Synchronization is one of the least understood and most frequently misinterpreted complaints and issues with manually shifted gearboxes and transfer cases.

Because there are so many gear ratios in a manual transmission or transaxle, several shafts and speed gears are moving at various rates. The transmission features several synchronizer components that engage the required speed gear in the direction of the driver to shift gears without gear clash.

The opposing gears that set the ratio for each speed the driver can choose are constantly meshing with the speed gears. The synchronizer assemblies are splined to the shafts to which they are installed, and the speed gears freely spin on the shafts to which they are attached.

The design is developed to make the speed gear chosen to move at the same speed as the shaft and synchronizer assembly since synchronization refers to having numerous things happen at the same time.

The sliding sleeve of the synchronizer assembly can be engaged to the speed gear being selected when the shaft speeds are equivalent without grinding or clashing. This procedure must function both during upshifts and downshifts, synchronizing the various shaft speeds with exact time at various throttle openings.

The synchronizers’ performance is impacted by a variety of factors, which might lead to shift-related issues. Numerous of these factors are not related to transmission.

The technician must comprehend both the theory of operations and the relationships between the parts of a manual gearbox to diagnose and repair the transmission correctly and provide the client with a nice, smooth-shifting final product.

When compared to the intricacy of an automatic gearbox, manual transmissions are comparatively simple machines, but contemporary versions still contain a multitude of pieces that might go wrong. While the majority of manual gearboxes are sturdy, synchronizer (or “synchro”) wear is a typical problem on many older or higher mileage transmissions.

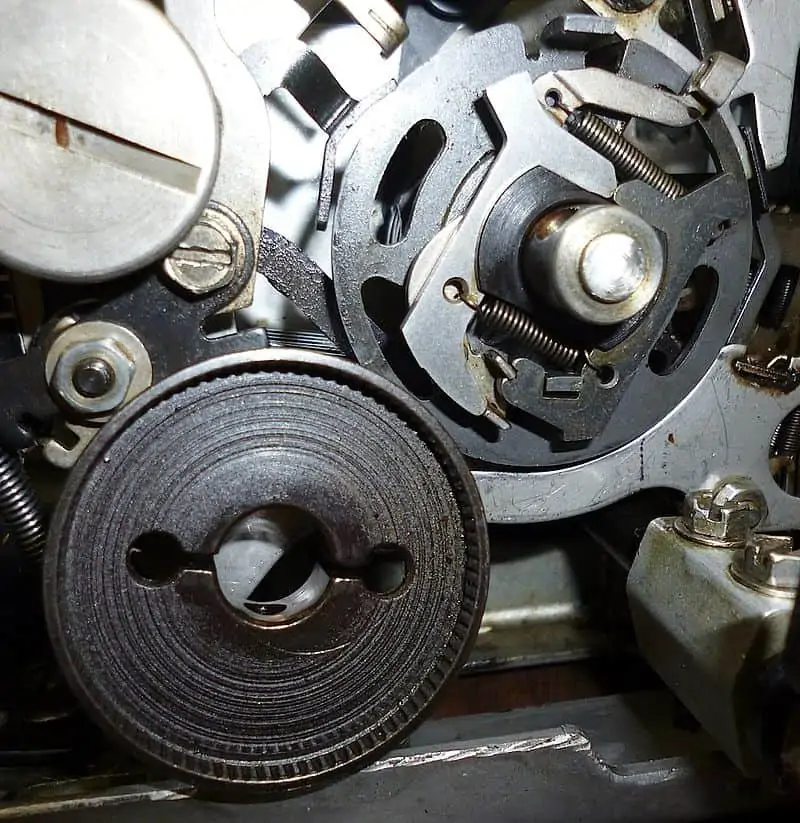

Car manual transmission by Typhoon / CC BY-SA 3.0. Manual transmission or transaxle has a large number of gear ratios, which causes several shafts and speed gears to move at different speeds. To avoid gear clashes, the gearbox has many synchronizer parts that engage the necessary speed gear in the driver’s direction.

Your gear synchronizers make it possible for your gearbox and engine to run at the same speed, reducing jarring or severe grinding and eliminating the need for double-clutching and exact rev-matching.

Synchros are a modern manual gearbox invention that, like many others, simplifies your life and enhance your driving experience. Stick-shift vehicles are popular because they offer a satisfying driving experience, so it may be extremely annoying when a defective synchronizer prevents clean smooth shifting.

What Is a Manual Transmission Synchronizer for a Vehicle?

