Any vehicle’s powertrain has a significant role in its output. Starting with the engine and moving on to the suspension and gearbox, this portion of the car is made up of everything.

The electricity for your automobile is also produced by it. The frequently overlooked flywheel is a crucial part of the powertrain. But, how much does a flywheel replacement cost?

It is easy to overlook the flywheel in favor of all the glitzy accessories and expensive parts. It is, nevertheless, a very crucial part. Please read this if you don’t want to spend a lot on your flywheel replacement cost.

Any car’s performance might suffer significantly from a faulty flywheel. Learn about flywheels, their functions, how to tell when one is failing, how much it will cost to repair a flywheel, and much more.

The flywheel replacement cost is typically around $200 for parts or $1000 for parts plus labor, with materials costing on average $170 and labor costing on average roughly $750.

We’ll examine elements that impact both the labor cost of vehicle repair as well as ones that affect the flywheel replacement cost of parts to understand why costs vary.

We will also go through strategies to cut costs on the job and the overall flywheel replacement cost.

What is a Flywheel?

A flywheel is a large wheel that is fastened to a spinning shaft to smooth the transition of power from an engine to an apparatus.

In automotive engines, the flywheel functions to balance out the energy pulses produced by combustion in the cylinders and to supply energy for the pistons’ compression stroke.

The Function of a Flywheel

A flywheel, which consists of mass moving around an axis, functions as a mechanical battery.

It operates by accelerating a rotor to extremely high speeds and keeping the energy in the system as rotational energy. It stores energy in the form of kinetic energy.

Due to the variety of functions it serves, the flywheel may be found in practically all car types.

Motor Balance

Every piston fires at a different angle as a result of the offset from the center of the crankshaft vibration and wobbling. In this scenario, the flywheel’s purpose is to stop the side-to-side motion.

Due to the flywheel’s substantial weight, this is accomplished. Because the engine is balanced on the mounts and is steady, the flywheel lessens vibrations across the entire engine.

Vehicle Start

When starting the engine, the flywheel also has a function to play. The starting motor is linked to the gear teeth on the flywheel.

When the automobile begins, the starting motor rotates the flywheel in the direction of the ignition key.

As soon as the engine starts to spin, the combustion impact keeps it going. The flywheel causes the starter motor’s Bendix gear to retract, allowing unfettered rotation.

It Reduces Stress on the Drivetrain

Controlling engine speed is a further function of a flywheel. Additionally, it decreases drivetrain component wear and tear and smooths out engine speed.

Additionally, the flywheel reduces wear between the driveshaft and the gearbox shaft. A universal joint connects these two.

Flywheel Replacement Cost Warning Signs

At idling, terrible sounds are the most typical sign of a damaged flywheel. Additionally, you may experience vibrations, gear slippage, or burning odors emanating from the transmission. Other shifting problems could also be seen.

These are the most common symptoms, albeit they are not the only ones that might exist. The most common signs of a bad flywheel are listed in further detail below.

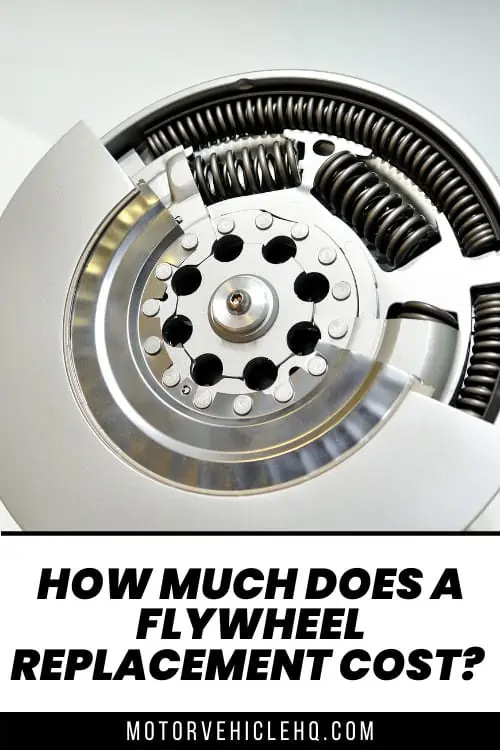

Obnoxious Noises When Idling

The transmission will undoubtedly make a lot of noise when the engine is idling if your vehicle has a double-mass flywheel, which many new vehicles have. This only occurs if your particular automobile model has a double-mass flywheel.

Slippage in Gear

Gear slippage may occur if the area to which your clutch is fastened is particularly worn out or has a poor surface.

When you change to a higher gear and the engine RPMs rise but the speed of the wheels remains constant, gear slippage occurs. More often than not, you’ll need to replace the clutch and flywheel the longer the issue persists.

