Your vehicle is a complicated system of interconnected parts. As the saying goes, a machine is more likely to malfunction or fail if it has more parts.

Having said that, it can be a little amusing when these breakdowns do occur, though they shouldn’t be ignored. The transmission’s only function is to shift gears. What transpires, though, if your car won’t go into gear?

Sure, it’s better than, say, having your brakes fail and sending you careening into a tree. A non-shifting gearbox is still quite dangerous, though.

Imagine being on the road and discovering that you are suddenly unable to reach the often high speeds with other cars. Or perhaps you find yourself at a crosswalk and are suddenly unable to move or get out of the way.

Having a car won’t go into gear situations might get you into trouble in addition to being a pain in the behind. one where your ability to move quickly will be limited.

Additionally, you have no control over the direction the vehicle will go or are rendered utterly helpless. Furthermore, the fact that it has to do with your gearbox may need a costly repair. Is it difficult to fix a car that won’t go into gear problems, though?

When the Car Won’t Go Into Gear, What Do You Need to Do?

What should you do first and foremost if you find yourself in a circumstance where your car won’t go into gear right away? If you’re reading this while still driving, then gradually slow down and move to a safe side of the road where incoming vehicles cannot hit you. If you are still standing and have not moved at all, get out of your vehicle. If it’s obstructing traffic, you can also push it to the side of the road.

Car Transmission by Ritchyblack (FAL) A TCM, or transmission control module, is a component of contemporary vehicles that acts as the primary processing and reasoning center of the automated gearbox.

The most crucial thing to remember is that you need to immediately stop your vehicle! Also, refrain from using it until the transmission gremlin has been fixed. Even if you’re moving slowly and steadily, it’s not a good idea to keep driving your vehicle with a broken transmission. The problem you’re having is probably easily fixable. But placing extra pressure on it can make it worse.

Keep your car off for the time being, and let’s investigate why it won’t shift into gear. In many instances, you can quickly identify the problem and occasionally even troubleshoot it.

However, there will be times when the problem’s root is considerably deeper and necessitates a more complete investigation. It’s a good idea to have your vehicle towed to the closest shop in any case.

When your car won’t go into gear, the technician will start prodding around in the back to see what’s there. The underlying issues and potential remedies vary depending on the type of transmission you have.

In light of this, let’s examine the causes and appropriate fixes for situations in which your car won’t go into gear. Both automatic and manual gearboxes are covered in this guide, with the former being the first.

