A bent valve might happen if the timing belt is slipping or failing. Here is how to identify a bent valve. Nobody desires to deal with engine issues, but it does happen.

A bent valve is one problematic problem that can give you a headache. How significant is the issue, and what are the bent valve symptoms?

An engine that won’t start, an irregular engine while it’s idling, a lack of engine power, an engine banging noise, and excessive exhaust emissions are examples of bent valve symptoms.

Your engine’s valves are in charge of managing how much fuel and gas are delivered to the combustion chamber. A damaged timing belt or an issue with engine timing are the usual causes of a bent valve.

You shouldn’t try to start the engine or operate the vehicle if you believe you have a bent valve because doing so could seriously harm the engine’s pistons and cylinders.

Since the engine valves are a crucial component of the motor, it’s critical to resolve these issues as soon as possible.

We examine how engine valves work and briefly discuss bent valve symptoms when a valve is bent. Additionally, our article explains how to look for potential bent valve symptoms. Let’s start by quickly reviewing what engine valves are.

An Engine Valve: What Is It?

The components that aid in regulating airflow through the motor are valves. Intake valves open during the intake stroke to let air into the combustion chamber. Exhaust valves open during the exhaust stroke to let the burned combustion leave the chamber.

Both the intake and exhaust valves must remain closed throughout the compression stroke to build up pressure before the combustion mixture can ignite. Your car’s power comes from combustion force.

The intake and exhaust valves are located inside the cylinder head. Most cars have two of each type per cylinder. Consequently, a four-cylinder motor has a total of 16 valves.

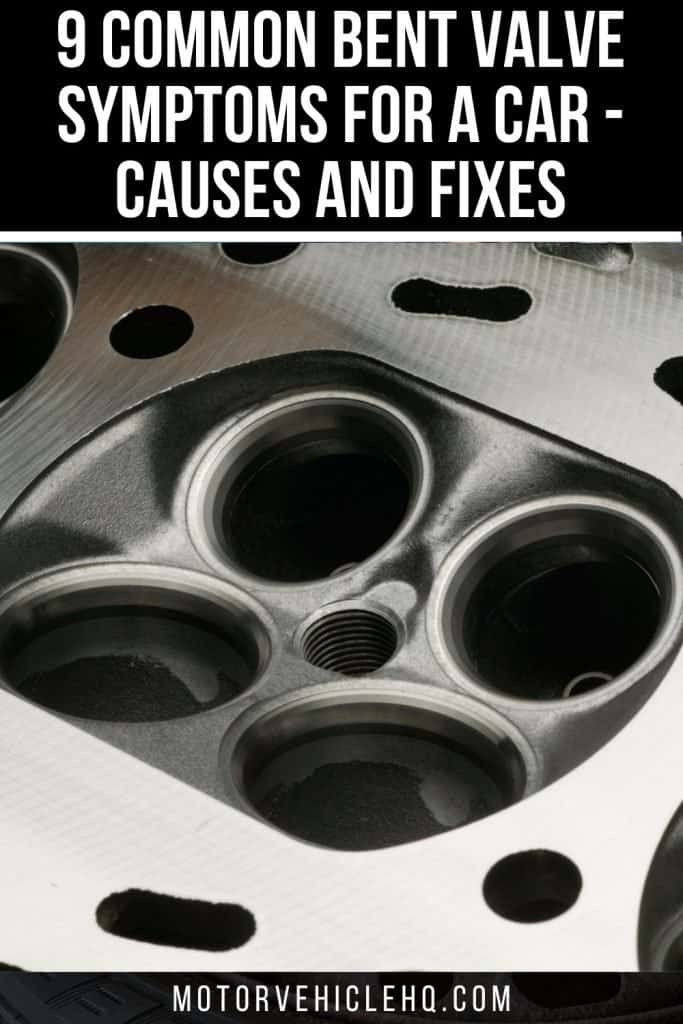

A cylinder head of a four-valve engine by Tennen-Gas / CC BY-SA 3.0. Valves are the parts that help control the airflow through the motor. During the intake stroke, intake valves open to enable air to enter the combustion chamber. To allow the burnt combustion to exit the chamber, exhaust valves open during the exhaust stroke.

