Because a bad distributor might mess with the ignition, your engine will run less efficiently. Since the distributor is a crucial component of the ignition, any problems with it could harm your car.

When we examine bad distributor symptoms, we find that they can cause serious issues like rough idling, shaking, and even stopping.

There are numerous causes for a distributor to experience issues. Among the most frequent causes are wear and tear over time. Because of its hostile surroundings, the distributor is also prone to developing issues.

However, it is vital that you first comprehend how a distributor functions before we dig further into bad distributor symptoms.

A Car Distributor: What Is It?

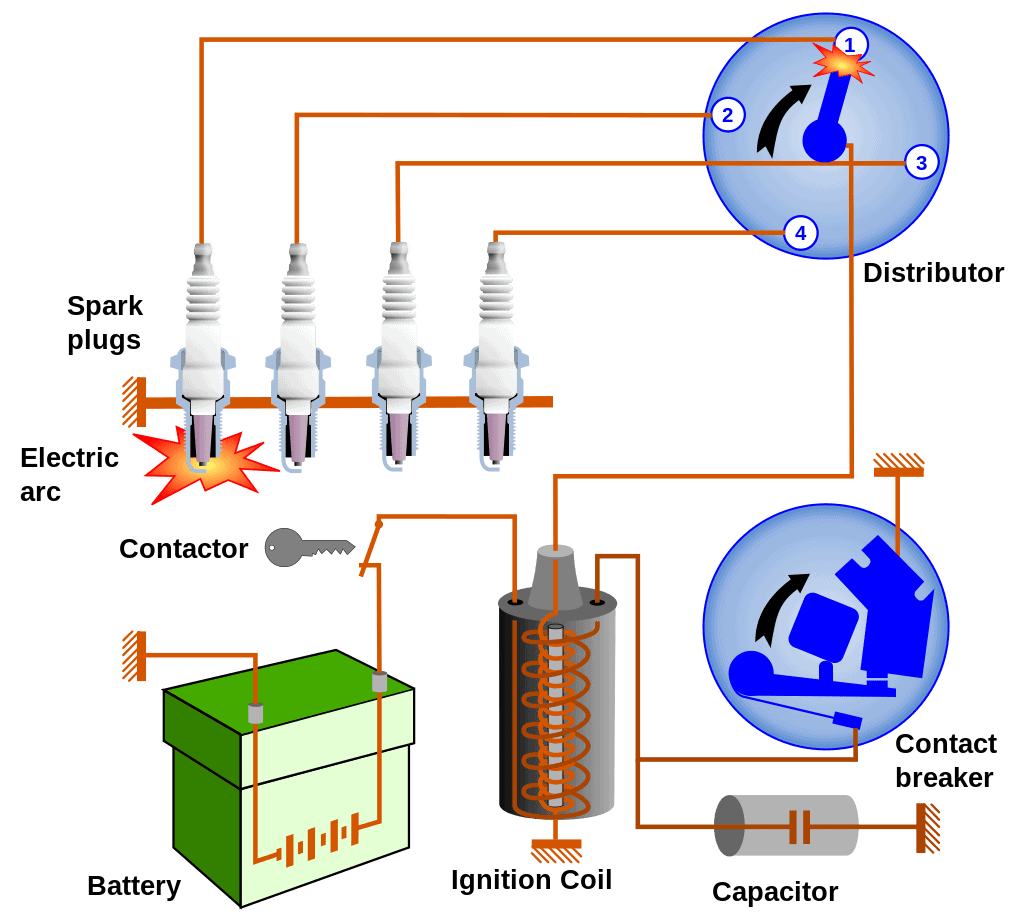

In cars with mechanically timed ignition, a distributor is simply a revolving switch.

The distributor has two primary functions. The distributor’s initial and most important job is to distribute a high-voltage current in the proper firing order from the ignition coil to the engine’s spark plugs.