Why the Car Won’t Go Into Gear: Automatic Transmissions

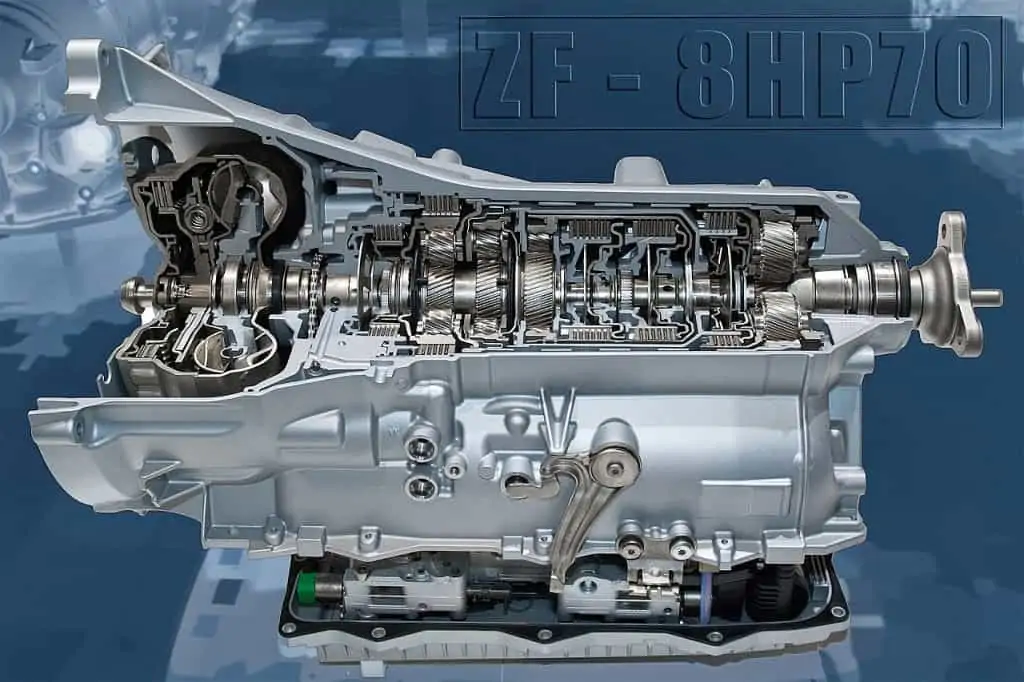

Since the 1940s, automatic gearboxes have been in use. These vehicles were more mechanically operated when they were at their peak. Its antiquated mechanism determined the engine load and your car’s speed using vacuum physics and the hydraulic pressure of the transmission fluids. However, the inner workings of automatics have changed over the last few decades to use more effective electrics.

A TCM, or transmission control module, is a modern automotive element that serves as the automated gearbox’s main processing and analyzing brain. The ECU, your car’s main computer, and many sensors around the transmission are then connected to it (or Engine Control Unit). By doing this, the gearbox can calculate the engine speed, rolling velocity, RPMs, and throttle position of your car.

The shift solenoid and valve body are then each provided an electronic signal. Together, they both manage the vital flow of pressurizing the fluids in the hydraulic transmission, which engages the proper gearing as needed. With this explanation of how cars operate, it should be clear that there may be problems in addition to mechanical ones. The electrics might also malfunction.

The most frequent reasons why the automatic gearbox in your car won’t go into gear are listed below.

1. ECU or TCM Not Functioning or Behaving Glitchy

As we just discussed, modern cars rely on electrical impulses to choose the appropriate gear. If they break down, symptoms like autos not shifting into gear may emerge.

Any malfunctions in this situation might affect the gearbox’s functionality and lead to further problems. For instance, your car won’t go into gear smoothly or may shift you into the incorrect gear.

The ECU or TCM of your vehicle is where the problem is located. Nevertheless, it’s also conceivable that some of the other devices might be flawed.

A broken car speed sensor, for example, or a bad throttle position sensor. For example, it can’t give the correct information to your car’s ECU and TCM if both of the latter break. As a result, the gearbox struggles to shift smoothly.

However, physical harm to the ECU and TCM modules might also be the root of this problem. Additionally, it’s possible that the ECU or TCM’s software and programming have been hijacked. This frequently occurs with brand-new vehicles that have recently made their market debut. Or, if your car’s computers had a significant software upgrade that interfered negatively with the gearbox.

Automatic transmission by Silverxxx / CC BY-SA 3.0. The pressure needed to activate the bands and clutches that decide what gear the vehicle should be in is provided by automatic transmission fluid.

Your local dealership or a transmission professional would likely be your only option for solving this issue. As long as they have the extra components on hand, most conventional workshops should be more than capable.

It is necessary to repair the sensors if the failing sensors are the root cause of the electrical issues keeping your vehicle from shifting.

Possible Fixes

The Throttle Position Sensor: The sensor alone would cost between $60 and $200, making it one of the more affordable solutions on this list. Throttle position sensors for the majority of cars typically cost around $100, while higher-end cars may cost you more. Additionally, labor costs are probably going to be modest, often about $100. You should budget between $150 and $400 for a complete replacement.

Vehicle Speed Sensor: Also known as the “transmission speed sensor,” this sensor may be replaced for a price comparable to that of a throttle position sensor. In certain cases, the sensor may only cost you $20, but for the majority of vehicles, you should prepare to pay between $50 and $150. Additionally, labor costs would often be about $100. For the majority of vehicles, replacement work will cost you between $130 and $300 overall.

Re-Flash (Reset) TCM – Your car won’t go into gear because of a small error in TCM’s software. In such a situation, you may either conduct a short update to get it working again or a complete hard reset of the module. The nearby dealer could carry out this for free if your car is covered by a recall or is still under warranty. Otherwise, a software reset will run you anything from $75 to $250.

Replacement of the TCM unit: This will inevitably be pricey, which is unfortunate. If you’re lucky, you could find refurbished TCMs for less than $150. A complete TCM kit typically ranges in price from $450 to $1,000. Additionally, depending on your vehicle, the extensive work needed might increase the cost by another $50 or even up to $400. In conclusion, a TCM replacement may cost you $500 or even $1,400.