However, some of GM’s LS V8 engines only have one intake and one exhaust valve per cylinder, for a total of 16 valves.

What Is the Function of Engine Valves In a Car?

Valves regulate how a fluid flows via a system. That fluid is air inside the engine of your car.

Intake valves must open during the intake stroke to let new air into the combustion chamber. Exhaust valves must open during the exhaust stroke to allow the burned combustion mixture to leave the combustion chamber.

The intake and exhaust valves must both be closed during the compression stroke to store potential energy before the combustion mixture ignites. Your vehicle’s power comes from this combustion force.

Intake valves and exhaust valves are common features of automobiles with internal combustion engines. The cylinder head contains these valves (s). A four-cylinder engine would have 16 valves overall (2*2*4 = 16) since each cylinder typically has two intake and two exhaust valves.

The LS engines used in Corvettes (the LS3, LS4, and LS5) only feature one intake and one exhaust valve per cylinder, for a total of 16 valves, compared to the 32 valves found in the majority of contemporary V8s.

What Causes Bent Valve Symptoms to Occur?

What causes bent valve stems? The valve stem in your car could bend for several reasons. These are the most frequent reasons.

1. A Misaligned Engine Timing

The ignition timing, which instructs the spark plugs when to ignite, is sometimes referred to as an engine’s “timing.” Timing can also relate to the engine’s mechanical cam timing. As the crankshaft turns, the cam timing instructs the valves when to open for each cylinder.

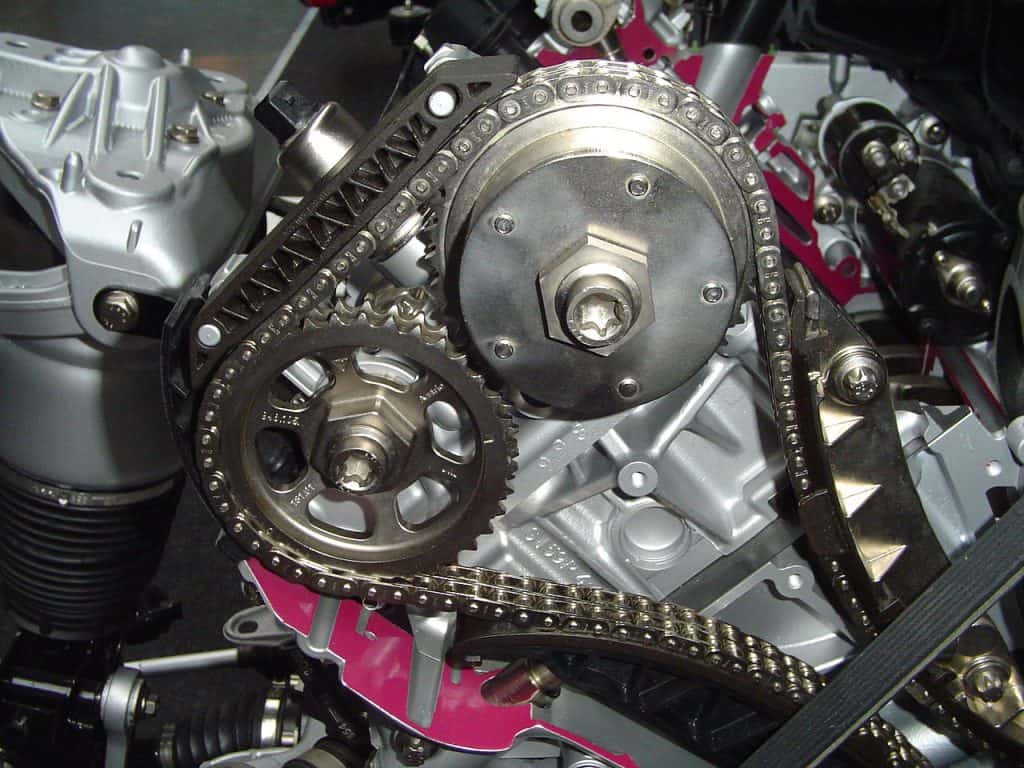

A set of pulleys and sprockets are typically used to drive a timing belt or timing chain that controls cam timing. Each cam is turned at a fixed ratio to the camshaft rotation by a belt that is rotated by the crankshaft.

