faulty transmission mounts. The drive shaft of the main motor of the vehicle must be balanced and supported by the transmission mount. The transmission is harmed and the engine driveshaft is distorted when the mounts are poor.

Shifting issues in the transmission can result from a deformed engine powertrain. Thus, the question of whether a poor transmission mount can result in hard shifting has been answered.

8. Steering Problems

You may want to check your gearbox mount if you discover that you have trouble maneuvering the car around turns. Because a poor gearbox mount cannot hold the engine in place, its movement will have an impact on how the car handles turns.

For instance, a loose engine could move the car in the opposite direction of the steering wheel. The momentum of the engine will result in a weight imbalance and have a detrimental impact on how the vehicle drives.

Can Slipping Happen Because of a Bad Transmission Mount?

Yes, there is a good probability that the transmission will slip when the Mount fails. Did you realize that serious problems with the mounts could lead to the transmission falling out of the car?

Therefore, it is never advised to disregard any indication that a transmission is problematic. Because it’s a dreadful predicament you never want to put yourself in, Mount.

In What Way Does the Transmission Mount Fail?

What a wonderful question! Experts estimate that the gearbox mount will fail between 60,000 and 100,000 kilometers. Most likely, vibration or oxidation is to blame for the issue.

In general, oxidation degrades the Mount’s internal rubber parts, leading to failure. On the other side, the vibration may disrupt the Mount’s outer metal parts, which can cause damage.

It’s significant to remember that incorrect handling and lifting of the engine or transmission could also cause the Mount to malfunction. Because of this, you should never let an untrained technician work on your car, and you should try to handle as many mechanical repairs yourself.

We’ve emphasized numerous times that drivers shouldn’t attempt to cut corners on maintenance since an untrained mechanic could cause serious harm to your car. In most cases, the expense of these extra damages may outweigh the original problem.

Additionally, some severe auto accidents might result in issues with the transmission mount and the transmission as a whole. To be sure that the Mount was unaffected, you must conduct a comprehensive check even if you are not involved in an accident. Otherwise, Mount might subsequently harm the transmission.

The Transmission Mount Inspection Procedure

You should routinely inspect your car to avoid dealing with unforeseen transmission mount problems because sometimes a damaged transmission mount won’t even display any symptoms.

A manual transmission for a four-wheel-drive vehicle by Typhoon / CC BY-SA 3.0. These mounts hold the transmission in place, so when they start to fail, the transmission will start to clunk. The noise increases as you accelerate or hit the brakes suddenly.

This is so that you may avoid having to deal with vehicle issues by learning how to inspect your car’s transmission mount. How to inspect engine mounts is as follows:

1. Pay Attention to Knocking Noises

When starting or stopping the engine, keep an ear out for any knocking noises. When the engine load changes, you might also hear a knocking noise. The likelihood that the transmission is defective increases if you also observe that the engine tilts significantly when you crank the engine.

2. Look Underneath the Car

As soon as you can readily get underneath, jack up the car. Once you are underneath the car, carefully check the gearbox mounts for any missing or loose bolts or brackets. It’s possible that missing bolts or loose brackets can be repaired or replaced rather than needing to be replaced entirely.

While underneath the car, look for rubber that has deteriorated or crumbled and see if the gearbox mount is fractured or split. It would be beneficial if you kept an eye out for rubber cracks as well.

You should be ready to repair the rubber on your vehicle’s gearbox mount if you see any cracks, collapse, or rotting. a visual demonstration.

How Is the Transmission Mount Replacement Done?

Your best option would be to replace the gearbox mount if your car has displayed any or all of the bad transmission mount symptoms.

To achieve that, there are two options. Having an auto mechanic handle it would be the first option. But because replacing a transmission mount can be expensive, many people choose the second option—the do-it-yourself route.

Simply enter “engine mount replacement near me” into a search engine to find a mechanic who can replace the transmission mount on your car. That ought to make it easier for you to contact qualified mechanics in your area.

As an alternative, if you decide to change the motor mounts yourself, you will need the following high-quality mechanic tools:

- Breaker bars

- The wrenches

- Various extensions sizes

- The hammer

- The pry bars

- The flat-headed screwdriver

- The jack stands

- A bottle jack

- A wooden block

The position of a car engine in the engine bay by Carolla / CC BY-SA 3.0. A loose engine could cause the vehicle to travel counter to how the steering wheel is pointing. The engine’s motion will cause a weight imbalance and harm how the car handles.