If you’ve ever operated a manual transmission vehicle, you are aware that shifting gears is not always a seamless process. You can have trouble shifting gears because it feels stuck in the middle of gear or it requires a little prodding. Altering gears may also cause the car to lag for a brief period or even splutter a little.

The installation of a synchronizer to the manual transmission is one advancement achieved through time. A synchronizer makes the manual gearbox run more smoothly, enabling quicker acceleration and simpler gear changes.

The synchronizer facilitates smoother transmission operation while also lowering transmission wear and tear, which may help you save a lot of money over time.

Where Is the Manual Transmission Synchronizer Found In a Car?

The input and output shaft speeds of a manual gearbox are synchronized by a part known as a synchronizer.

This part, which is situated in between the clutch and the gearbox, aids in ensuring seamless gear changes. Without a synchronizer, switching gears would be challenging since the gears would not be in sync.

A broken synchronizer might be the cause of your manual transmission car’s trouble shifting gears. This part should be checked out and fixed if necessary because it might impact how well your car performs as a whole.

How Does a Manual Transmission Synchronizer Operate In a Car?

A manual gearbox has a challenging design. In essence, a set of gears on an output shaft engages with a set of gears on a countershaft.

A slider, also known as a shift sleeve, slides across the gear you have chosen and secures it to the output shaft as you shift gears.

As you shift, a synchronizer modifies the shaft’s speed to make the gears align more rapidly. The slider presses against the synchronizer’s keys or balls, which in turn press against the blocker ring.

The friction created when that ring presses up against the gear’s cone aids in balancing the shaft speeds. When the shaft speeds are equivalent, the block’s notches line up, and the slider’s teeth engage the block ring.

The entire process runs more smoothly, improving performance and decreasing transmission wear and tear.

Manual transmission synchronizer rings by A7N8X / CC BY-SA 3.0. Your gear synchronizers enable your gearbox and engine to operate at the same speed, minimizing jarring or severe grinding and getting rid of the necessity for double-clutching and precise rev matching.

What Causes a Manual Transmission Synchronizer to Fail?

If you’ve been operating a stick shift for some time, you’re undoubtedly accustomed to how your gear lever feels while shifting into gear. The synchros offer the speed matching required for the collar to engage smoothly when you shift the selector from gear to gear.

When the collar and gear speeds are in harmony, that tugging feeling happens. The synchronizer is straining to match speeds if you have ever experienced resistance when pulling the gear lever.

What causes synchronizers to malfunction in the first place? It could just be the consequence of regular wear in gearboxes with very high mileage. Every time you change gears, your synchronizers are subjected to some damage and will eventually deteriorate. Bad synchronizers are more frequently the consequence of user mistakes.

Your synchros may prematurely fail if you quickly change into gear since you are placing extra strain on them. Wear of this kind frequently develops as the clutch (or another clutch system component) fails, and gearshifting can become challenging as a result.

Which Ones are the Common Manual Transmission Synchronizer Problems?

A synchronizer synchronizes the input and output speeds of a manual gearbox.

This component assists in the transmission’s smooth operation and is located between the clutch and the transmission. It would be challenging to change smoothly since the gears are not in sync with one another.

In a vehicle with a manual transmission, a faulty synchronizer might be the reason for shifting gears irregularly. This part should be inspected and, if required, fixed since it might impair the performance of your car.

The synchronizer, which is a part of the gearbox, keeps the gears in sync during shifting.

This component is crucial because the transmission might suffer significant damage from misaligned gears. The synchronizer in manual transmissions is prone to many problems.

The typical manual transmission synchronizer problems include;

1. Damaged Gear Teeth

As gear teeth deteriorate over time, they become less able to mesh correctly, which causes the gears to grate against one another. As a result, the synchronizer and other transmission parts may sustain damage.

2. Synchronizer Rings That are Broken or Stuck

The teeth of the gear cannot properly engage because the synchronizer rings are damaged or stuck. This may also harm the transmission.

3. The Synchronizer Containing Debris

In the synchronizer, dirt and metal shavings might prevent the gears from correctly meshing. This might potentially cause harm to the transmission.

The car engine by Tennen-Gas / CC BY-SA 3.0. It may be difficult to keep your car’s engine and gearbox speeds in sync if your synchronizers are damaged. Driving may be difficult as a result of this, and the engine or gearbox may also be harmed.

What are the Symptoms of a Faulty Manual Transmission Synchronizer?

A vehicle’s manual transmission depends heavily on gear synchronizers to function. By modifying the speed of the shaft so that the slider may mesh with the next gear, they are in charge of aiding the seamless engagement of gears. By doing this, the gears in a manual gearbox may align throughout the shifting operation swiftly and efficiently.