If the engine’s cam timing is off, the pistons in many engines may come into contact with the valves. The term “interference engine” refers to this structure.

Regardless of timing, a non-interference engine has valves and pistons that are sufficiently separated from one another to prevent any possibility of contact.

It is quite simple to bend a valve on an interference engine if the timing belt or timing chain is replaced but the engine is not timed properly.

If you’re changing a timing belt by yourself, you must adhere to all guidelines provided by the vehicle’s manufacturer in the official service manual. Before you tighten everything back up, manually turn the engine over a few times to check sure no internal parts are contacting.

2. Engine Running Too High

The engine’s redline is established by the car’s manufacturer based on a variety of variables. For instance, the engineer’s design and stress test of the engine may take into account the weight and balance of the rotating assembly, the durability of the valve springs, heat, harmonics, and the available oil supply. Even the transmission could have an impact on this choice.

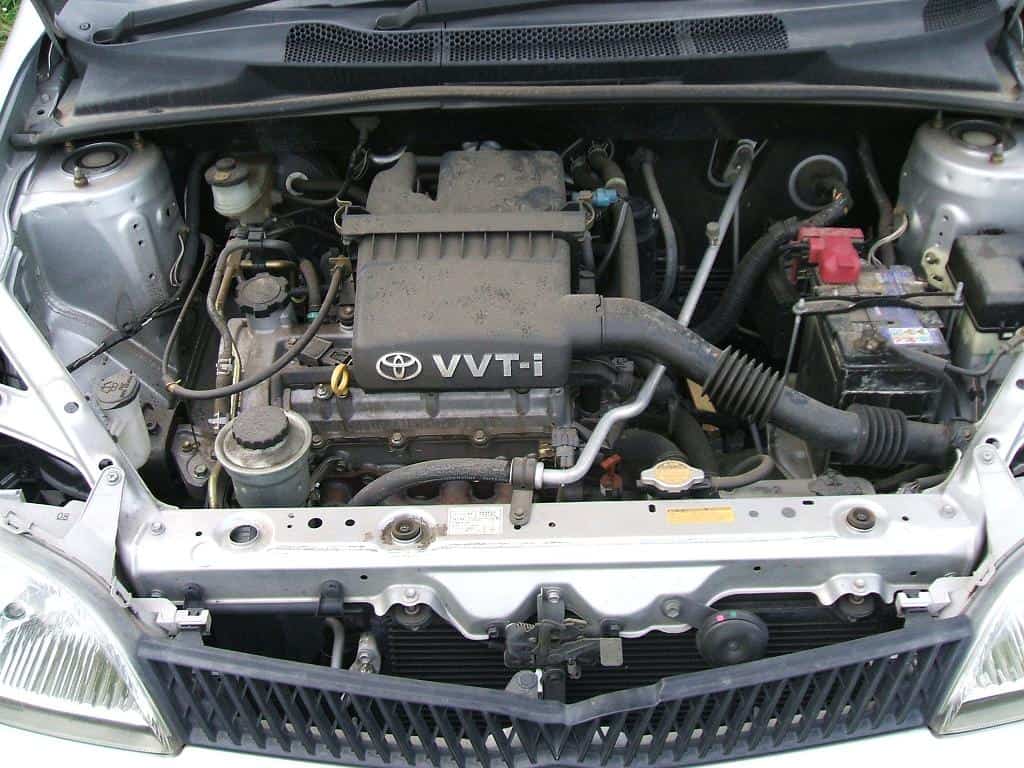

A car engine by Carolla / CC BY-SA 3.0. Examples of bent valve symptoms include an unwilling engine to start, an erratic engine when it is idling, a lack of engine power, an engine banging noise, and excessive exhaust fumes.

