The gearbox’s input shaft and crankshaft rotate at various rates when the clutch is disengaged. This variation might occur thanks to the pilot bearing.

The pilot bearing has to be changed as soon as possible if you hear a whistle or other odd sounds when you depress the clutch pedal.

You will learn more about the pilot bearing in this post, as well as how to use a tool to remove the pilot bearing. Additionally, you will learn the signs of a failing pilot bearing or bushing and how to fix it.

A Pilot Bearing: What Is It In a Car?

The pilot bearing serves one main purpose. It offers a point of support with less friction at the gearbox input shaft’s end. Essentially, there are three different types of pilot bearings:

- The needle bearings.

- The roller bearing model or the conventional ball bearings (the sealed bearing model)

- The sintered bronze bushings (they look more like the bronze sleeve and are found on much older cars)

The two most popular types of bearings are needle bearings and bronze bushings.

In manual gearboxes, the input shaft of the transmission and the crankshaft of the engine rotates at various rates. This is made feasible by the pilot bearing.

Most rear-wheel-drive cars with manual transmissions will feature pilot bearings. Pilot bearings are also present in certain front-wheel-drive vehicles with manual gearboxes.

Car Transmission by Ritchyblack / FAL. A worn pilot bearing will ultimately cause the gearbox to completely disengage if it is not replaced. Since the input shaft and gears will be separated, it will essentially lock up.

How Do Pilot Bearings Function In a Car?

The pilot bearing, which supports the opposing end of the transmission’s input shaft and is a crucial component of how the clutch functions, is situated at the end of the engine’s crankshaft. With the aid of this bearing, the input shaft may be stopped and the gears of the vehicle changed.

Due to the shorter bell housing and the fact that the input shaft may be sustained within the gearbox without the additional assistance of the pilot bearing, certain front-wheel drive vehicles may not feature this bearing.

Where Is the Pilot Bearing Located In a Car?

The pilot bearing is located in a hole at the end of the car’s crankshaft flange because it is directly linked with the gearbox input shaft.

Why Do Pilot Bearings Go Bad?

The self-lubricating pilot bearing occasionally runs out of lubricant. This prevents the clutch from disengaging by preventing the input shaft of the transmission from stopping rotating.

When this occurs, the needle rollers inside the bearing will separate, enabling the input shaft and clutch disc to wander inside the pressure plate and flywheel.

Which are the Common Bad Pilot Bearing Symptoms In Cars?

Similar to other auto parts, the symptoms may change according to the brand and model of the car in question. However, the signs and symptoms are typically the same.

1. Abnormal Noise from the Clutch

The loud whining sound made when the clutch pedal is fully withdrawn is a fairly typical sign of a faulty pilot bearing that anybody may notice. The severity of the pilot bearing’s deterioration determines how loud the rattling or grinding noise is.

Sometimes the noise won’t be coming from the pilot bearing; instead, it can be a problem with the gearbox or the entire clutch system. To distinguish between them requires expert diagnostic abilities.

2. An Unusual Feeling on the Clutch Pedal

Changes in the feel of the clutch pedal are another relatively simple sign. The pilot bearing condition impacts whether the clutch feels stiff or soft. The rigidity of the clutch pedal rises as a faulty pilot bearing progresses.

It will get difficult to depress the clutch pedal as the pilot bearing ages. It won’t be feasible to depress the clutch pedal at a late time to disconnect the gearbox.

Car crankshaft by Alex Kovach / CC BY 2.0. At the end of the engine’s crankshaft, there is a pilot bearing that supports the opposite end of the transmission’s input shaft and is essential to the clutch’s operation. This bearing allows the vehicle’s gears to be changed while the input shaft is halted.

3. Shifting Between Gears Becomes Difficult

The clutch kit’s purpose is to completely disconnect the gearbox from the engine. Therefore, the clutch kit has a difficult time performing its function entirely and effectively if any of its pieces develop defects.

You start having trouble changing gears, you start hearing grinding noises as you place the shifter on the gears, or the shifter pops up while you’re driving and shifts into neutral by itself. If you notice any of these symptoms, you should have the clutch kit, especially the pilot bearing, examined.

4. The Clutch Pedal Produces Abnormal Vibrations

When the driver shifts gears, the clutch pedal vibrates, which is another clear sign of a faulty pilot bearing. The clutch depresses smoothly and steadily when the pilot bearing is functioning properly.

However, if the clutch pedal begins to vibrate, it may be a sign of a worn-out bearing. When shifting gears and pushing the clutch pedal, these sensations occur. The pilot bearing’s inability to align with the transmission’s pressure plate causes the two to occur.

5. Poppings In the Transmission

The pilot bearing not only permits unrestricted movement but also eliminates vibrations, keeping the input shaft of the transmission steady and secure.