2. A Low Amount, Dirty, Worn-Out, Or Old Transmission Fluid

Both manual and automatic vehicles have this problem. Within the gearbox, the hydraulic transmission fluids have a variety of functions. In terms of its similarities, the “gearbox oil” cools and lubricates the transmission. Therefore, its functionality is comparable to what motor oil does for the engine in your vehicle. However, automated gearbox operation depends on the transmission fluid.

In other words, without it, cars won’t function, which might explain why your car won’t go into gear. Gearbox oil, or more precisely “transmission fluid,” is a crucial component of your torque converter.

This separates the transmission from the engine during gearshifts, acting as the automatic version of a manual clutch. Only pressured fluid dynamics can make torque converters work.

Having said that, transmission fluids are not intended to last forever. The transmission will begin to fill up with innumerable microscopic pollutants over time, such as dirt and debris.

Alternately, all that time spent in the heat might burn the fluid out, making it less chemically adherent and less effective than it once was. Not to mention, there might be a fluid leak.

Possible Fixes

If this is the situation for you, mending it will be as easy as getting rid of the old transmission fluid. Then immediately swap it out for a new batch. It is advised that you perform this as part of your routine maintenance schedule.

Every two years, or around 30,000 miles, the fluid should be flushed and replaced in the majority of vehicles. Nevertheless, some professionals are content to assert a 100,000-mile gap.

Typical gear selector for an automatic transmission by Upior polnocy / CC BY 2.5. A minor bug in TCM’s software prevents your vehicle from putting itself into gear. You may either perform a quick update to get it operating again in this circumstance or a full hard reset of the module.

Therefore, to determine when a recommended fluid change is ideal for your specific car, consult the owner’s manual for your vehicle. An invoice for a flush and change job will typically cost between $150 and $250.

However, others could charge more than $400 for the same service. What if the transmission in your car was completely dry when the mechanic opened it up? If so, you need to deal with a leak.

Transmission fluid leaks can occur in a variety of locations, and their repair can be complicated or expensive depending on where it occurs. The following are some of the most typical locations for fluid leaks and the associated repair costs:

- $150 to $200 (or $20 if you only want a basic sealant) for a Fluid Pan Gasket

- $250 for a Fluid Pan Drain Plug Gasket.

- $100 to $500 (repair or rebuild kits are available for about $200) for Transmission Cooler Lines.

- $200 to $400 (a sealant, however, might cost as low as $20) for the Input/Output Shaft Seals

- $200 to $500 for the valve body

- $100 to $300 for a shift solenoid

- $600 to $1,100 for a torque converter

- $2000–$8000 (to the highest end in case the leakage is severe) for a Complete Transmission rebuild

3. You Can’t Change Gears Due to Shift Lock

You might come across something called a shift lock in a lot of the automatic-equipped vehicles on the road nowadays. The gearbox is locked in place by this device, which stops you from inadvertently shifting gears.

The shift lock often only releases itself when you simultaneously depress the brake pedal and hit the button on the gear lever. After that, you can shift as normal.

This will prevent you from accidentally shifting out of Park or Reverse. Both scenarios have the potential to result in fatalities and horrific catastrophes because rolling vehicles have happened in the past.

It serves as a crucial safety element and a safety net to avoid unintentional gear changes. For instance, putting your car in reverse while you’re driving will cause your transmission to fail quickly. Certainly considerable wear.

Possible Fixes

Sadly, there could be instances where the shift lock is broken. We typically blame the shift interlock solenoid for the problem. Some vehicles also feature electronic shift locks.

As a result, you cannot shift at all if your car’s battery is dead. Jump-starting the battery or replacing it entirely are your two options if you want to try to get it operating. Typically, a brand-new 12V battery will cost between $100 and $250.

Torque converter by BerndB~commonswiki / CC BY-SA 3.0. The brain of an automated gearbox is the torque converter. It is very important to pay attention when engaging and disengaging an automatic transmission. Any malfunctioning automatic gearbox will prevent your truck from moving.

If not, the shift interlock solenoid can be damaged. This unit will require a total replacement investment of between $180 and $220. The good news in this situation is that most cars, but not all, have a way to disable the shift lock. Typically, you have to insert your ignition key into a console slot. In an emergency, this is a terrific method to start your vehicle, but we still advise getting it replaced later.

4. Defective Torque Converter

Clutch mechanisms in manual gearboxes connect and disconnect the transmission from the engine. A torque converter in an automatic gearbox serves the same purpose.

The pump, stator, and turbine are the three main parts of the torque converter. Hard shifting may result from any of these parts failing. Keep in mind that a defective torque converter can also prohibit the gearbox from engaging in any gear while inquiring “what causes gears won’t engage.”