What is the turnaround time for replacing motor mounts? Not long at all, especially after you get the hang of it. You may start replacing the defective transmission mount once you have the necessary equipment in your toolbox. This is how:

Step 1: Identify the Problematic Transmission Mount

To do this, park your car somewhere flat and stable because doing so keeps it from rolling away while you work on it. Find the mount, then spray penetrating fluid on the mount’s bolts.

Before removing the bottom bolts with a breaker bar and short extensions, give it some time to seep into the bolts. You might have to make do with two wrenches to remove the top bolt from the amount.

To accomplish this, insert the second wrench’s open end into the closed end of the one you are now using to loosen the bolt. You will receive something that has additional reach and torque, similar to an extended wrench.

Step 2: Lift the Vehicle

The next step would be to raise the car high enough so that you could easily get underneath it using the jack and jack stands. But when changing the motor mount, you must understand how to sustain the engine.

Be careful where you place the jack. Find a sturdy transmission component that won’t be harmed by the jack’s pressure. A location without a seal would be the ideal location for the jack.

Once you’ve located one, install the wooden blocks on the transmission before jacking up the car just enough to release the mount’s pressure. In this manner, the transmission mount’s already-loosened bolts can be taken off.

Once you’ve done that, jack up the car a bit more so you can remove the transmission mount with ease.

Step 3: Perform Transmission Mount Replacement

By removing the bolts at the bottom of the bracket, you can separate the mount from the bracket to which it is fastened. After that, you replace it with the new mount, making sure it fits properly. Consider applying some thread lockers to the bolts before installing them, then tightening them as firmly as you can.

To install the replacement gearbox mount, slide it into position on the car using a hammer and screwdriver to nudge it in. Because the replacement mount will be a little taller, you might have some trouble, but you should try to avoid using force because it could harm the transmission mount.

Before putting the bolts in and tightening them, jack up the car a little to ensure that the mount is properly positioned. After completing this, lower the car and tighten the nuts with a torque wrench or the previously mentioned extension wrench. This instruction can be used to create a visual presentation.

Therefore, you may be asking yourself at this point, “Should I replace all motor mounts?” You might, given that if one mount fails, the others are typically on the verge of failing as well.

Is Repairing the Bad Transmission Mount Worth It?

You should always ask yourself this question before performing any mechanical repairs. Sometimes we decide to repair it since we believe it won’t cost much money. Before making a final choice, it is advised that you stand back and conduct a comprehensive analysis of the circumstance.

A car engine held firmly on the chassis by Yones / CC BY-SA 3.0. It’s important to keep in mind that improper handling and lifting of the engine or transmission may also result in Mount issues.

First, you need to compute the entire repair expense. Take into account any required car maintenance as you proceed. Do you want to replace the mounts simply, for example, or are there other small or serious issues?

Regular maintenance is another factor to take into account. Is it time for an oil change or perhaps a tire rotation, for example?

The next step is to evaluate the total cost of repairs to the overall value of your car. It is not a good idea to fix your car if you realize that the cost of repairs will be near to or higher than 75% of its value.

Similarly, if repair charges are not going to add much to the worth of your vehicle, it is also not a smart idea to fix it. For example, if your car is currently worth $10,000 and repairs will cost roughly $7000. Do not fix it if you have concluded that after completing these report pairs, the new vehicle’s worth will not exceed $15,000.

Right now, selling your automobile and putting the proceeds toward a larger down payment on a new vehicle is your best course of action.

How Much Does a Bad Transmission Mount Cost to Replace?

The transmission mount replacement often costs betweeb $200 to $800. Remember that this range changes significantly based on the kind of car and the cost of labor.

Because it takes time and demands a certain level of mechanical skill sets, labor costs can play a significant role in the cost of changing the transmission mount.

If any other parts around the Mount were damaged, the total cost might quickly increase.

Some people would rather have someone else replace their transmission. Although it is a smart concept to save labor costs, if you have never performed this type of work before, it can be harmful.

Yes, there are a ton of guides available online, but most DIY projects don’t work perfectly the first time. As a result, you must think carefully about whether it is worthwhile to test your vehicles.

Which are the Different Classes of Transmission Mounts?

Transmission mounts exist in a variety of styles, just like any other auto component. Numerous factors influence the selection of transmission mounts by manufacturers. Let’s look at the options offered in various automobiles before we get into these.