To guarantee that you can drive your car safely and stop future damage, it’s critical to solve any problems with your gear synchronizers as soon as possible. To help you detect and address any difficulties as quickly as possible, we’ve included some of the most typical indications that a gear synchronizer isn’t working properly below.

1. Unusual Noises from the Transmission

Your car’s gearbox may begin to produce odd noises if your gear synchronizers are worn out or otherwise broken. When a gear synchronizer malfunctions, you may frequently hear grinding noises while downshifting or in a particular gear.

But since there are many other possible causes for your transmission’s weird noises than broken gear synchronizers, it’s crucial to get your car checked out by a professional so they can accurately identify the problem.

2. Having Trouble Changing Gears

Since smooth gear changes are made possible by gear synchronizers, difficulties shifting gears is a clear result of old or broken gear synchronizers. Get your gear synchronizers checked out if you struggle to transfer the shift lever from one gear to another.

3. Vehicle Transmission Remains Stuck In Gear

Sometimes you won’t be able to change gears at all due to malfunctioning synchronizers. More specifically, the problem could be brought on by a jammed synchronizer sleeve. You will need to tow your vehicle to a repair shop so they can find the cause of the problem and fix it because it will be dangerous to drive.

4. Transmission Shifts Abruptly to Neutral

The transmission jerking into neutral is another indication of faulty gear synchronizers. You may have worn gear synchronizers if, after shifting into gear, the gearbox abruptly shifts into neutral while you’re driving.

The slider will be unable to mesh with the appropriate gear when the gear synchronizers are worn down, which might cause your transmission to suddenly shift into neutral.

Fortunately, symptoms caused by poor synchronizers are usually pretty obvious. The two most typical signs are gear popping and grinding. Each gear has its synchronizer, therefore problems are often isolated to one or more specific gears.

For instance, if you grind every time you shift into second gear, your second gear synchronizer is probably worn out. The gear selector frequently popping out of one gear is another indication that your synchronizer is failing.

Even though the earliest signs of a poor rhythm are typically not severe, the issue will only worsen over time. By continuing to drive with poor synchronizers, you run the risk of harming the gears themselves.

How Can You Repair a Defective Manual Transmission Synchronizer?

In a manual gearbox, a component called a synchronizer synchronizes the input and output shaft speeds. This component, which sits between the clutch and the gearbox, helps to guarantee smooth gear shifts. It would be difficult to change gears without a synchronizer since the gears would not be in sync.

Unfortunately, rebuilding the transmission is always required to replace a faulty synchronizer. Fortunately, fixing a manual gearbox often costs less money and requires less effort than doing it for an automatic transmission.

Even while you may expect to save some money on the rebuild if the indications indicate synchronizer failure, you should still prepare to pay over $1,000 on the repair. Repairing a defective synchronizer is essential for the functionality and durability of your transmission, regardless of the cost.

How Much Does It Cost to Fix Manual Transmission Synchronizer Problems?

It’s unpleasant to have issues with your transmission synchronizers, but fortunately, these issues can often be resolved quickly if discovered in the early stages. First, determine whether your manufacturer’s warranty will cover the gearbox problem. If not, you’ll need to set aside money for repairs.

It is challenging to predict the cost of synchronizer repair since it will rely on how challenging it is to identify the problem and the degree of the damage. Costs for transmission repairs range from $300 to $3000.

Synchronizers typically fall on the lower end of the repair cost spectrum, but if the part is difficult to access, the cost may increase. It could be time to consider replacing the transmission if the issue is serious or if it has hurt other transmission parts.

Having it examined by a transmission specialist is the best method to obtain an accurate diagnosis of any transmission issues and a reliable estimate of the cost of repair.

Can You Drive Without the Manual Transmission Synchronizer?

The synchronizer is one of the most important parts of a car’s powertrain. As a result, power is effortlessly and smoothly transferred to the wheels.

Without synchronizers, shifting gears would be exceedingly challenging since the gears would constantly rub against one another, wearing down the gearbox.

Most vehicles include synchronizer rings that keep the gears aligned. These rings link the bearings and gears. By ensuring that the gears are correctly aligned, they assist in the efficient transfer of power.

What Occurs When a Manual Transmission Synchronizer Fails?

The entire system is in danger in the case of a synchronizer failure. Even if it doesn’t, if it does break, a transmission failure is conceivable.

If you have any cause to think your synchronizer is broken, fix it straight immediately. Avoid attempting to solve the issue on your own; it will require a high degree of competence, and you risk making matters worse.

