In a way, the automotive industry underwent a revolution in the 1970s. The current generation of newly enacted emissions rules put increasing pressure on US automakers to lower their carbon impact. However, doing so proved to be rather challenging and ultimately called for the introduction of new emissions control technologies.

These new parts, despite appearing to be sturdy on the outside by design, all eventually failed due to aging and normal wear and tear. Fortunately, the majority of these failures are identified and recorded by a vehicle’s onboard diagnostic system as an active diagnostic issue code.

Few of these diagnostic fault codes for emissions are as popular as DTC P0405. This fault code indicates a problem with the circuit that controls a vehicle’s exhaust gas recirculation. A failure in the EGR sensor A circuit, which eventually affects a vehicle’s exhaust production, is what this code explicitly indicates.

Continue reading to find out more about diagnostic trouble code P0405 and how to resolve similar problems should they occur in the future.

P0405 Code: What Does It Mean?

The “Exhaust Gas Recirculation Sensor A Circuit Low” Diagnostic Trouble Code (DTC) P0405 means that the circuit is low. It means that the EGR valve position sensor’s results indicate lower voltage levels than usual.

The EGR position sensor, as its name suggests, determines where the EGR valve is located. The sensor signal is used by the powertrain control module (PCM) to track and modify EGR valve operation. The PCM may set a P0405 code if the sensor’s signal seems unusually low.

The exhaust gas recirculation (EGR) system and associated sensor for your engine are both mentioned in the P0405 error code. The purpose of the EGR system is to keep nitrogen oxide (NOx) emission levels within reasonable bounds. The EGR sensor communicates with the Powertrain Control Module to monitor the EGR valve (PCM). The P0405 code is set off when the PCM notices a voltage level that is lower than usual.

Electronically actuated EGR Valve by Towel401 / CC BY-SA 4.0. The P0405 fault code refers to both the exhaust gas recirculation (EGR) system and the related sensors for your engine.

The PCM regulates and modifies the EGR valve’s functioning using the signals from the EGR position sensor. The exhaust gas will be sent back into the combustion chamber by the EGR system, which also specifies the exact route for the gasses.

Since exhaust gas by itself is inert, it is utilized to dispense various fuel/air mixes to maintain normal combustion temperatures, occasionally producing too much nitrous oxide. The EGR also controls the flow of exhaust gas from the exhaust manifold into the engine’s intake manifold.

This action is carried out by a pintle under the control of the PCM. The PCM will also receive data from the throttle position (TP) sensor and the engine coolant temperature (ECT) sensor throughout this operation.

The manifold absolute pressure (MAP) sensor values will also be used to establish the pintle’s location. The P0405 code is set if the PCM detects an EGR position sensor signal that is less than what it considers to be acceptable throughout this operation.

If the EGR position sensor signals a greater voltage reading than anticipated, the PCM will set the P0406 code.

What Is Key Information About EGR Valves and Their Components?

It’s worthwhile to spend some time learning more about an EGR valve replacement cost before we discuss how much it costs. So what exactly is this EGR valve? The “exhaust gas recirculation” valve is what it is officially known as, and as the name implies, that is also its main purpose. The EGR recycles too many emissions back to the engine as part of the engine management system.

To put it another way, the EGR recycles exhaust gases produced during the combustion process. However, you might wonder why you would desire this. There are several valid explanations for this. First off, the EGR reduces emissions by sucking excess pollution out of the tailpipe. Additionally, by reducing waste, returning those exhaust gasses to the intake increases engine efficiency.

This indicates that over time, fuel consumption will be reduced. Keep in mind that engines heat up quickly. It’s really warm in there, with temperatures reaching at least 1,370°C. These exhaust gases are only briefly ingested by the EGR. The gases include a variety of harmful gases, such as nitrogen oxide. The chemical composition starts to change as soon as they re-enter the intakes.