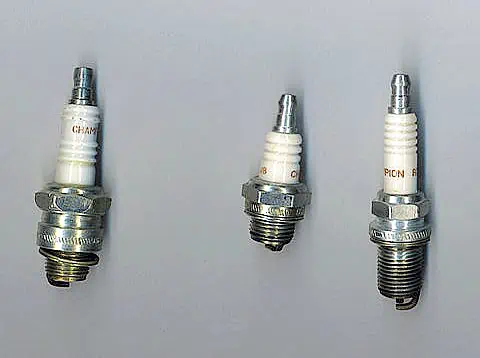

The distributor, as its name suggests, sends electrical impulses to the spark plugs so they can produce the spark required for ignition and internal combustion engine operation.

Controlling the circuit of the ignition coil is the distributor’s secondary function.

Some engines additionally have an oil pump that is managed by the distributor.

Electronic ignition systems that are “distributorless” have taken the place of distributors in modern automobiles. These systems either use coil packs with several connections or individual ignition coils mounted on top of the spark plugs in vehicles.

In these cars, the engine control unit (ECU) delivers signals to the ignition coils after detecting the crankshaft’s position.

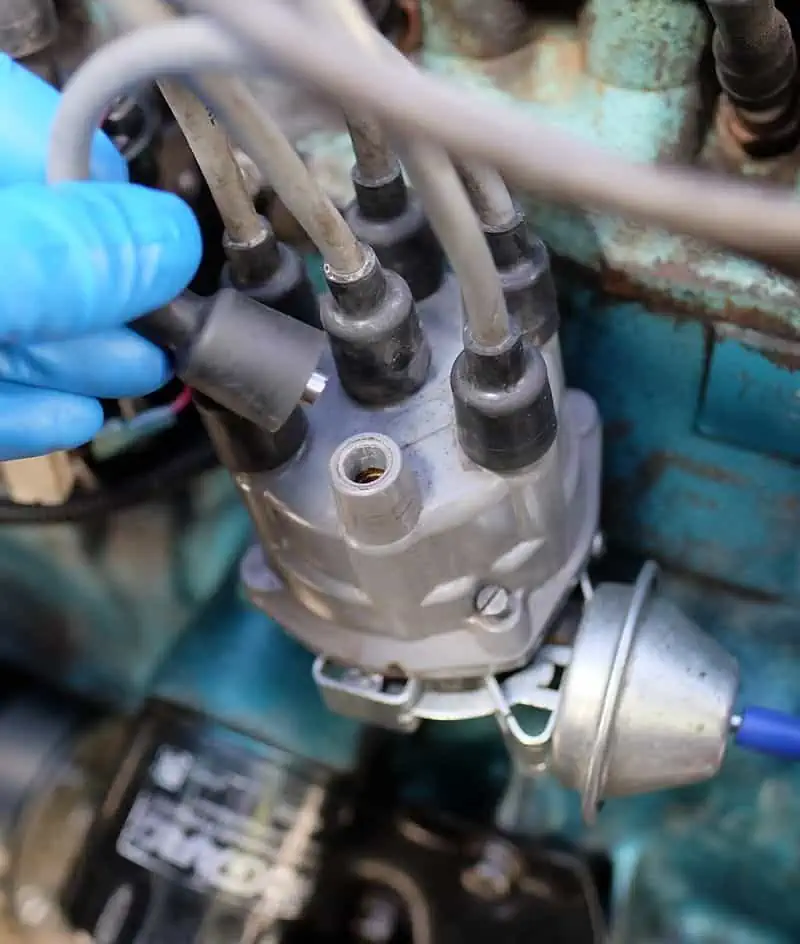

Top of the distributor with wires and terminals by Dennis Bratland / CC BY-SA 4.0. The distributor performs two main tasks. The ignition coil sends a high-voltage current to the spark plugs in the engine, and this is the distributor’s first and most crucial task.