The input shaft might shift about because of a bad pilot bearing. Such movement throws the synchronizers and gears out of alignment and is in opposition to the transmission’s exact operation.

The transmission will jump out of gear if the gears and synchronizers are out of alignment. The gears, input shaft, and possibly the entire gearbox may eventually disengage as a result of this.

6. Complete Transmission Failure

You won’t miss this one even if you miss any of the set early symptoms of a bad pilot bearing. If a worn pilot bearing is not replaced, the transmission will eventually become entirely disengaged. In essence, it will lock up since the input shaft and gears will be disconnected.

Why Does the Pilot Bearing Fail?

A car’s components will all eventually stop working. But the issues lie in failures that occur too soon or irregularly. These are the most frequent reasons for a defective pilot bearing, which is a serious issue.

1. An Input Shaft Bearing That Is Failing or Has Failed

The input shaft bearing is the first bearing in the transmission and is located on the input shaft of the gearbox.

The clutch pedal rattles as the driver changes gears, which is another blatant indicator of a bad pilot bearing. When the pilot bearing is operating properly, the clutch depresses steadily and smoothly.

In essence, the input shaft is maintained in alignment, stability, and security by the transmission’s input shaft bearing and pilot bearing. Except for the pilot bearing and input shaft bearing touching opposite ends, they are the same item.

The pilot bearing will endure more strain and deteriorate more quickly if the input shaft bearing is failing.

2. A Tilted Input Shaft

To maintain alignment, the input shaft has to be straight. The bearings will be under stress if it bends.

3. A Defective Input Shaft

The transmission was expertly constructed. Any flaw in the input shaft will have an impact on both the bearings that keep things in place and rotation.

4. Failure In the Input Shaft Bearing

Any mass-produced component has the potential to be faulty from the start. The same problems that arise from a flawed input shaft or a bent input shaft can arise from a poor input shaft bearing.

How Is the Pilot Bearing Diagnosed?

There is a concern if noise starts to emanate from the transmission’s bell housing region. The clutch release bearing and the pilot bearings are both located there. Either bearing might be the problem.

A road test is the most effective approach to determine the pilot bearing’s condition. The clutch release bearing and the pilot bearing cannot be distinguished without using the gearbox and changing gears.

Listen for the aforementioned sounds while driving the car, as well as any other noise that could occur when the gearbox is in gear.

Then, with the gearbox in first gear, let off the clutch pedal. If there is noise in this scenario, worn release bearings or worn pilot bearings are definitely to blame.

Push the clutch pedal down and shift into Neutral to see whether the issue is a worn clutch release bearing or the pilot bearings. If the noise persists, the clutch release bearing is likely to malfunction. If the noise stops, the pilot bearing is the cause of the issue.

A Bad Pilot Bearing: Removing and Fixing It

The clutch component must also be removed along with the transmission before you can start.