Burning Odor

Even while improper use is the most frequent cause of a burning clutch, if you’re following all the correct procedures, it’s an indication of a more serious mechanical issue.

If you smell a burning clutch, you should either reconsider your driving style or replace the flywheel or the clutch.

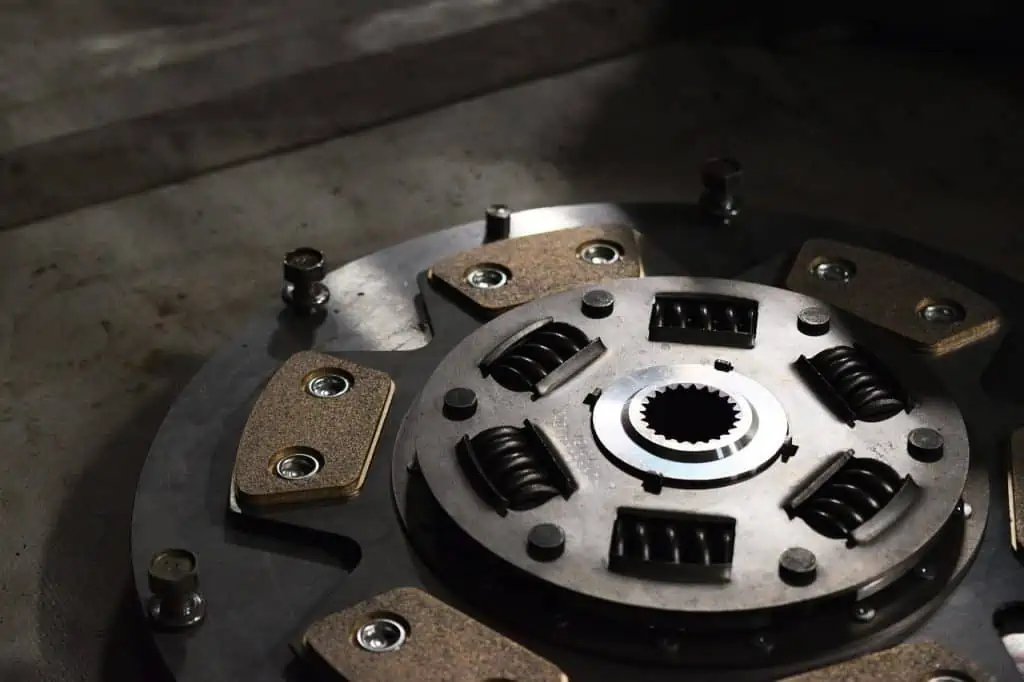

Clutching Vibrations

Worn pressure plates, clutch discs, or release bearings are just a few of the issues that might cause clutch chatter.

A bent flywheel, however, is a further possible factor. Even if it’s not the most frequent reason, you should nonetheless investigate it.

Variable Starting

The flywheel is covered in teeth all the way around. To turn the engine over, your starter attaches to the starting ring, which is made up of these teeth.

These teeth can wear out over time and crack, which causes the starter to grind while attempting to connect with them.

When you try again, it ought to start if the teeth are the issue. When you have a fractured tooth, the issue is sporadic and will get worse as time passes without being fixed. If you put it off for too long, it will worsen and harm your start.

What Causes Flywheel Damages

Untimely wear and failure are caused by several causes. Some of the most common reasons are listed below.

- Inadequate upkeep. Other parts may suffer damage or alignment issues if replacement starters or clutches are not installed correctly. To further emphasize this point, it is strongly advised to replace the clutch as soon as possible if it sustains damage. Clutches are significantly simpler and less expensive to replace than flywheels, which will be affected if you leave them.

- Driving style and engine condition. For instance, it could be brought on by sluggish cranking rates, high loads, driving in the wrong gear, and the difficult engine starts.

- Overheating. This is frequently brought on by a sliding clutch and can be fatal for the discs since they can deform or shatter.

How Much Does a Flywheel Replacement Cost?

Any vehicle repair project’s price must be split into the cost of labor and the cost of the parts.

Others will have to pay higher prices for expert vehicle body repair, while others will merely pay for the parts and perform the labor themselves.

The Cost of the Parts for a New Flywheel

The following cost estimate (materials alone) is for those who want to replace the flywheel on their own or with the help that is provided for free or at a significantly discounted cost other than that provided by a professional car mechanic.

We’ll also talk about the expense of labor in the next section because not everyone can do this component replacement project on their own.

Paying only for the parts and completing a DIY project can drastically reduce typical expenditures. Depending on your car’s model and manufacturer, a flywheel replacement will typically cost you approximately $200.