Schedule a visit with a skilled technician to have the synchronizer inspected and fixed. If you don’t, you could suffer severe harm or perhaps a system breakdown. If you notice any problems with your synchronizer, act right away!

How Many Miles Can a Manual Transmission Synchronizer Last?

How durable are the synchronizers in a manual transmission? There isn’t a conclusive solution to this problematic issue, which is terrible. While some drivers claim their synchronizers have only lasted for a few thousand miles at best, others claim theirs have lasted the whole lifespan of their vehicles.

Normally, the driver pushes the clutch before moving the shifter knob to change gears. When double clutching, the driver depresses the clutch and then uses the shifter knob to go to neutral. The driver then chooses the proper gear for the vehicle and presses the clutch pedal once again.

The weight of your vehicle, your driving technique, and the state of the roads all have an impact on how long your synchronizers survive. The last two conditions largely impact the lifespan of the synchronizer.

On the other hand, synchronizers are durable and can resist a large amount of wear and tear throughout their service life, according to the majority of automotive specialists. People who like long-distance running might wish to give them a try.

Think about the factors mentioned above to get an idea of how far they’ll endure. Never forget to ask a professional for help if you have any worries or questions.

How Should You Drive a Car with Manual Transmission Synchronizer Problems?

Driving a vehicle that has faulty synchronizers might be difficult. You must engage the clutch in a manual transmission to match the engine RPMs to the gearbox speeds.

If your vehicle has an automatic gearbox, you will need to use the accelerator and brake pedals. By changing gears, make sure the gearbox is in the appropriate gear.

If your synchronizers are broken, it could be challenging to maintain your car’s engine and transmission speeds in sync. This can make driving difficult and harm the engine or gearbox, in addition to making driving difficult.

If your car’s synchronizer is giving you trouble while you’re driving, it could need to be fixed or replaced.

Don’t attempt to drive a gearbox with a synchronizer issue carelessly. Create a strategy to deal with the current challenge.

Is Shifting Possible Without a Manual Transmission Synchronizer?

Although synchronization is one option, shifting is not a one-way path. Some shifters may be able to shift without synchronizers, although it may take some practice.

Here are some tips if you wish to try shifting without synchronizers. To make the most of synchronizers, you need to be aware of the following things:

One way to communicate with people is to pay attention to how your vehicle is moving. To determine when to change gears depending on how your vehicle travels, try to stay in step with what your vehicle is doing.

Get some experience first. As you practice more, shifting without synchronizers gets simpler. No matter how long it takes you to get the hang of anything, don’t allow it to get you down.

Don’t shift without synchronizers, even if the aforementioned advice has convinced you that it is possible. Instead, get your car fixed to ensure the durability and dependability of the transmission over the long run.

What Is Double Clutching In a Manual Transmission Vehicle?

In the past, double clutching was utilized to accomplish the same goals as a manual transmission synchronizer.

Your gearbox will ultimately wear out no matter what you do. However, by maintaining your gearbox, reducing wear might help you save money over time. Search for a vehicle with a manual transmission synchronizer as one such safety measure.

When changing gears normally, the driver depresses the clutch first before turning the shifter knob. When double clutching, the driver depresses the clutch before shifting to neutral using the shifter knob. The driver then depresses the clutch pedal once again and selects the appropriate gear for the car.

It helps the car change to gear more smoothly and lessens transmission wear and tear. Double clutching achieves some of the same effects as a synchronizer.

How Can You Keep Your Manual Transmission In Good Shape?

No matter what you do, your transmission will eventually become worn down. However, preventing wear can help you save money over time by preserving your gearbox. One such precaution is to look for a car with a manual transmission synchronizer.

Additionally, you should bring your car in for routine gearbox maintenance. Bring it in for the suggested maintenance and as soon as you detect any transmission problems, such as the car moving or shifting differently, you should bring it in.

Bring your vehicle to a top-notch repair shop that will keep it operating great with routine transmission maintenance and other regular upkeep, such as that involving manual transmission synchronizers.

The Conclusion

High mileage, misuse, or improper maintenance can all lead to manual gearbox problems, but these are very uncommon. The synchronizers, which transfer engine power from the transmission to the wheels, are related items that frequently cause issues with manual transmissions rather than the transmission itself.

Gathering detailed information about the real problem is the key to diagnosing your manual transmission issue. You should get your car repaired as soon as you notice any symptoms of a broken manual transmission synchronizer.

A new synchronizer repair might be expensive, but it is crucial to keep a well-running car in good condition.

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”