These once-toxic gases mix with oxygen and diluted the air mixture. This now-diluted combination burns more slowly when it ignites, which can reduce combustion chamber temperatures by almost 150°C. Along with that, your tailpipes emit less nitrogen oxide (NOx). Better knock tolerance and aiding in lowering diesel knock at idling are two further advantages.

Where are the EGR Valves and Their Systems Located?

Depending on the make and model of the car, the EGR valve is located differently. Find the exhaust manifold for the engine to assist you in finding it. It should have a pipe or line coming out of it; this is the line for the EGR system.

The EGR valve is along that line. The valve features a cylindrical body with two connections and a metal casing in the form of a circle on top. When held upright, it resembles a towering mushroom in a way.

For access, you may need to remove the engine’s plastic cover on some vehicles. The best course of action if you’re having trouble finding it is to reference your service manual.

The location of the EGR valve varies depending on the make and model of the vehicle. To help you find it, locate the engine’s exhaust manifold. The pipe or line that should be coming out of it is the one for the EGR system.

What Symptoms are Associated with a P0405 Code?

The P0405 code’s initial symptom is the PCM turning on the Check Engine Light in your dashboard. If the voltage measurement is too low, the PCM may also open the EGR valve more frequently than usual, causing your engine to stall down.

Because of the insufficient air and fuel mixture, will also make your engine hesitate when accelerating. Your vehicle may also have harsh and inconsistent idling due to the EGR system. Additionally, it’s conceivable for your engine to start producing more NOx, which can potentially result in you failing emissions testing.

You can also observe a decline in fuel efficiency and engine performance during this problem. Here are the P0405 symptoms in more depth that you might experience:

1. Issues with Engine Performance

Engine performance problems are the first sign of a faulty EGR valve, and they can appear in a variety of ways. First, you could notice that the car accelerates slowly and feels as though there has been a loss of power.

The EGR valve is typically stuck open, which prevents the engine from adjusting the fuel and air mixture to compensate. The engine cannot operate at maximum power if the fuel and air mixture is improper.

Additionally, it can cause a harsh idle. At operational temperature, most cars typically idle between 600 and 800 rpm, and they should be steady at that RPM. A rough idle is when the needle jumps while the engine is running, and a faulty EGR valve might also be the cause of that.

If the issue is serious, the engine may completely stall. In this instance, stalling may occur as a result of the engine not receiving enough fuel or air, which may occur as a result of a faulty EGR valve.

The car’s air and fuel combination can be ruined by a defective EGR valve, to put it simply. Performance problems will occur if the Engine Control Unit (ECU) is unable to correct this.

2. Smell of Gasoline from the Exhaust

It’s common to smell running exhaust if you’re close to your car’s tailpipes. However, if you detect a strong odor of gasoline inside the cabin, this may indicate a malfunctioning EGR valve.

High levels of hydrocarbons that are emitted into the exhausts and out of the tailpipes are the cause of this odor. The fact that the EGR valves are stuck shut is obvious. As a result, it is unable to facilitate the recirculation process.

3. Bad Emissions Test Results

The emissions control system in your car includes the EGR. Consequently, a damaged EGR valve could cause your car to fail an emissions test if you subject it to one. Any one element of your car’s emissions system, if it malfunctions during the emissions test, has the potential to cause it to fail.

Unfortunately, this implies that pinpointing the actual root of the issue might be challenging. The EGR valves may not always be the actual cause of an emissions test failure. Furthermore, not all of your car’s components undergo emissions testing, so diagnosing it this way might be challenging.

OBD2-Scanner Display by KarleHorn / CC BY 3.0. You need prior OBD-II scanner reading experience to examine the freeze frame data and determine the problem.

4. Bad Fuel Economy

Your engine won’t perform as effectively or as efficiently as it did in the past as a result of having a subpar EGR valve. You’ll notice an increase in gasoline usage as a result. This is true because your engine has to work too hard to make up for the EGR’s shortcomings.

The engine will need to pump more fuel into the system to proceed with a successful ignition in this scenario. Or, it can result in a significant amount of fuel going unburned. It will continue to consume far more fuel than it did previously. Although this symptom may also be related to a variety of other problems.