Where Can You Find the Distributor Cap In a Car?

Underneath the car’s hood is where you’ll find the distributor cap. Locate a piece of grey plastic towards the center of the engine by opening the hood. Black cables that link the spokes on the distributor cap’s top give it the appearance of a crown. The spark plug wires that power the engine of your car are housed in these substantial black cables.

How Does a Distributor Function In a Car?

The ignition process depends heavily on the distributor. It delivers high voltage at the proper time and in the correct firing order from the secondary coil to the appropriate spark plugs. When examined closely, the distributor performs a variety of duties. The distributor cap and rotor handle the initial job.

The suitable cylinders receive a high-voltage transmission from the coil. The distributor rotor, which contentedly rests on the distributor cap, is connected to the secondary coil. A spring-loaded brush connects the ignition coil to the rotor. The rotor is turned by the engine’s electric current.

The rotor transfers high voltage as it spins to several contacts without making any physical contact. The spark plug wire carries the high-voltage pulses, which are then sent to the appropriate cylinder.

To get the best engine performance and efficiency, this precision is essential.

This arcing eventually wears down the rotor and cap. For this reason, when you perform a tune-up, they are both replaced. Along with the distributor, the spark plug wires can deteriorate and lead to some highly enigmatic engine problems.

If you drive an earlier model automobile, the distributor can be different. With these earlier engines, distributors with breaker points were standard equipment.

Spark plugs won’t receive the required spark if any distributor component malfunctions. As a result, the fuel mixture won’t be able to ignite using spark plugs.

This will consequently have an impact on how effectively the engine in your car distributes power. A car’s starting trouble and a slew of other performance problems are caused by a malfunctioning distributor.

Which are the Most Common Bad Distributor Symptoms?

As you are now aware, even though the distributor is a minor component, it is essential to the operation of a car. You wouldn’t want to own a car with distributor issues, that much is certain.

But even when you’re driving, these issues can arise. Therefore, you must develop the ability to recognize a defective distributor before the issue gets worse. Eight of the most typical bad distributor symptoms are listed here.

1. Difficulty Starting the Car

Your automobile might not start if the distributor cap is not securely fastened or is not operating as it should. This occurs as a result of the absence of the crucial spark required for combustion. The engine won’t operate if the spark plugs aren’t receiving it. In addition to the cap, a damaged rotor or shaft might also make it difficult for your automobile to start.

This is especially clear during the colder months when the majority of beginning issues appear. The components of the distributor freeze in cold weather. When you try to start the car, the sudden heat surge causes the distributor cap to crack.