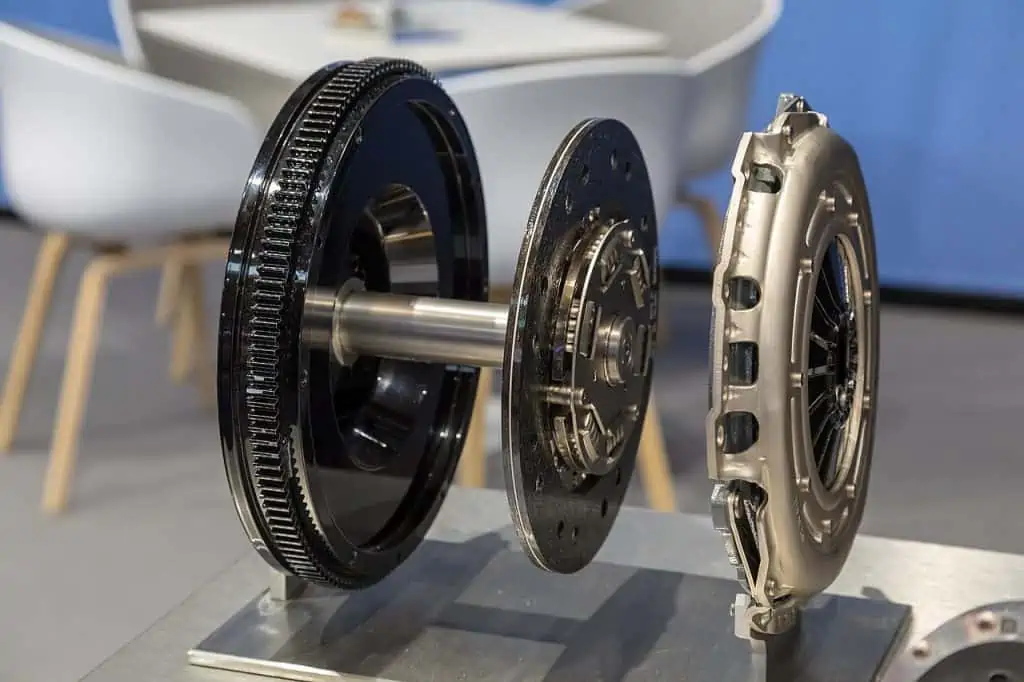

Flywheel, friction disk, and clutch kit by Matti Blume / CC BY-SA 4.0. Periodically, the oil in the self-lubricating pilot bearing runs out. This keeps the transmission’s input shaft from stopping spinning, preventing the clutch from disengaging. The input shaft and clutch disc might then wander inside the pressure plate and flywheel as a result of the needle rollers in the bearing separating at this point.

Which Ones are the Needed Tools and Equipment?

You require a pilot bearing removal tool known as a pilot bearing puller to correctly remove the pilot bearing. One may be rented at your neighborhood auto parts store or purchased on Amazon starting at $34.00.

Without it, the task would be challenging to complete. After obtaining the necessary removal tool and removing the complete transmission from the vehicle, you may start with these steps:

Step 1: Put the Pilot Bearing Removal Tool In

Insert the tool into the pilot bearing once the jam nut has been completely backed off. Then, rotate the handle in a clockwise direction to extend the tool’s fingers behind the bearing. The tool’s body will rest up against the flywheel, supporting the pulling motion.

Step 2: Pull Out the Old Pilot Bearing

When you firmly grasp the tool and tighten the jam nut with a wrench, you will hear a slight “pop.” This will serve as a warning when the pilot bearing begins to move away from the crankshaft.

The nut will now become simpler to move as the wrench tightens. Keep doing this until the bearing has been completely taken out.

Step 3: Examine the Pilot Bearing’s Socket

Examine the end of the crankshaft and the bearing that will be retained in the tool once the bearing has been removed. By rotating the tool handle the other way, the bearing may be released.

Clean the crankshaft end where the replacement bearing will be placed with a shop towel. To maintain the bearing in place while it is operating, you need to keep this surface clean and grease-free.

Step 4: Examine If the New and the Old Pilot Bearings Match

Verify that the internal and exterior diameters of both the new and the old bearings are the same.

There can be no exceptions since the replacement bearing either won’t fit into the crankshaft or won’t enable the input shaft of the gearbox to fit inside of it, which prevents the transmission from being reinstalled.

Fit the pilot bearing over the input shaft while the gearbox is off to ensure that it will function.

Step 5: Set Up the New Pilot Bearing In Place

Putting the bearing in the freezer for around 30 minutes will cause it to significantly shrink, making installation easier. The bearing should then be carefully inserted into the crankshaft’s end.

Internal combustion engine by Till.niermann / CC BY-SA 3.0. To entirely decouple the gearbox from the engine is the clutch kit’s goal. As a result, if any of its components become defective, the clutch kit struggles to complete and properly carry out its role.

Tap the bearing into place carefully with a hammer and metal drift. When the bearing is fully placed, the hammer will feel sturdy. To prevent injuring the bearing, don’t strike it too hard.

Step 6: Keep the Pilot Bearing Lubricated

To guarantee the pilot bearing’s good performance, lubrication is required. Apply a little amount of silicone-based lubricant or axle bearing grease to the inside of the bearing.

To prevent putting oil on the clutch disc, flywheel, or pressure plate, don’t apply too much. The transmission has to be fitted again, and the clutch is now prepared for replacement.

How Much Does the Pilot Bearing Replacement Cost?

If you’re performing the work yourself, you can get a pilot bearing for anywhere from $7.00 and $23.00 (US) from Amazon or your neighborhood parts store.

The gearbox and clutch must be removed to do this work, and labor costs range from $350.00 to $650.00. (US). The pilot bearing may be included if you’re replacing the clutch entirely in a kit. To be certain, examine the kit’s components.

What Is the Lifespan of a Pilot Bearing?

A pilot bearing should last the clutch’s lifetime, however as bearings wear out over time, they can fail between 45,000 and 65,000 miles after installation.

Is It Safe to Drive with a Bad Pilot Bearing?

You shouldn’t, is the quick response. Driving with a broken pilot bearing increases the risk of damaging the transmission input shaft and necessitating transmission replacement.

From a purely technical perspective, you might be able to drive with a damaged pilot bearing for a short period.

The Conclusion

You will be able to detect bearing failure after you are aware of all the signs of a defective pilot bearing and its function. Visit a skilled technician to inspect, identify, and resolve the issue if you experience any of these symptoms.

Given that it requires removing the clutch kit from the vehicle and dismantling the transmission, this is not a DIY project. Advanced level expertise and the usage of specialized tools are needed for the procedure.

Car Transmission by Ritchyblack / FAL.

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”