In cars with manual transmissions, downshifting into a gear that is too low for the pace the automobile is going at can cause the engine to rev higher than it should. This costly error, also known as a “money shift,” might cost you an engine.

There is nothing the ECU can do to prevent you from seriously damaging the mechanical components if you engage the clutch when the wheels are turning too quickly for the selected gear. After all, the transmission computer on a stick shift is your brain.

Unless you replace many of the engine’s internal components, it’s generally not a good idea to run the engine past the manufacturer’s redline. Each make and model will require a different set of improvements.

In most cases, it is impossible to overrev the engine in automobiles with automatic gearboxes (including CVTs). The transmission control module (TCM) in these cars ought to stop you from revving the engine harder than what the automobile was built to handle.

3. Inadequate Lubrication

Your engine’s health depends on the quality of the engine oil. Numerous issues could arise if the engine oil level is too low to give sufficient oil pressure to the entire engine. One of these issues is a valve being stuck in the valve guide, which could cause the valve to bend if it protrudes and comes into touch with a piston.

The cost of fixing oil starvation-related issues is generally high, but checking and maintaining your oil level is extremely affordable. Remember to complete this important step when owning a vehicle.

In extreme circumstances, inadequate lubrication can make an engine’s valves drag inside their guides, perhaps leading to valve/piston contact. This can also happen when an engine’s oil has degraded as a result of repeated failure to perform the necessary maintenance.

4. Engine Overheating

It has also been reported that extreme or sustained engine overheating can destroy valves. Intake and exhaust valves, among other internal engine parts, may warp as a result of this overheating.

5. Timing Chain or Timing Belt Failure

A very good likelihood exists that a piston will make contact with a valve and bend it if the timing belt on an interference engine were to fail. This is just one of the important causes for timely timing belt replacement.

Timing belts typically function well until they don’t. Before a timing belt snaps, there may be absolutely no warning. A broken timing belt will at the very least leave you stranded.

Except in cases where a timing chain tensioner is malfunctioning, timing chains typically don’t need any maintenance.

Which are the Common Bent Valve Symptoms In Cars?

Even on older, higher mileage engines, a bent valve is not a common occurrence. Problems with burnt valves or valve seals are more frequent. These issues are frequently brought on by a gasoline mixture that isn’t right or an engine that has been performing poorly for a while.

When there is a significant issue with the timing of the engine, a bent valve occurs. Timing belt or chain failure is the most typical reason for this.

It may also happen if the timing belt slips and moves the camshafts and valves out of alignment.

Compression testing and cylinder head removal are the two best ways to identify a bent valve.

An engine control unit (ECU) by Mgiardina09 / CC BY-SA 3.0. When the bent valve issue is detected, the ECU may overcompensate by changing how much gasoline is delivered to the cylinder. When the cylinder runs rich, unburned fuel pours into the exhaust and makes a popping or backfiring noise.

There are a few indicators to look out for if you are aware that an engine’s timing has been a problem and believe that the valves may be damaged.

The following signs of mild valve damage are present.

If you think the valves may have suffered major damage, you shouldn’t try to start the engine until you’ve done more research on the issue.

1. Loud Backfiring or Popping Noise Coming from the Exhaust

The effectiveness with which exhaust fumes can be released from a cylinder will be impacted by a bent valve of the exhaust. Engine cylinders run at extremely high pressures, and to maintain the proper pressure, exhaust valves must open and close at regular intervals.

The exhaust bent valve will no longer fit into the cylinder properly and may not close with a pressured seal if you have one. Due to the exhaust leak that will result from this, fuel combustion will almost probably be impacted.

The amount of fuel delivered to the afflicted cylinder may be adjusted by the ECU in an attempt to overcompensate if it notices a fault with the fuel combustion process. This might cause a cylinder to run rich and let unburned gasoline out of the exhaust.