5. While Driving, the Car Stalls

Faulty EGR valves cause your engine’s combustion to be interrupted, a pattern that is all too familiar. Your engine can stall in the worst-case scenario if it can’t properly ignite. This will typically occur more while you’re idle than while you’re driving.

The engine has to work harder to receive oxygen when it is idling or moving at very low speeds, similar to rough idling. Stalling is the worst sign of an ailing EGR valve, in our opinion. Don’t delay an immediate EGR valve repair if this occurs to you.

6. Car Feels Rough When Idle

An obvious warning indication that an EGR valve replacement may be necessary is a choppy idle. This unstable idling frequently results from an improper air-to-fuel ratio during combustion. Once more, this can be brought on by a malfunctioning EGR valve.

It is more obvious while you are idling than when the vehicle is moving how rough idling is. As the EGR valves suffocate it off all oxygen, the lower your engine load, the tougher it will be to keep it going.

7. Engine Overheating

As previously indicated, adding exhaust gas to the air intake lowers the operating temperature of the engine by reducing the amount of oxygen present. The operating temperature of the engine may be impacted if the EGR valve is broken.

Typically, this occurs when either the EGR cooler malfunctions or the EGR valve becomes stuck shut. The engine cannot lower the amount of oxygen in the combustion chamber if the EGR is jammed closed. Overheating arises from a greater combustion temperature caused by this.

To lower the temperature of the exhaust gases, the EGR additionally features a cooler. This aids in further lowering the combustion temperature, which eventually lowers emissions. The engine will overheat if the cooler malfunctions and the exhaust gas mixes with the air at a higher temperature.

Engine knocking is frequently a symptom of this overheating. Pre-detonation of the fuel and air combination, brought on by an excessively high intake air temperature, results in this knocking noise.

Naturally, there are a ton of reasons why your engine could be overheating. If none of the other symptoms on this list are present, you may have a cooling system issue.

8. A Check Engine Light Comes On

When the ECU discovers a problem that it cannot resolve, the check engine light comes on. There are numerous sensors throughout your car that provide the ECU with a variety of data. The ECU then uses that knowledge to regulate several variables, including ignition timing, fuel injection, and airflow, among others.

A check engine light by Wikiuser100000 / CC BY-SA 3.0. The check engine light turns on when the ECU encounters a problem it cannot fix. One of these issues that could set up the check engine light is code P0405.

The ECU will make certain adjustments to try to fix the issue when one of the sensors provides an incorrect reading. A Diagnostic Trouble Code (DTC) will be recorded in the onboard diagnostic (OBD) system of the vehicle if the issue continues.

The check engine light—or additional warning lights, depending on the problem—will then turn on, as a result, alerting the driver that something is amiss and needs to be fixed. And the EGR valve does indeed have sensors.

The ECU will detect a problem with the EGR valve and turn on the check engine light. Even though we all fear the amber light turning on, it will assist identify the issue and make troubleshooting much simpler.

What are Some P0405 Code Causes?

A faulty EGR valve position sensor should be the first thing to look for when investigating the P0405 code problem. A faulty or damaged EGR valve or a circuit issue that affects the EGR sensor could potentially be the problem.

The P0405 error can also be brought on by corroded or damaged wires, as well as grounded or shorted lines. The return wire to the EGR sensor may also be the source of the problem, which requires attention.

This issue code is caused by a broken Exhaust Gas Recirculation (EGR) Sensor or one of its components in your car. Your car may also record this code if the EGR system is experiencing several issues. The most typical of these are as follows:

- Faulty position sensor for the EGR valve

- Defective EGR valve

- Obstructed or blocked EGR pathway

- A faulty sensor for differential pressure feedback EGR (DPFE)

- Faulty EGR volume control solenoid valve

- Carbon accumulating on the EGR valve

- Opened or shorted EGR volume control solenoid valve harness

- Faulty electrical connection at the EGR volume control solenoid valve circuit

- Faulty EGR temperature sensor and circuit

- Broken or loose terminals pointing at the PCM

- Faulty or damaged vacuum line

Is the P0405 Code Serious?