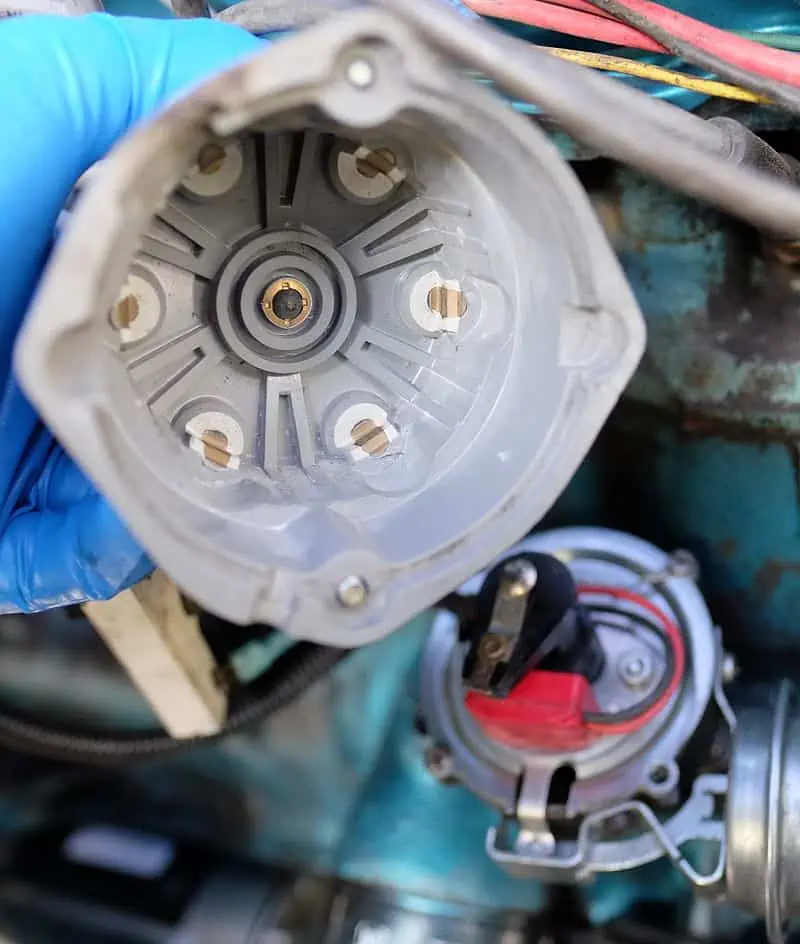

Rotor contacts inside the distributor cap by Dennis Bratland / CC BY-SA 4.0. The secondary coil is attached to the distributor rotor, which is contentedly resting on the distributor cap. The ignition coil is connected to the rotor by a spring-loaded brush. The electric current from the engine rotates the rotor.

Breakage will eventually result from the cracks. Cars parked outside are particularly prone to this situation. Cars that are parked in cold, unheated garages are also more prone to starting issues.

2. Misfires In the Engine

Yes, a variety of engine issues can cause misfires. However, one of the most frequent causes of engine misfires is a defective distributor. The distributor is the first place to look if your engine misfires, as this is the most secure area to start.

Check the distributor rotor and the cap assiduously for any cracks. An engine misfire typically indicates that the rotor and cap need to be replaced.

It sounds like an engine is stumbling when it misfires. When the distributor cap is unable to provide the spark plugs with enough electricity, misfiring happens. Any fault in the cap’s components will be sensed in the engine’s performance because it controls the engine’s firing order.

3. Abnormal Shaking

An old-fashioned sign of a failed distributor is unexplained shaking while the engine is running. This could be anything from a slight trembling to a shaking that is more strong and more pervasive throughout the vehicle.

A distributor rotor that is not spinning properly could be the root of the problem. Additionally, the cap may shake if the voltage is not adequately supplied during the right cylinder’s power stroke.

The vehicle shakes erratically when anything interferes with the cylinders’ firing and timing mechanisms.

The most likely cause of your car shaking while idling or stopping is a bad distributor, according to you. When changing gears or starting the car, the shaking could be particularly noticeable.

4. The Car Stalls and Backfires

Another red flag is that your automobile has a damaged distributor that is backfiring from the exhaust or stalling while coasting. When the engine loses power as a result of incorrect combustion, the car backfires or stalls.

You most likely have a failed distributor if your automobile stops out shortly after starting the engine.

As was already mentioned, for internal combustion to take place, the cap needs to supply the spark plugs with enough voltage. Engine performance will be reduced if the rotor is not rotating properly.

The rotor can become improperly spinning due to a crack in the cap or a blockage in the distributor. A backfiring issue or stalling could happen from this.

5. Strong Squealing Sounds

High-pitched noises coming from the bearings inside the distributor are another typical sign that it is broken. Usually, when you start the engine, you’ll hear a squealing sound.

The distinctive squealing sound that a faulty distributor makes it simple to identify it from other engine noises. Look under the distributor cap if you hear this type of noise coming from the engine compartment.

Car ignition system. The upper right is the Distributor by Frédéric MICHEL / CC BY-SA 3.0. The distributor plays a key role in the ignition process. It sends high voltage from the secondary coil to the relevant spark plugs in the proper timing and firing order.

