The ball joint is a critical component of your vehicle that enables your car to travel freely and smoothly in all directions. Ball joints do not easily wear out, but they might become defective over a while. When this happens, your vehicle may not move as readily or freely as it once did. A ball joint may simply become loose and fall out of its socket in

some instances. However, ball joints frequently fail owing to wear and strain, as well as the impacts of friction, heat, and cold.

Replacement Cost of a Ball Joint

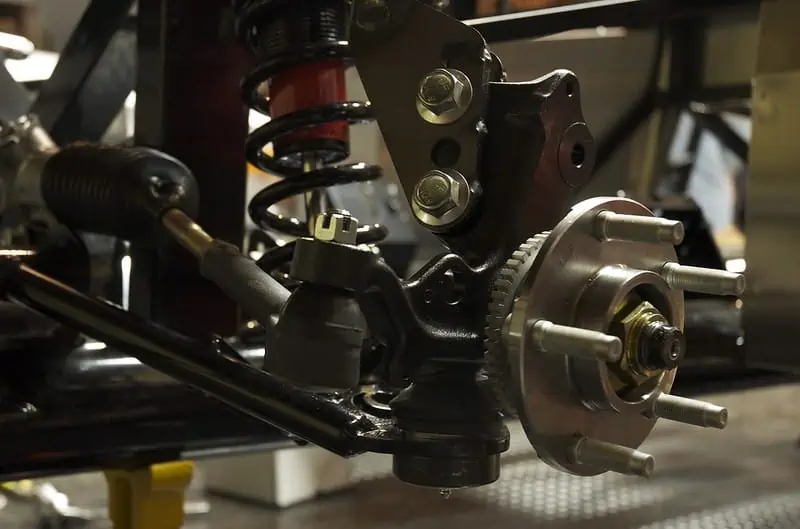

The ball joint connects the steering knuckle to the control arm of the vehicle.

The cost of replacing a ball joint varies from vehicle to vehicle and is dependent on the brand and model of the vehicle. For instance, replacing a ball joint in a Honda CR-V costs $130 on average with $35 for parts and $95 for labor, while replacing a ball joint in a Ford Focus costs $173 on average, with $68 for parts and $104 for labor.

In general, replacing a ball joint is not prohibitively costly. In most circumstances, you should anticipate paying roughly $300 for both components and labor. Most ball joints cost between $100 and $150, while labor costs between $150 and $200. An independent repair business will nearly always be less expensive than a dealership.

Other factors may influence the overall cost of this repair. More costly parts are typically required for higher-end automobile models. For example, replacing a ball joint on a Mercedes or BMW could cost $500, but the same work on a Toyota, or Chrysler could cost $250.

Additionally, if extra parts need replacements simultaneously, it might raise the cost higher. It’s conceivable that both the upper and lower control arms’ ball joints may need replacements rather than simply one.

Types of Ball Joints

Upper and lower ball joints by Craig Howell / CC BY 2.0. In this sort of suspension, the lower ball joint is the weight-carrying joint, while the higher ball joint is the follower, with no major load to support. It merely serves as a second pivot point for steering.

Ball joint types are generally grouped into three categories; design, position, and usage.

- Design

Ball joints can be greasable or sealed. Sealed ball joints are lubricated for life, so you do not need to apply grease regularly. They are the most popular contemporary ball joint design among car owners. These ball joints require little maintenance. However, they are not serviceable and can only be thrown out after wearing out.

The greasable ball joints are an old design. They are, nonetheless, still widely used today. They are most commonly seen in light passenger vehicles or huge trucks that must sustain some weight. They require constant grease addition, making them high-maintenance components.

Greasable ball joints have a fitting called a nipple that allows lubrication to be applied. When these ball joint types are not lubricated, they wear out quickly.

Ball joints can also be mounted in a number of ways. They can be bolted, screwed-in, press-in, or riveted. Press-in ball joints are the most common in new vehicles, but aftermarket ball joints frequently include the other mounting choices.

- Position

There are two ball joints: lower and upper. Some cars have a lower ball joint, while others employ both. Trucks, for example, use a lower ball joint to sustain the weight and a supplementary higher ball joint for critical purposes.

To resist the stresses they are frequently subjected to, the lower ball joint is generally bigger. Lower ball joints wear out quickly due to the weight they must take, especially if large luggage is carried in the vehicle or driving conditions are severe.