Depending on the components you select, prices can range widely, but on the high end, they can go from just under $70 to several hundred dollars or more.

Flywheel Replacement Cost of Parts and Labor

The question of how long would it take to replace a flywheel? must be asked. to understand how much labor costs. Knowing the answer to this question may help you calculate labor expenses because most automobile work is done hourly.

You may calculate your average labor cost by multiplying it by the length of time it usually takes to replace this crucial component.

Therefore, we must start by examining the national average for labor costs in the vehicle repair industry. In many instances, replacing a vehicle’s flywheel correctly might require anywhere from 6 to 8 hours of effort.

The cost of labor comes out to an average of $717.50 when the average hourly rate of $102.50 is multiplied by the average length of 7 hours.

You may start to notice the savings in changing the flywheel yourself because the labor cost in this situation is substantially more than the cost of the materials. The total will be close to $887.50 when labor and component costs are included.

Of course, your labor costs may vary based on where you reside and the sort of shop you are hiring from.

Additionally, if the mechanics are available and skilled enough, you may find that your rates drop as a result of a shorter work period overall.

Long-Term Flywheel Replacement Cost

What is the flywheel replacement cost over time? How many times will it require replacement during the vehicle? Along with queries regarding the general flywheel replacement cost, these are queries you could be posing to yourself.

While it’s impossible to determine with certainty how frequently you’ll need to replace the flywheel in your car, it’s reasonable to assume that it won’t be necessary very frequently.

A flywheel should only need to be replaced a few times in a car’s lifespan, at most, similar to engine replacements and other large part replacement tasks.

However, because severe wear affects the clutch, vehicles that go through regular wear and tear will probably require this component changed more frequently. The flywheel is also impacted by the clutch.

However, it should only be necessary to replace the flywheel a few times throughout a car’s lifetime, or once every 90,000 miles.

If you bought your car brand new, you could need to have this repair work done twice throughout driving the same vehicle because an automobile’s lifespan typically consists of roughly 200,000 miles.

The average lifetime cost of replacement would thus be $340 for components only or $1,774 for parts and labor.

Factors Affecting Flywheel Replacement Cost

You can’t anticipate all vehicle repair jobs to cost the same amount, even though the average flywheel replacement cost is similar to the figures we provided above. The cost of this project might vary for each person depending on several factors that are at play.

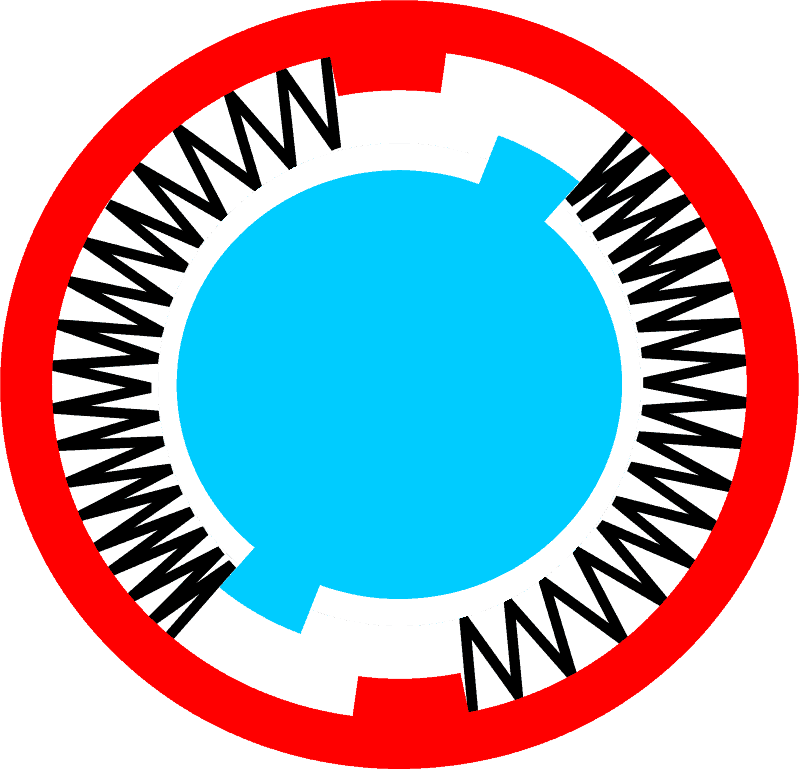

Dual-mass flywheel section by Cschirp / CC BY-SA 3.0

The Fluctuating Cost of Labor

Your state’s or area’s labor costs may be very different from those in another location.

Additionally, the cost of labor in a given area may vary depending on a variety of factors, including the local cost of living, business costs, the kind of car repair company (independent vs. dealership-based), and more.