Particularly when the engine is under strain, a rich engine coupled with an exhaust cylinder leak can cause backfiring and popping sounds.

2. Cylinder Compression Is Low Especially at Idle

Low compression in the impacted engine cylinder is one of the traditional bent valve symptoms. When an engine is running, it has low compression, which affects the pressure inside the cylinder. Low pressure will have an impact on the combustion process since the fuel won’t ignite or burn effectively, which will result in low engine power.

In most cases, a bent valve will result in poor compression because it won’t close tightly enough to provide a reliable seal with the cylinder head. As a result, air or exhaust fumes return to the manifold.

An engine leak-down test is a simple way to verify suspected low compression.

3. Idling Causes the Engine to Shake and Cut Out

As was previously said, a bent engine valve will impact how effectively (or even whether!) an engine runs. The performance of the engine will be impacted if one or more valves have been damaged, especially while the engine is idling or operating at low speeds due to things like a broken timing belt.

After the damage to the engine valves, the engine may shudder, cut out, and generally perform poorly due to cylinder leaks and reduced fuel combustion efficiency, to name just two of the causes. You might be able to keep driving the car until it completely stops running, depending on the extent of the valve damage.

4. Increased Use of Oil

Engine valves need to always be oiled. To lubricate the valve stem as the engine goes up and down, all engines utilize a valve seal. The valve keeps the oil constantly below the head of the valve by preventing it from entering the engine cylinder.

When the valve is bent, the seals can be worn out or damaged. Every time the valve opens and shuts, a faulty valve seal will let a tiny quantity of oil into the combustion chamber; this oil will burn off as part of the combustion cycle.

A timing chain (installed around the two circular cam sprockets) by Kolossos / CC BY-SA 3.0. If the timing belt or timing chain is changed but the engine is not properly timed, it is quite easy to bend a valve on an interference engine.

It’s bad if engine oil enters the combustion chamber. If left unchecked, it can lead to issues with the catalytic converter in addition to increasing oil consumption and negatively affecting how the engine performs.

5. Inadequate Engine Power

Engine power loss is among the most typical bent valve symptoms. There are several possible causes for this, and if it is not fixed, it could worsen over time.

Because there is less pressure in the damaged engine cylinder, a bent valve will mostly result in a decrease in engine output.

A bent valve that no longer completely closes or does not lie flat in the valve seat may be the source of this issue. Additionally, if the engine runs rich, it may result in damage to the valve head.

6. Fuel Consumption Increases, Causing the Engine to Operate Poorly.

Another frequent cause of bent valve symptoms is increased gasoline usage. As we’ve already seen, a bent valve can have an impact on the combustion process, making it significantly less effective due to a drop in cylinder pressure as well as the fact that the valves no longer function smoothly.

The ECU may read this drop in efficiency as a lack of fuel, in which case it may adjust the fuel-to-air ratio in response. The engine runs rich as a result of this increase in fuel consumption.

The ECU may also attempt to change the timing of the inlet valve if the engine has variable valve timing to increase efficiency. The intake system’s bent valve may result in the OBD error code P0011 if the ECU interprets the issue as a camshaft timing issue.

7. Engine Making a Loud Ticking or Knocking Noise

A banging or ticking noise coming from the engine is another fairly prevalent cause of bent valve symptoms.

The environment in which the cylinder head operates, along with the valves, tappets, and lifters, has tolerances that are measured in millimeters. Damage to the valves can interfere with the alignment and smooth operation of nearby components. Unusual noises from the top of the engine will invariably result from this.

Some engines, as they age, start to make a ticking sound that’s frequently mistaken for broken valves. Instead of the valves themselves, this noise is typically brought on by wear on the valve lifters.

Instead of knocking or clicking when the engine is running, worn lifters typically generate a ticking sound. When the engine heats up, the noise frequently disappears and normally has no impact on how the engine operates.