When a distributor gets caked with grease and other impurities, it typically makes a screaming sound. These accumulations obstruct the airflow, which results in a high-pitched sound.

It’s necessary to take your car to the mechanic for a more complete inspection if the yelling sound continues despite a thorough cleaning of the cap.

6. Trouble Turning Over

You might notice that the vehicle is having trouble starting in addition to the engine stalling. When it’s cold, the engine frequently struggles to start, and when it’s hot, it rarely does.

The battery provides power to the spark plugs when you turn the ignition key. The initial combustion is caused by the spark that results.

The crankshaft is turned by the initial combustion energy, which also propels the vehicle forward. Lack of turning over, which is the crankshaft’s motion, indicates problems with a broken distributor.

The majority of the time, a broken cap is at blame in situations like this. If the cap is intact, the crankshaft or timing belt may be the source of the issue.

7. The Check Engine Light Illuminates

An incorrect combustion process will be detected by the engine control unit (ECU), which will then turn on the check engine light. One of the typical causes of incorrect combustion is a defective distributor rotor or cover.

If the distributor is not transferring voltage consistently or correctly, the check engine light will turn on.

A clogged rotor and a cracked or broken cap are two of the main causes of incorrect combustion. If the ECU identifies even the smallest instance of improper timing or firing order, the check engine light illuminates. Of course, there are a lot of additional mistakes that might set off the check engine light.

The check engine light and other warning indications of a defective distributor, however, should prompt you to examine your distributor. The majority of automobiles using distributors were likely built before the ECU era. As a result, finding distributor faults cannot be done by simply reading error codes.

8. Fluctuating RPMs

Another obvious sign of a poor distributor is irregular RPMs. Check the distributor rotor and cap if you suspect that your RPMs are off.

Your inconsistent RPMs could potentially be due to faulty distributor wires. The distributor feeds the cylinders erratic current if the cables are broken.

Examine the distributor rotor for correct rotation and the cap for signs of burns, cracks, or corrosion. Check each distributor wire if they appear to be operating without a hitch.

How Can I Diagnose Bad Distributor Symptoms?

If your vehicle displays any of the aforementioned bad distributor symptoms, then your distributor is malfunctioning.

However, the aforementioned signs, such as engine misfires and illuminated check engine lights, might be brought on by a variety of other issues. Similar symptoms can also be present in issues with the engine and ignition system.

A typical car engine by Yones / CC BY-SA 3.0. Misfires can result from a wide range of engine problems. However, a faulty distributor is one of the most typical reasons why engines misfire. If your engine misfires, start by inspecting the distributor because it is the safest place to start.

You must thus examine and test your distributor to determine the precise problem your automobile is experiencing.

If ignored, bad distributor symptoms might swiftly develop into an engine issue. If the vehicle exhibits any indications of a defective distributor, it should be examined to prevent further engine issues.

Resources Required to Test Bad Distributor Symptoms

- The Ratchet

- The Ratchet Socket

- The magnet Screwdriver

- A spark plug

- A Tester for light or sparks

- A voltmeter or a multimeter

- A source of light

Step 1: Examine the Distributor Cap

The most frequent cause of distributor issues is the distributor cap. Therefore, if you think you may be experiencing bad distributor symptoms, you should go there first.

The sparks are produced by the distributor caps, as was stated before in this text. Consequently, sparks that properly arc should be produced by a functioning distributor cap. The cap’s surface should be clean of any debris or grease.

Use your racket and socket to remove the distributor cap after that. This should make it easier for you to carefully inspect it for signs of damage.

Any indications of rust, erosion, or corrosion should be investigated because they could be the root of your distributor issues. Look for any burns or traces of carbon throughout the whole cap, including the cap rotor.

The issue might exist if there are carbon traces in the distributor cap. Carbon traces might cause a misfired spark between the plugs and make the distributor malfunction. Typically, the misfired spark results in a broken electric connection.