Ball joints are also seen in the back wheels of vehicles with independent rear suspensions. These provide steering as well as pivoting and weight support. In other words, they fulfill the same function as the front ones.

- Usage

A ball joint in a car might be “load-carrying” or “follower.” These two kinds of ball joints serve distinct purposes. A load-bearing ball joint supports weight, making it a vital suspension ball joint while a follower ball joint is intended to pivot for the steering system of an automobile. It is referred to as a pivot ball joint because it allows the steering system to freely swivel for improved vehicle control. These ball joints are often found on the upper suspension component.

Upper ball joints are generally follower kinds that sustain minimal weight. Lower ball joints are sometimes referred to as “load-bearing” because of the amount of weight they must support. An exception to this is the MacPherson strut suspension. In this suspension, each wheel is equipped with a single control arm and ball joint.

The lower ball joint in the MacPherson suspension can act as a follower type. The upper strut in this suspension supports the vehicle’s weight and is supported by an elastomeric bearing. The steering knuckle is connected to the strut.

Parts and Functions of the Ball Joint

An upper ball joint by Ryan Frost / CC BY 2.0

A ball joint consists of three parts: the knuckle, the socket, and the bolt. The knuckle is the piece of metal that is attached to the vehicle frame and the two axles. The socket is the part of the ball joint that fits into the knuckle. The bolt holds the ball joint together and is inserted into the socket. The ball joint can move up and down, side to side, and rotate around the bolt. A bump in the road surface causes the axle to move up and down, causing the knuckle to move along with it; this movement is what allows your vehicle to absorb the shock of bumps in the road and continue moving.

It is located at the center of each wheel and allows the wheel to move smoothly in all directions. On front-wheel drive vehicles, it also allows the front wheels to turn, allowing the car to make sharp turns smoothly. Additionally, ball joints allow the axle to move smoothly and pivot around the hub in response to changes in the weight of the vehicle. It also absorbs vibrations and reduces road noise and harshness during travel. When the ball joint fails, it can cause the axle to bend or break, preventing the vehicle from moving properly. These functions make the ball joint one of the core components in vehicle suspension.

Causes of Ball Joint Failure

A worn-out ball joint by Pixel / CC BY-NC 2.0

A ball joint can fail for a variety of reasons but the main causes include age, wear and tear from regular use, collisions, rust, corrosion, debris, road conditions, and over-tightening.

- Age

As ball joints age, they become less stable and can fail in a collision or during adverse weather conditions. This can lead to premature wear and tear on the axle, differential, or other components. If not fixed, this can cause serious damage to your car.

- Wear and tear

Worn-out ball joints can lead to vehicle instability and loss of control. Ball joints wear out over time and need to be replaced after a certain number of miles have been driven. A mechanic can tell if a ball joint is worn out by gently pressing on it with his fingers. If the joint feels loose or if it makes a clicking sound, it should be replaced.

- Collisions

A collision can damage both a vehicle’s suspension and ball joints.

The Front suspension of a vehicle by Dylan Conway / CC BY-NC-ND 2.0. The suspension of a vehicle is the system of tires, tire air, springs, shock absorbers, and linkages that connects a vehicle to its wheels and allows them to move relative to one another.

Damage to the ball joint can allow the wheel to move erratically or not at all. In the event of a front-end collision, the steering linkage may become damaged or misaligned. The vehicle could then pull to one side or become difficult to control.

- Rust and corrosion

Corrosion can cause a ball joint to fail due to the metal being too weak to support the vehicle’s weight. Corrosion can also weaken a ball joint, causing it to crack and separate.

- Debris

Road debris can cause a ball joint to become trapped. Debris can enter a ball joint as a result of driving through mud or snow. Debris can potentially cause a ball joint to fail if it enters via the boot seal.

- Road conditions

Ball joints typically last around 150,000 miles, but this can be greatly affected by road conditions. Rough roads cause more stress on the joints and can cause them to wear out prematurely.

- Over-tightening

Over-tightening a ball joint can cause it to become loose and wobbly. This can occur when a bolt holding the ball joint in place has not been properly tightened or if the nut has been over-torqued. An over-torqued nut can strip or cross the thread on the ball joint and cause it to fail.

Symptoms of a bad ball joint

Image indicates lower ball joint failure by Matthew Bellemare / CC BY-SA 2.0. A defective ball joint no longer limits the angle of the wheel, causing the entire strut to sit outside of its proper position.