8. The Check Engine Light Illuminates

To ensure that the engine of your automobile is performing at its best, modern cars continuously check all of its sensors. Your dashboard’s check engine light will turn on if any sensor is malfunctioning or if any parameter is out of range.

The check engine light will come on if you have a bent valve. Using an OBD2 scanner, examine the fault codes to see if any are related to the air-fuel combination.

Since the engine valves are not computerized, the error codes won’t specifically state that an engine valve is bent, but they might include misfires or an incorrect air-fuel ratio.

The car exhaust system by Alexander Migl / CC BY-SA 4.0. If an exhaust valve is bent, it can land in the wrong place. When closed, it could also not seal correctly. This defect causes an exhaust leak, which modifies the fuel’s combustion.

9. Backfires on the Engine

The way the exhaust gases leave the cylinder is impacted by a bent exhaust valve. To guarantee the proper level of pressure is constantly present, the exhaust valves must open and close at precise intervals.

An exhaust valve that is bent may end up in the incorrect location. Additionally, it might not properly seal when closed. This flaw results in an exhaust leak, which alters how the fuel burns.

The ECU may overcompensate by altering how much gasoline is delivered to the cylinder when it detects the issue. Unburned fuel flows into the exhaust when the cylinder runs rich, producing a backfire or popping sound.

How Can You Diagnose Bent Valve Symptoms?

There are a few quick techniques to identify the issue if you think your engine’s valves may have become bent or broken but don’t want to pull the engine down just yet.

Step 1: Test the Engine’s Pressure

There are two straightforward tests you may run to determine the state of the engine’s interior.

Engine compression testing is the first. The engine’s ability to successfully generate pressure in each cylinder is being tested with this exercise. The test is performed by hooking up a specific engine pressure gauge to each cylinder individually, cranking the engine a few times, and taking a pressure measurement.

Engine to engine can differ in the optimum pressure inside the cylinder. Generally speaking, pressure readings from gasoline engines should range from 80 to 125 PSI. If the engine is worn, there might be a variance in the cylinder pressure, but it shouldn’t be more than 10 to 15%.

If you believe there may be a bent valve, a compression test is a wonderful place to start. It can help you determine whether the engine’s timing is adjusted properly and the state of the valves, valve seats, and piston rings.

Step 2: Conduct a Leak-Down Test on the Engine

The engine’s ability to hold pressure in each cylinder is the subject of the second type of test you can do.

Similar to a compression test, this is carried out by pumping pressure into each cylinder instead of starting the engine with a specialized engine leak-down tester tool.

The piston for the cylinder you are testing must be at the top dead center to conduct an engine leak-down test. This guarantees that the valves are closed and that the cylinder is configured so that leakage should be kept to a minimum. Any leak that is discovered can be traced to the valves’ wear or deterioration.

The air is typically fed into the cylinder by a compressed air source until the pressure surpasses 100 PSI. The leak-down tester is attached to the cylinder via the spark plug hole (this depends on the engine).

The leak-down tester contains two gauges: one that displays the cylinder’s internal air pressure, and the other that displays the percentage of air loss from the cylinder, which should be less than 20%.

Step 3: Disassemble the Engine for a More Thorough Inspection

You must determine whether a valve issue is fixable if the pressure and leak-down tests show that there is one.

Before you disassemble the engine, you might be able to identify the precise cause of the issue if the leak-down test showed a leak.

A check engine light or malfunction indicator lamp (MIL) by Wikiuser100000 / CC BY-SA 3.0. If a valve is bent, the check engine light will illuminate. You can check the trouble codes with an OBD2 scanner to determine if any are associated with the air-fuel mixture.

Following the discovery of the leak’s origin, the engine must be disassembled to examine the condition of the pistons, cylinder heads, valves, and valve seals.

How Can You Test for Bent Valve Symptoms?

The optimum check would necessitate removing the cylinder head and inspecting the valve physically to check for bent valve symptoms. Compression testing and leak-down tests are useful because they require more work than the majority of users want to put in.

A compression test allows you to easily determine the amount of compression that each cylinder produces. It’s an easy technique to determine how well the engine is working.