Step 2: Examine the Contact Points

The contact points will then be examined for issues if the distributor caps are in excellent shape. Nevertheless, you ought to examine the contact points only after examining the condenser.

A broken wire lead could be the cause of the condenser being broken or unsealed. This results in arcing, which can seriously harm the engine.

Checking the contact points comes next after making sure the condenser is operating properly. Contact damage can cause a variety of ignition issues.

Keep an eye out for any indications of deterioration, corrosion, or other damage. Consider replacing them if they appear scorched.

Step 3: Diagnose the Arcing

You must put the spark plug wires through a test for this step. To check the arc of your distributor, use a spark tester.

Different sizes of automotive spark plugs by Gzuckier / CC BY-SA 3.0. The spark plugs receive electrical impulses from the distributor, as suggested by its name, for them to generate the spark necessary for ignition and internal combustion engine operation.

You can do this by sparking the ignition while the spark tester is inserted into the metal portion of the plug wire. That is not the issue because the tester will show a spark sign if the arc is firing.

Use a test light to check the coil if the spark tester does not show any sparks. Fire the ignition while attaching the test light to the coil’s side.

If the device emits any light flashes, the coil is malfunctioning. If there are no flashes or sparks, your ignition system’s electrical wiring may be the source of the issue.

You have a defective coil if the spark tester operates with the coil connected to the positive terminal. If both terminals are powered, there is a problem with the contact points.

If both the positive and negative sides function, however, it suggests the ignition wiring has to be checked out more thoroughly.

How Can I Fix Bad Distributor Symptoms?

What can be done to stop further harm to the engine now that you have determined that you are dealing with a malfunctioning distributor? The type of distributor issue you are having will dictate your next plan of action. These are some of the distributor fixes you can use.

1. Fixing a Distributor Cap Containing a Crack

To lessen harsh idling, a damaged distributor cap should be changed right away. You should routinely check the distributor cap for any indications of problems to prevent cracking. Avoid leaving your car parked outside during colder months whenever possible. As much as you can, try to protect your car from freezing weather.

2. Fixing Dirty or Corroded Distributor Cap

The terminals of the distributor cap may corrode as a result of water vapor condensation in the distributor cap. From the crankcase, this water vapor enters through the distributor shaft.

Upon engine cooling, the water vapor turns into liquid. Corrosion is created when water interacts with the metallic components of the distributor contacts.

The distributor’s other main source of moisture is the battery. The battery creates acid when it is overcharged by the alternator, which collects inside the distributor.

The distributor may become damp if the plug wires’ insulating shell becomes trapped wet if the plug wires are porous.

The distributor cap is prone to accumulating filth and debris in addition to dampness. With the help of a multipurpose cleaner like WD40, grime and dirt accumulations can be readily removed.

If you find a rusted or clogged distributor cap, clean it to make it work again. If the distributor cap appears to be loose, replace the cap gasket.

Following are some cleaning instructions for distributor caps that are rusted or dirty.

1. Disconnect the Spark Plug Cables

Label the cables if they aren’t already so you can reorder them if necessary. Pull them out of the distributor cap terminals after marking them.

2. Take Off the Distributor Cap

Unscrew the cap with a screwdriver, then carefully raise it. Two screws are typically used on each side to secure the distributor cap to the distributor.