The national average for vehicle repair labor costs is around $102.50 per hour, with the lower extreme being just over $70 and the upper extreme being just below $130.

The Cost of Related Repairs

Indirectly, having linked car repairs can raise the price of flywheel replacement.

For instance, issues with a car’s clutch and flywheel are frequently related, so you could find yourself having to pay for clutch repairs when your flywheel is replaced.

Regular Maintenance

The frequency with which your flywheel has to be replaced depends on how often and how promptly you undertake maintenance on your vehicle.

If you don’t maintain the vehicle and take care of problems when they happen or when routine maintenance is required, you can wind up having to replace your flywheel more frequently and at a higher total cost.

Labor Done by Professionals vs. DIY

Simply by eliminating the expense of labor, a DIY solution will be much less expensive than a replacement done at an auto body shop.

Alternatively, if you can enlist the services of a friend who is skilled in mechanics, they could be prepared to complete the task or assist you in doing it at a far lower cost.

How to Reduce the Flywheel Replacement Cost.

There are several ways for customers to reduce their costs when purchasing replacement auto components. Besides doing it yourself, consider these other options:

Shop Around for the Best and Compare Prices.

You should check prices across manufacturers and online sales channels before purchasing any goods. The same is valid for vehicle body businesses, which you could occasionally use.

It is not embarrassing to call repair facilities to obtain hourly estimates before making a purchase. You may also discover a distinction between purchasing parts from physical locations and online merchants.

Look for Discounts.

Always inquire if the vehicle repair business has any additional coupons or discounts that they may use on your purchase. You cannot know when particular staff could be able to contribute one, even though it would be a long shot.

If at all Possible, Avoid the Dealership.

Avoiding dealership costs is a wise policy when it comes to vehicle maintenance and repairs. For vehicle bodywork, dealerships are notorious for charging more than independents and national chains. An expensive job like replacing a flywheel makes it more likely that you will be overcharged.

Principle of dual-mass flywheel by Kaboldy / CC BY-SA 4.0

When Online Shopping, Use Cheap Browser Extensions.

Installing a browser extension that can automatically compare discounts throughout the web to offer you the greatest bargain can be worthwhile if you’re wanting to buy a new flywheel online.

Is a Damaged Flywheel Safe to Drive on?

No. In a manual transmission vehicle, the flywheel assists in transferring power from the engine to the clutch disc and then to the wheels.

It functions as an energy storage device and aids in maintaining the engine’s smooth operation. Without it, operating the vehicle would be extremely challenging, if not impossible.

The flywheel is a crucial component of an automobile’s engine. When the engine requires it, they unleash the energy they have stored.

Clutch engagement may be compromised if a flywheel is destroyed. A flywheel can occasionally be fixed, but there are rare situations when it must be replaced.

If you are unsure if you can drive your car with a damaged flywheel, you should take it to a technician to have them have a look.

They’ll be able to advise you on the necessary steps and whether it’s safe to drive your automobile at this point.

It might be possible to operate an automated vehicle without a flywheel. Instead of relying on the flywheel, the gearbox will use the engine’s force to rotate the driveshaft and wheels.

With an automatic gearbox, the engine will lug down when you are parked, and this can lead to unnecessary engine and transmission wear.

How to Replace a Bad Flywheel

Flywheels must be replaced if they are fractured or otherwise damaged. While not very challenging, the replacement might take some time. We’ll go through how to change a damaged flywheel step by step.

- The transmission cover must first be taken off. Pulling it out after releasing the bolts and holding it in place will do this. You can see the flywheel once you’ve taken off the transmission cover.

- The flywheel must be taken out next. Bolts holding it in place can be removed to do this. Since each bolt will eventually need to be replaced, make a note of where it goes.

- You may install the new flywheel after removing the old one. Bolts will be included with the new flywheel, so you won’t have to worry about looking for replacements. The replacement flywheel may be installed by simply doing the same process backward.

- You must torque the bolts after installing the new flywheel. A torque wrench can be utilized for this. The installation instructions for your flywheel will give the torque recommendations.

- You may put the gearbox cover back on once the bolts have been torqued. To install the transmission, only carry out the same procedures in reverse.

Final Thoughts

Generally, labor and component expenses will make up the majority of the usual flywheel replacement cost. While labor will run you about $800, the average replacement flywheel will cost you about $200.

Consequently, the average cost of a DIY project comes to approximately $170, which is roughly $700 less expensive than paying for both supplies and labor.

When a person needs to replace this component in their vehicle, they will discover that several variables affect the overall cost, including the location’s impact on labor costs for automobiles, the price of related repairs, and variations in the cost of cars of different makes and models, and more.

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”