If the P0405 problem is ignored for a long time, it may get worse. The PCM might completely shut off the EGR system, which would have an impact on how your car runs and possibly cause a rough ride.

Because of this, it’s important to check the EGR system to make sure it’s functioning properly. You run the risk of further harming your intake system and engine internals if you put off fixing the problem. Instead, you should bring your vehicle to a licensed repair facility to have a skilled technician inspect it.

The exhaust pipe of a car by Alexander Migl / CC BY-SA 4.0. The strong gasoline smell coming from the tailpipe when you have the P0405 code is caused by high levels of hydrocarbons being released into the exhausts and out of the tailpipes.

Can I Drive After Getting a P0405 Code?

Driving while having a P0405 error code will put more strain and stress on your engine because it won’t be running at its best.

Your engine’s EGR system is essential to its smooth operation, so you shouldn’t put it in danger by continuing to drive it in challenging conditions. Take your car to a qualified mechanic right away to have it inspected if you notice your engine starting to ping.

How Simple Is a P0405 Code Diagnosis?

A technician will start the P0405 code’s diagnostic procedure by scanning the PCM’s stored codes and any available freeze frame data. After trying to erase the codes, they’ll run a road test to see if they come back.

The conditions in the engine at the time the PCM triggered the P0405 code will then be attempted to be evaluated using the freeze frame data. The EGR sensor on the scanner will then be examined by the technician to determine whether it shows that the EGR valve is positioned correctly.

Before examining the EGR sensor’s physical state, they will also check to see if it is reading a low voltage. In addition, the technician will attach the reference voltage sensor and signal return pin and check the readings. Finally, the wiring and connectors leading to the EGR sensor will be physically inspected.

How Hard Is It to Examine a P0405 Code?

EGR valve and EGR position sensor conditions will be evaluated as part of the P0405 inspection process. Both of those components will need to be replaced if one of them is faulty or broken.

Since this process necessitates a great deal of attention and testing, a technician is the most suitable. They advise against performing this at home because you run the risk of misdiagnosing the problem’s cause and end up doing more harm to your engine.

A technician will also check and keep an eye on the voltage leaving the EGR system and fix any vacuum leaks that are already present. Finally, they will visually check the EGR system wiring, repair any corroded or damaged wires, and make sure all connections are strong and secure.

What Fixes are Available for the P0405 Code?

Depending on what caused the issue, several fixes can remove the P0405 error code. Complete diagnostics must be run first to make sure you understand the issue. Here are a few potential answers.

- Replace the EGR valve if necessary.

- Replace the EGR position sensor if necessary.

- EGR position sensor cleaning

- Check the EGR system’s voltage.

- Be on the lookout for an EGR system vacuum.

- Repair any discovered vacuum leaks.

- Check for loose connections and make sure the connection is secure by visually inspecting the wiring leading to the EGR sensor.