The leak-down test will be conducted if you discover that one cylinder is low. You can detect when the engine is leaking air using this diagnostic. The spark plug hole is connected to the leak-down test.

The crankshaft is then spun till the cylinder reaches the compression stroke that is completed. You can hear the engine’s air flowing out at this point.

You most likely have a bent intake valve if the air is coming from the intake. On the other side, the exhaust air indicates a bent exhaust valve.

However, the air entering from these places might also indicate that the valves just have carbon buildup, which results in a poor seal. If you are unclear, a certified mechanic may need to perform more diagnostics.

How Much Does It Cost to Fix Bent Valve Symptoms?

Replacement is the sole “correct” solution for bent valve symptoms. As it necessitates the removal of an engine’s cylinder head, this is a somewhat complex repair.

As a result, labor expenses are frequently rather high. A broken valve’s “head of” repair will typically cost between $800 and $1,500.

However, if you withdraw and restore the damaged cylinder head yourself, this cost can be greatly decreased. In these conditions, the price of replacing a valve would probably be closer to the $400–600 mark.

Several valve repair techniques have been used without removing the damaged cylinder head. Most involve using compressed air to pressurize a cylinder before attempting to physically straighten a bent valve with force.

Although a repair of this kind would be considerably less expensive, attempts of this kind are not recommended because they are likely to degrade the “repaired” valve. The technique can also result in damage to the corresponding valve guides and valve seats.

How Can You Fix a Bent Valve?

It’s crucial to have the bent valve in your engine fixed as soon as you can. A bent valve can seriously harm an engine and potentially result in engine failure.

Identifying the bent valve is the first step. Both a compression test and a visual inspection of the valves can be used to accomplish this. To do a compression test, you must take out all of the spark plugs from the cylinders and then repeatedly crank the engine.

Each cylinder’s compression needs to be tested. Low compression in one cylinder is a sign that there is a bent valve in that cylinder.

You must remove the cylinder head after figuring out which valve is bent. This is a rather challenging task that calls for specialized equipment. It is advised to take the car to a mechanic if you are unsure about doing this repair.

The engine cylinder head by Kauczuk / CC BY-SA 3.0. Identifying which valve is bent requires you to remove the cylinder head. It takes specialist equipment to complete this pretty difficult process.

The bent valve can be changed once the cylinder head has been removed. Making sure the new valve is placed properly and that all of the seals are in place is crucial. If not, there can be additional engine damage.

While this repair might be time-consuming and challenging, it is crucial to address a bent valve as soon as feasible. You risk causing major engine damage if you don’t.

How Can You Replace a Bent Valve?

- Remove the spark plugs from each cylinder, then turn the engine over again to let off any trapped pressure.

- Find out which cylinder has poor compression by doing a compression test. This can be bent valve symptoms.

- Taking off the cylinder head This is a challenging task that calls for specialized equipment. It is advised to take the car to a mechanic if you are unsure about doing this repair.

- The bent valve should be replaced with a new one. Make that all of the seals are in place and the new valve is placed properly. If not, there can be additional engine damage.

- Install the cylinder head and tighten it to the correct torque values.

- Replace the spark plugs, then start the engine to check for leaks.

The repair of a bent valve should be done as soon as feasible even though it can be challenging and time-consuming. You risk causing major engine damage if you don’t.

The Conclusion

Although we sincerely hope that the engine of our car will never need to be repaired internally, such problems are always a possibility.

It is crucial to comprehend the whole depth of the scenario at hand because fixing problems of this sort can be fairly expensive and involved.

One concern with internal engines that needs more research is one or more bent engine valves (intake or exhaust). This kind of damage can stem from several underlying problems, some of which are more common than others.

Nevertheless, identifying the various signs of such damage is the first step in fixing an engine that has one or more marginalized valves.

This makes it possible to choose the optimal course of action going forward, whatever that may entail in a particular circumstance.

A cylinder head of a four-valve engine by Tennen-Gas / CC BY-SA 3.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”