Possible Fixes

Torque converter replacement: The torque converter is the brain of an automatic gearbox. When engaging and disengaging an automatic transmission, is crucial. Your truck won’t move with any automatic transmission if it malfunctions.

Certainly, changing it will solve the issue. It may fail in a variety of ways, though. I advise you to read this in-depth essay on the signs of a failing torque converter as a result.

Why the Car Won’t Go Into Gear: Manual Transmissions

You must already be familiar with how manual functions. Instead of allowing the transmission to automatically move the gearing for you, every gear-changing motion is manually triggered. You need to depress the clutch pedal for it to work.

The clutch is compelled to disconnect the gearbox from the engine as a result. As we previously discussed, the torque converter performs the same function in automatic vehicles.

The gear lever must then be manually moved into the desired gear ratio while your foot is still on the clutch pedal. Afterward, and after selecting a gear, you can depress the clutch pedal to keep driving in that gear.

The forward driving gears, as well as Neutral and Reverse, are all changed using this procedure. Park is not listed in a handbook.

Due to their involvement, manuals are preferred over automatics by the majority of aficionados. However, a sizable majority would much rather have an automatic. Mechanical linkages, which are necessary for the manual gearbox to function, are where the problems exist.

Given that manual gearboxes are largely mechanical, you won’t discover electrical gremlins to be the main culprit.

Here are some of the most common explanations for why your car won’t go into gear when you have a manual gearbox:

1. A Clutch That Is Outdated or Burned Out

Since the clutch pedal and real clutch have a direct relationship with manual autos, any problems are simple to identify. If the pedal feels a little bit too stiff, you may immediately sense the signs of a worn-out or damaged clutch.

You can also notice unpleasant grinding or crunching noises coming from the gearbox when shifting gears. Or perhaps you’ll detect the heaty, faint perfume of a clutch that has burned out.

Push-button gear selector by Comyu / CC BY-SA 3.0. With an automatic gearbox, the driver only needs to pick D on the shifter to complete all the work. Using fluid pressure, the vehicle independently completes gear shifts.

Whatever the case, the clutch is one of the most crucial components of any manual-geared vehicle. It is important to note that the clutch is a system made up of several pieces. These include the pressure plates, throw-out bearings, and the primary clutch disc.

You may also include the flywheel in your calculations. The flywheel is responsible for balancing the gearbox and engine connection.

Despite being essential to your car’s performance, the clutch is susceptible to wearing down or burning out and fails over time. The type of vehicle a clutch powers and how carefully you use it to determine how long it will survive.

Some clutches degrade after 30,000 miles or less. However, most vehicles go over 150,000 miles before needing significant reconditioning or replacement.

Possible Fixes

A technician should be able to tell whether the clutch requires a substantial repair because it is frequently changed equipment. Most vehicles will cost between $450 and $650 on average for a replacement clutch, including labor.

However, if your vehicle is difficult to work on and needs a specialty, performance, or heavy-duty clutch, the repair expense might go up to $750 or more.

Additionally, because the clutch is made up of multiple pieces, replacing each one comes at a different cost.

- $300 for a clutch kit (this contains the clutch disc, the throw-out bearings, as well as pressure plate)

- $500 for the flywheel (this is for a complete replacement, not refinishing, which may be as low as $50)

- $100 to $300 for hydraulic pumps (these pumps are specifically designed for hydraulic clutches)

2. Gear Synchronizers That are Defective or Worn Out

Since you have to tip-toe with the engine rpm on older vehicles, smooth gear changes will never be easy. The transmission must be precisely activated to prevent jerking or grinding since the engine speed can reach thousands of revolutions per minute (RPM). The only option left is to precisely time and match your gear changes with the RPMs. Fortunately, contemporary vehicles are superior.

They contain a feature to facilitate smoother and simpler gear changes called a gear mesh synchronizer, sometimes known as “synchros.”

It changes into gear per your high engine speeds, as its name suggests, and synchronizes the gearing. Unfortunately, these synchros may degrade as they become older. They typically age prematurely as a result of violent or aggressive moving.

Possible Fixes

Given that accessing the synchronization necessitates disassembling the gearbox, a replacement will be quite expensive. Parts are reasonably priced, costing between $200 and $400 for a set of synchronizers.