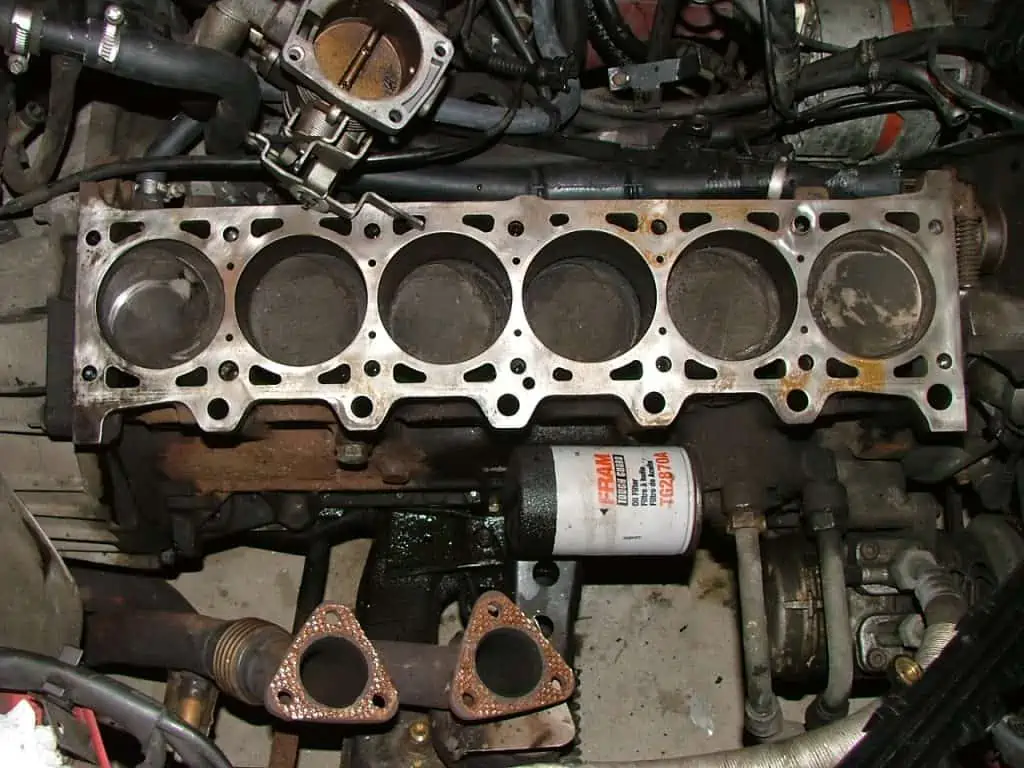

A car engine block by Kether83 / CC BY 2.5. A poor EGR valve that triggers code P0405 will prevent your engine from operating as effectively or efficiently as it did in the past.

The Estimated Cost of Repairing P0405 Code

P0405 stands for “Exhaust Gas Recirculation Sensor Circuit A Low” in a diagnostic trouble code (DTC). Numerous things can cause this, so a mechanic must identify the precise cause in your case to clear the code.

For $114.99, qualified mobile mechanics will visit your house or place of business to run the check engine light diagnostic. You’ll get an upfront estimate for the suggested fix as soon as they can identify the issue.

Some of the costs you might incur are listed below.

- $0-$150: Repairing the EGR position sensor wiring

- $100-$150: Replacing the EGR position sensor

- $150-$500: Replacing the Differential Pressure Feedback Electronic (DPFE) sensor

- $75-$150: Checking the PCM connection/updating software

- $400-$1,300: Replacing the PCM

Diagnosing the P0405 Problem Code

When you have had a similar experience, this diagnosis may be do-it-yourself. To read the freeze frame data and make a diagnosis, you must have prior OBD-II scanner reading experience.

You need a specific Electric Vehicle Diagram (EVD) that matches the make or model of your vehicle to successfully diagnose your car for this error code. Additionally, a Digital Multimeter (DMM) and an OBD-II scanner are required to scan and read the freeze frame data.

It is significant to remember that an OBD-II scanner is typically advised for this diagnosis. However, if the OBD-II scanner is not available, a DMM can be utilized. Before you start the diagnosis, make sure your car battery charger is connected while these tools are on standby.

- Connect the OBD-II scanner and download the freeze frame information for the EGR first.

- Next, visually examine the wire connections to look for burns or damage.

- Additionally, check for potential pin breaks and water damage, and fix any discovered damages to the connection.

- Continue by visually inspecting the EGR sensor connector and looking for corrosion.

- Examine the EGR position sensor next. If the EGR valve on your car is vacuum-actuated, you must use a vacuum pump and DMM to test the position sensor.

- After that, take out the connector and measure the resistance throughout the entire circuit. You should receive approximately 6kΩ as the reading.

- Use the DMM to scan the connector on the back of the electronically activated EGR and record the output voltage. During this procedure, make sure the car’s engine is off and the key is turned on.

- A short circuit or a damaged sensor is present in this system if the voltage deviates from the PCM’s specifications.