1. Transmission Mounts Made of Rubber

The most straightforward transmission mount is this one. It is a metal cylinder that has been filled with thick rubber material. Rubber transmission mounts’ metal portion is a sturdy mount bracket that offers component strength. This metal frame is sturdy enough to support the weight of the transmission and retain it in place while the car is moving.

Transmission mounts have a difficult time supporting the transmission’s weight over bumpy roads. Strong mount brackets allow the fasteners to tighten the transmission’s grip and integrate it with the car’s frame.

Rubber transmission mounts inside the metal mount bracket use an elastic rubber substance to reduce vibrations. Vibrations from the transmission’s moving parts may reach the cabin through the mounts.

Insufficient transmission mounts can allow these vibrations to pass through the seats and raise noise and vibration levels. This results in less comfort.

An internal combustion engine was removed from a car by Till.niermann / CC BY-SA 3.0. While idling, the engine shakes more. The mounts unwind to actively absorb these vibrations. As the engine speed rises, the mounts could become stiffer, preventing the engine from moving inadvertently.

Rubber transmission mounts are a practical technique to prevent these vibrations from entering the cabin. The connecting arm of the transmission is held in place by the elastic rubber substance inside the metal bracket.

This metal component won’t be touched by the arm, minimizing vibrations. The rubber component dampens vibrations that do not reach the mount.

This minimizes these vibrations by dampening them. Rubber transmission mounts do, however, have some disadvantages, as do the majority of cost-effective systems.

Despite being muffled, some vibrations still reach the cabin. This is not a problem for economy automobiles, since the price is the main consideration. But this is unacceptable for luxury automobiles. For increased comfort, they need superior technology.

2. Transmission Mounts Filled with Hydraulic Fluid

Some high-end vehicles use hydraulic mounts in place of rubber transmission mounts to enhance their advantages. Only so many vibrations can be dampened by rubber mounts. So, this level of dampening might not be sufficient for these cars, which require the highest level of comfort.

This is provided because manufacturers can experiment with various transmission mounts because there are no severe cost restrictions in these market segments.

Similar to hydraulic engine mounts, hydraulic transmission mounts operate similarly. Both of them use a gel or liquid inside the mounts to dampen vibrations. Due to the better damping characteristics of these fluids, this is significantly more effective than a rubber mount.

They are the preferred option when comfort is a top priority due to their higher damping capability. But there are also disadvantages to this kind of transmission mount. The biggest problem, like with any modern technology, is the price.

These mounts cost more than straightforward rubber units because of their intricate construction, specialty fluid, and seal requirements.

Because of the additional expenditures, only high-end vehicles—whose markets are less price-sensitive—can use them. Additionally, hydraulic mounts are less robust than rubber ones.

The sturdy and straightforward design of the rubber mounts ensures a long product life. They do eventually need to be replaced, but they will undoubtedly outlast hydraulic transmission mounts. The hydraulic mounts also introduce the problem of leaks, which affects every fluid in an automobile.

Hydraulic mounts are only useful when comfort comes before cost and durability. Although it has fewer uses than rubber mounts, the level of comfort it offers is unmatched.

3. The Active Transmission Mounts

Active mounts, which are often used in engine mounts but are also discussed in this narrative because it is about transmission mounts, might not seem like an ideal fit. However, because engine mounts are made similarly to transmission mounts and serve the same purpose, it is useful to be aware of current industry trends.

Active hydraulic mounts are the most cutting-edge alternative on the market, followed by rubber and hydraulic mounts. Since motor mounts must dampen much greater vibrations than transmission mounts, they are the main application for this technology.

Active mounts are very much what their name implies today. To respond to the environment, they actively adjust the mount’s rigidity. The engine shakes more while it is idle. To actively absorb these vibrations, the mounts relax. The mounts may become more rigid as the engine speed increases, preventing the engine from making unintended motions.

The Conclusion

You must be able to identify the bad transmission mount symptoms as a car owner. This is because while they may not be the largest or most expensive component of your car, the gearbox mounts are crucial to a satisfying driving experience.

The purpose of the gearbox mount is to mitigate the torque that the running engine produces and prevent vibrations. So what happens if your transmission mount is damaged? When the transmission breaks down, the car’s performance suffers, and the engine may eventually sustain serious damage.

Your ability to recognize these indications can help you avoid expensive repairs in the long term and get the most out of your car.

Typical gear selector for an automatic transmission by Upior polnocy / CC BY 2.5

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”