If not for the labor costs, this isn’t that awful. The gearbox might need days to gently open up and disassemble. Before installing the new synchronizers and putting everything back together, that is.

The extensive labor will often set you back between $600 and $1,400. This should mostly rely on how simple it is to access the synchronizers in your specific car.

Paddle shifter by Michael Sheehan / CC BY 2.0. Your vehicle won’t shift into gear? It might very well be that there’s an issue with the actual shift linkage or gear shifter. This issue affects both manuals and the majority of automatics now on the market.

Additionally, we should point out that your vehicle has many synchronizers. There is typically one synchronizer for every gear ratio. A 5-speed manual transmission will thus have 5 distinct synchronizers, each at a different price.

The first gear synchronizer will fall between the $200 to $400 range. The cost is often the same for the second, third, fourth, fifth, and so forth. So don’t be shocked if the cost of replacing the synchronizers comes to $2,000 or more.

However, if the other synchronizers are in good shape, you can replace simply one or a couple of them. Having said that, rebuilding or replacing the complete gearbox is undoubtedly more expensive than simply replacing the damaged synchros.

3. Transmission Shift Linkages are Broken

Last but not least, a problem with the actual shift linkage or gear shifter may easily be the reason why your car won’t go into gear. Both manuals and the majority of automatics on the market today have this problem.

In manual-transmission vehicles, you could notice this when the clutch pedal gradually sinks to the floor. Whatever the case, we could readily blame the transmission shift cable.

In contrast to an automatic, which only has one shift cable, manuals frequently have two. These cables may eventually stop working as a result of extreme wear or strain. This problem affects manuals more frequently than automatics.

Consequently, they typically survive between 125,000 and 175,000 kilometers. In addition, it’s possible that the shift cable was loosened when driving over extremely rough terrain or after an accident.

Unexpectedly, repairing this seemingly simple wire may be extremely expensive. Parts may be purchased for roughly $120 or so. However, because obtaining the cable may be somewhat challenging, labor costs typically surpass the cable itself.

All things considered, anticipate an automated shift cable replacement to cost between $250 and $350. The price increases to between $200 and $450 for manual shift cables due to their increased complexity.

Car Won’t Go Into Gear: The Automatic Vs. The Manual Transmissions

Automatic Transmission: With an automatic transmission, all the hard work is done for the driver by merely selecting D on the shifter. The car autonomously completes gear shifts on its own using fluid pressure. The planetary gear set is the automatic transmission’s brain. The various gear ratios that the gearbox utilizes are produced by this component.

Automatic transmission fluid provides the pressure required to engage the bands and clutches that determine what gear the car should be in. This fluid aids in propulsion in addition to cooling and lubricating the transmission’s working components.

The powertrain is connected to a torque converter, which functions like a clutch on a manual transmission. Planetary gears are locked and unlocked using fluid to change gear ratios. There is no action required on the part of the driver for this automated shifting.

Manual Transmission: When a vehicle has a manual transmission, the driver shifts the gears manually as they accelerate and decelerate the car. The shift lever, which is situated on the center console, is linked to the transmission via a linkage.

Using a manual transmission also necessitates using the clutch pedal, which is situated to the left of the brake pedal. The clutch mechanism, which is situated between the engine and the gearbox, disengages when the clutch pedal is pressed.

Internals of a manual transmission by Series8217. With a manual gearbox, the driver must manually change gears as they accelerate and decelerate the vehicle. A linkage connects the transmission to the shift lever, which is located on the center console.

To change gears, you must depress the clutch pedal to stop the transmission from receiving power from the engine.

The driver depresses the clutch pedal to select a different gear, pushes the shifter to the new gear, and then releases the clutch pedal to re-engage the engine’s power with the transmission.

It takes some work to learn to drive a stick. If the clutch pedal is depressed too quickly, the engine will stall; if depressed too slowly, it may result in premature wear.

The Conclusion

This wraps up the examination of the typical reasons why your car won’t go into gear, along with the associated repairs and expenses. In general, a variety of problems might cause an inability to shift into gear.

These may be as straightforward as software errors in your ECU or TCM that may be resolved with a hard reset. Worst case scenario, a mechanic may need to open your transmission.

The range in difficulty and cost of resolving this problem is obvious. It may easily rise from a few dollars to several thousand if essential internal parts need to be replaced, starting at only a few.

However, it supports the argument that getting this problem identified as soon as feasible is much preferable to ignoring it. Resolving the issue afterward will just make it worse and cost more money.

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”