- If a repair is unsuccessful in repairing the damage, replace the circuit and sensor.

- After completing the aforementioned steps, clear the code and put the car through a test drive to see if the error code reappears.

- If the error code reappears, use the OBD-II scanner to view the EGR sensor PID (Performance Information Data), and determine whether the sensor indicates that the valve is properly closed or the sensor voltage returns below specifications.

- Connect the sensor reference voltage and the signal return pins, then check the scanner to see if the EGR sensor PID reference voltage is displayed.

- Last but not least, swap out the EGR sensor or fix the wiring as necessary, then recheck the system for accurate readings.

A power-train control module by Mgiardina09 / CC BY-SA 3.0. The EGR valve’s location is determined by the EGR position sensor. The powertrain control module (PCM) monitors and adjusts EGR valve operation using the sensor signal. If the sensor’s signal seems particularly weak, the PCM might set a P0405 code.

P0405 Code: Common Diagnosis Errors

People frequently replace components even when they are not broken. Before you replace the EGR position sensor, it is crucial to inspect the wiring harness and connection. An open circuit or simple short circuit could be the issue.

Additionally, you ought to examine each wiring. Before you replace the EGR position sensor, you should check these easy problems.

Associated Codes to P0405

This error code has connections to other EGR-related codes, such as;

- Exhaust Gas Recirculation Flow Malfunction: Code P0400

- Exhaust Gas Recirculation Flow Insufficient Detected: Code P0401

- Exhaust Gas Recirculation Excessive Flow: Code P0402

- Exhaust Gas Recirculation “A” Control Circuit Malfunction: Code P0403

- Exhaust Gas Recirculation Circuit Range/Performance: Code P0404

- Exhaust Gas Recirculation Sensor A Circuit High: Code P0406

A Mechanic’s Advice Relating to the P0405 Code

When the EGR sensor or differential pressure feedback electronic sensor malfunctions, many of the same symptoms may appear. To avoid ending up in the same predicament, you must conduct the proper diagnostics and carry out the necessary repairs.

DPFE and EGR Sensors

Early Ford with fuel injection had a vacuum solenoid and a three-wire linear EGR Valve Position (EVP) sensor that detected movement of the diaphragm. Monitoring the pintle position, however, does not demonstrate that EGR gas is entering the intake.

Because the inert exhaust gas entering the intake displaces oxygen, GM vehicles (pre-OBD2) will monitor O2 sensor activity while the ECM is ordering EGR flow. This is because O2 sensor readings will slightly drift richer during this time.

A different feedback system with a 3-wire pressure sensor was created by pre-OBD2 Ford engineers and debuted in 1991 on Lincoln Town Cars.

The EGR feed pipe is connected to that sensor by two silicone hoses, each with an orifice in the middle. The “DPFE” sensor stands for Delta Pressure Feedback EGR, according to Ford. Fords with EGR from the OBD2 era still had that system.

When EGR is flowing on a Ford, the pressure in the hose attached below the orifice in the EGR feed pipe will rise, and the pressure in the hose linked above it will drop, allowing the sensor to determine whether or not EGR is flowing, as well as how much.

This sensor has three wires (5V, Signal Return ground, and Signal). On metal DPFE sensors, the signal wire rests at about 0.6 volts, while on plastic ones, it rests at about 1.0 volts. The P0405 code is set if this sensor voltage reads lower than the predicted window.

The Conclusion

When the EGR position deviates from the PCM specifications, DTC Code P0405 is recorded. Nevertheless, if you have a reliable OBD-II scanner and follow the step-by-step directions to troubleshoot the code, this problem can be cleared without the assistance of a skilled technician.

If you’re a novice, it could be safer to have an expert make the diagnosis. Additionally, allowing this code to remain in your car without being fixed could cause other issues and potentially cause your car to record another code. In conclusion, regardless of the severity, we advise that you pay close attention to every OBD-II.

Electronically actuated EGR Valve by Towel401 / CC BY-SA 4.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”