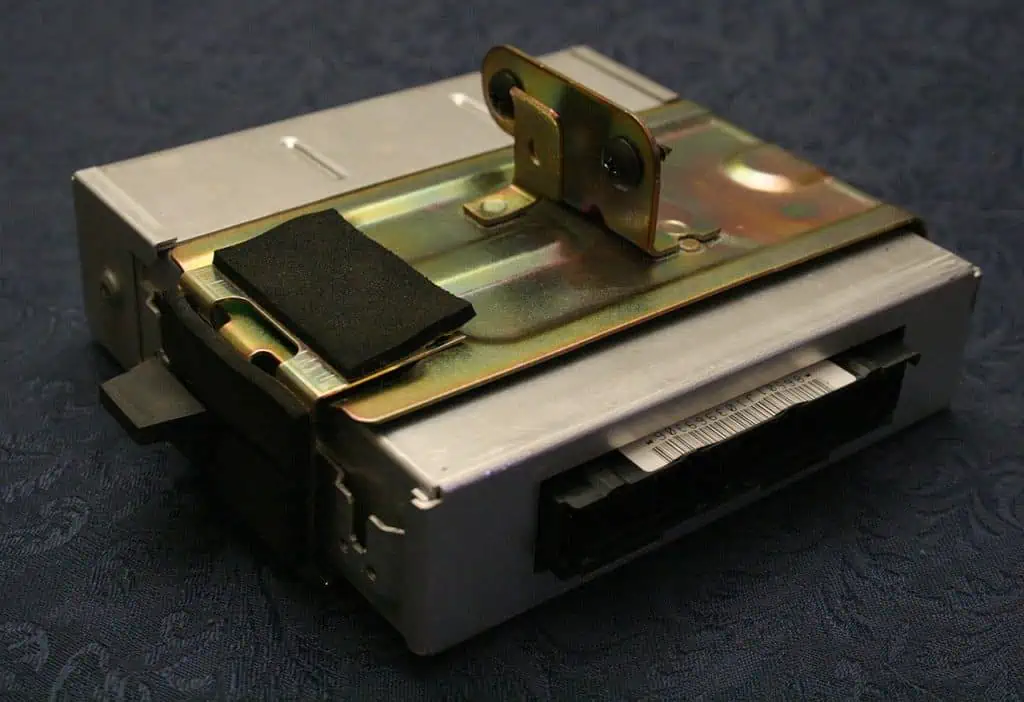

An electronic control unit (ECU) by Specious / CC BY-SA 3.0. The majority of vehicles that use distributors were probably created before the advent of ECUs. As a result, reading error codes alone is not sufficient to identify distributor issues.

3. Clean Up the Connection Points

Once the distributor’s metal contacts have been exposed, clean them with a soft-bristle brush and contact cleaner. The brush needs to be sufficiently rough and soft to remove any carbon buildup or oxidation layer from the metal terminals. Don’t forget to WD40-spray the interior metal connections.

4. Dry the Cleaned Cap

Use a source of compressed air, if available, to dry the cleaned cap. Compressed air will hasten the drying process and remove any residual particles. To dry the distributor cap, you could alternatively use a new rug.

5. Assemble Everything Once Again

Apply the entire method again in reverse. Reinstall the cap, then tighten the screws on the sides. If the gasket is worn out, moisture may enter the cap and lead to other issues. If required, change it.

Apply a little silicone seal around the base of the cap for further protection. The spark plug wires should be connected according to the labeled order. Check to determine if the remedy worked by starting your engine.

Distributor Cap and Rotor Replacement

It is advised to think about replacing the distributor cap and rotor if you have tried the aforementioned treatments and are still having issues with your distributor. The price to replace it will change based on the brand and model of your car.

A new distributor assembly will typically cost you between $250 and $500, and labor will often cost you between $75 and $150.

As replaceable maintenance items, distributors are not covered by insurance when they need to be replaced. However, if the distributor is harmed in a covered accident, your insurance policy might cover the repairs.

Can I Change the Distributor Cap and Rotor On My Own?

Most car enthusiasts and anyone with a basic understanding of automobiles can save money by replacing the part yourself. There are no complicated instruments needed for this. All you need to complete the job is a good repair manual, a ratchet, a ratchet socket, and a screwdriver.

Just be sure to take the required safety procedures, such as removing the batteries from the automobile, to avoid electrocuting yourself.

At What Intervals Should I Replace the Distributor Cap and Rotor?