- Vehicle instability

If a ball joint is defective, the vehicle can become difficult to control. The vehicle may pull to one side or feel unstable when turning. If you press on the steering wheel and feel any wobbly movement, this is a symptom of a faulty ball joint and should be checked out by a service expert.

- Clicking noises

A clicking noise coming from the front end of your vehicle means there is a defective ball joint in one of your wheels. When turning a corner at slow speeds, a damaged ball joint will create a clicking noise. It may also be difficult to drive in a straight line. This noise can be caused by the ball joint moving around or being loose.

- Wheel movement

If the ball joint is damaged, the wheel can move erratically or not at all the way it should. If a wheel moves loosely, it could be a sign that a joint has broken inside the socket or has become damaged internally.

- Difficulty steering

If the ball joint is damaged, it can cause difficulty in turning the vehicle. Also, it could cause the steering to vibrate erratically. If the ball joint is loose, it can cause movement in all directions, not just to one side.

- Uneven tire wear

If the ball joint is loose, it can cause the tires to wear unevenly. This is because the ball joint can cause the car to shake and vibrate, which then causes uneven wear on the tires.

How to Protect Your Vehicle’s Ball Joint

There are a variety of ways to protect the suspension components of your vehicle from wear and tear caused by potholes, rough roads, etc. One obvious method is to drive your car over less rough and uneven terrain whenever possible. Another way to protect your suspension is to use an all-terrain vehicle tire. All-terrain vehicles have wider tires that provide more cushioning and support when driving over bumpy terrain. Another method is to equip your vehicle with suspension lift kits and wheel spacers. This will raise the height of your tires above the ground, providing additional protection from damage. Suspension lift kits may also give your vehicle a more aggressive appearance and can provide higher ground clearance for easier off-roading.

Additionally, lubricators can be used to coat and protect the vital parts of your suspension from rust and other corrosion. Lubricants also help to reduce the friction between the suspension components, which can help to keep them from wearing out prematurely.

Can I Replace my Vehicle’s Ball Joint myself?

The answer is yes. Although it’s best handled by a professional because of the special tools and knowledge needed, you can carry out the replacement yourself to save cost. Begin the procedure by removing the front wheel, which contains the faulty ball joint. After that, remove the axle nut and then the caliper. Take extra care not to harm your brake lines or ABS circuitry. This is also an ideal opportunity to examine your wheel bearings for deterioration. You may save money on a wheel-bearing replacement if you undertake the task when everything is already disassembled. After that, disconnect the control arm from the steering knuckle and the steering knuckle from the ball joint. You can now use a ball joint press to remove the old ball joint.

Then, using the ball joint press, install the replacement ball joint. You will also need to install the replacement grease fitting on the ball joint if it is provided. There will be no grease fitting if your car has a sealed joint. Return the steering knuckle and control arm to their original positions. Replace the brake caliper, axle nut, and wheel. After this, have a wheel alignment done. It is essential to always do so after removing your front suspension components. Fortunately, a wheel alignment costs less than $100 on average.

How long should a Ball Joint last?

On average, a ball joint should last at least 100,000 miles, and under normal driving conditions, ball joints may live much longer. Because most ball joints survive so long, they are not usually covered by a warranty. They are not products that require preventative maintenance. Ball joints are typically only replaced when they wear out or fail. If your ball joint fails while your automobile is still under warranty, you should be able to get it fixed for free.

How often should I check my car’s Ball Joint?

Ball joints should be checked regularly to ensure that they remain in good condition and are not damaged in any way. The best time to check a ball joint is after the vehicle has been driven around for 30 minutes or so; when the ball joint will be at the proper temperature to perform a proper inspection. You should check your ball joint each time you perform an oil change.

Can I drive around with a bad ball joint?

It is not recommended that you drive around with a defunct ball joint, as this can lead to further damage and may even result in a complete loss of function. If you do notice that you have a bad ball joint, it is best to take your vehicle to a qualified mechanic for repairs.

Conclusion

Installing suspension components such as ball joints should always be done with care and precision. Also, by checking and changing your ball joints on a regular basis, you can ensure that your car retains its performance and appearance for years. If you prefer that your mechanic replace the part, make sure to discuss your unique needs with them so that they can offer the best solution for you and your vehicle. In any event, having your suspension tested and fixed regularly is usually a good idea.

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”