Due to the high voltage they frequently encounter, the distributor cap and rotor are particularly prone to wear and strain. High voltage passes through your distributor each time you start your engine.

Therefore, they will inevitably become worn out with time. Following the replacement of the distributor parts, the ignition system should be carefully inspected as well.

When performing routine maintenance, make sure the ignition system is properly inspected to detect distributor failure. However, the longevity of the distributor cap will depend on where you park your car throughout the winter.

If you continue to drive through heavy puddles, the distributor may also fail. The likelihood of moisture entering the distributor cap rises as a result.

For the majority of automobiles, routine maintenance is advised every 25000 miles. Most service centers frequently replace the distributor cap and rotor regardless of how they currently look.

The cap and rotor should be changed every two years if your automobile isn’t used much, even if they don’t exhibit any bad distributor symptoms.

A check engine light or malfunction indicator lamp (MIL) by Wikiuser100000 / CC BY-SA 3.0. The engine control unit (ECU) will identify a flawed combustion process and activate the check engine light as a result. A damaged distributor rotor or cover is one of the common reasons for improper combustion.

Why Does a Distributor Cap Corrosion Occur?

Corrosion on the distributor cap is one of the main causes of difficulties with the cap. The cap on your distributor may have an odd buildup when you go to clean it.

Either corrosion on the distributor cap or dirt on the ends of each spark plug wire terminal could be the cause of this. The corrosiveness of your distributor cap may be caused by several factors.

Moisture and humidity are the primary causes of any corrosion on the distributor cap. As it rises into the distributor shaft, moisture and water vapor from the crankcase may eventually gather inside the cap.

When your car’s engine cools down after you’ve driven it, the water vapor condenses and may interact with the metal contacts, leading to rust.

The second cause of corrosion on the distributor cap is an overcharge of the battery system by the vehicle’s alternator. This may then result in the production of battery acid, which can accumulate inside the distributor cap and lead to corrosion.

Third, the distributor cap could become wet if the wires are porous and allow water to enter. Corrosion could result from this as well. Your car’s distributor cap gasket needs to be replaced if you find a loose one to stop corrosion.

How Do I Protect the Distributor Cap from Getting Moisturised?

After checking your distributor cap, if you see that it is gathering damp, something is amiss. If you don’t solve the issue, your car can develop more serious problems.

Mark the spark plug cables before disassembling the distributor cap to clean it out. When you’re done cleaning it, this will guarantee that the distributor is put together properly.

To clean out dirt and debris from the distributor cap, always use a fresh, dry rag. After that, leave it somewhere warm and dry to finish drying. Make use of compressed air to hasten the drying process.

Additionally, you ought to replace the distributor cap seal regularly with a new one. Applying a silicon seal around the distributor cap’s base will give an extra layer of protection and keep moisture and water droplets out.

How to Prevent Distributor Issues

To prevent unneeded troubles, it’s crucial to take appropriate care of your car. To make sure the engine is adequately lubricated, you should routinely have your vehicle’s oil changed.

Additionally, it’s crucial to pay special attention to your car’s distributor cap. This is typically the main cause of an engine failure in its entirety. Distributor damage may result from erosion and excessive buildup. For this reason, you ought to clean the cap frequently.

The Conclusion

The ignition system wouldn’t work without the distributor. It is essential to the functionality of your car. Undoubtedly, you wouldn’t want a poor distributor in your car.

The entire vehicle is rendered useless and incredibly inefficient by a damaged distributor. Therefore, it is vital to be able to identify bad distributor symptoms before they progress to an engine problem.

If your car’s distributor does break down, it is not the end of the world, though.

Fortunately, a bad distributor is easily fixable or replaceable with the aid of a few straightforward tools. However, some distributor issues could need the help of an experienced mechanic.

Top of the distributor with wires and terminals by Dennis Bratland / CC BY-SA 4.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”