As you approach your house to turn around and park your car, you begin to hear a clunking noise when turning. To be honest, this is horrible news. But fortunately for you, there is a lot to cover on this subject and you are in the correct place.

Any sounds or symptoms coming from your car should raise a red flag for you as the owner. How come this is the case? This is true since unusual noises frequently signify a problem. These issues can become considerable.

While other times, these issues merely serve to annoy you. as while turning, there is a clunking sound. You must look into it before you can determine why it appears.

Because of this, troubleshooting is necessary here. How then do you troubleshoot? By itself, troubleshooting requires mastery. You must comprehend how components function and interact with one another to troubleshoot.

Knowing this will enable you to identify the issue. You must therefore develop your problem-solving skills so that you can avoid employing expensive technicians to fix your difficulties. But I’ll get to that later.

What is crucial is that we will discuss a clunking noise when turning in this essay. After that, we’ll talk about the causes of the clunking noise when turning in the first place.

After that, we will discover how to identify the problem and how much it will cost to correct the clunking noise when turning. So, keep reading if you’re eager to learn more.

A Clunking Noise When Turning: What Is It?

When your vehicle makes a clunking noise when turning, it is telling you that there is a problem. It informs you that your car has a problem. Although this noise may not be overt, it can nonetheless be very annoying and hard to cope with. What makes me say this?

Consider that there are ten corners you must travel till you arrive at your business. You will fear that the car will crash ten times during the journey. Believe me, it can.

A typical ball joint by Silverxxx. Ball joints that are worn out are one of the main causes of any form of turning noise. When you enter a corner at a high speed while losing control, the tires squeal.

Particularly if there is something loose underneath, and in the worst-case scenario, you can end up without a wheel. If the wheel comes off, it can even overtake you, leaving your car on the ground and severely damaged.

And that’s not what you want. You don’t want your car to get wrecked and ruined. The cost of fixing this damage could go into thousands of dollars.

And a ball joint was the main cause of this issue. It costs only about $5 for the part. So be on the lookout for the clunking noise when turning and don’t dismiss this problem as soon as it starts.

You must therefore develop troubleshooting skills. Mastering troubleshooting calls for solid knowledge of mechanics and how things operate.

You must study how the components interact with one another and how to spot underperforming components. Afterward, determine which of these parts may have failed based on the symptom of clunking noise when turning.

You shouldn’t worry, though, since we’ll show you how to do it in the chapters that follow, where we’ll discuss some of the potential causes of the clunking noise when turning.

Why Do I Hear a Clunking Noise When Turning?

You can solve these problems, as we already said. You must first educate yourself on the potential sources of this issue. Without a foundation, a house cannot be constructed.

That is not how things operate. You first become aware of the causes and implications of the clunking noise when turning issues. The next step is to diagnose the problem.

Let’s now examine the causes of the clunking noise when turning issue. Then, if you have the skills, we’ll look at how to identify the problem and make a repair. So, keep reading if you want to learn.

1. Outdated Ball Joints

One of the main reasons for any kind of turning noise is worn-out ball joints. The tires screech when you hit a turn at a high speed when they are out of control. Comparable to vintage Hollywood productions from the 1970s and 1980s.

The severity of these ball joint issues is best seen in automobiles with extreme body roll. Specifically, trucks, SUVs, etc. You get the picture. But what function do the ball joints serve?

The ball joints’ function is to attach the control arm to the wheels. Cars only have one control arm, the lower control arm, compared to the two control arms seen on large trucks and SUVs. At the point where the control arms link to the wheel hub assembly, ball joints are present.

The rubber cover that protects the ball joints has lubrication on it and eventually fractures due to brittleness. When dust gets inside, chaos occurs. It results in greater ball joint wear and tear and calls for replacement. Therefore, examine these ball joints if you experience a clunking noise when turning.

2. Broken Tie Rods

Tie rods also deteriorate over time and need to be changed. On either end of the steering rack, these tie rods are placed. They are two on each side, according to this. There are two tie rods: an inner one and an outer one. These parts aid you in turning the car around a corner. They are attached by screws to the steering rack and, in turn, the wheel knuckle.

The lower tie rod bar by Jpogi / CC0. Tie rods must be replaced since they degrade over time. These tie rods are mounted on the steering rack’s ends. This means that there are two of them on each side. One inner and one exterior tie rod are present. These components help you maneuver the vehicle around a corner. They are fastened to the steering rack, which in turn is fastened to the wheel knuckle, via screws.

What’s worse is that these parts are aware of the wear and can result in sounds like a clunking noise when turning.

They also have lubrication, and as this lube starts to wear off, they begin to wear out too quickly and develop symptoms and issues.

The fact that they are reasonably priced and affordable to replace is a plus. They are also simple to inspect to see if they need to be replaced because they are damaged. But I’ll talk more about that later.

3. Sway Bar Link Damage

Sway bars are added in body-on-frame automobiles of an older design. The purpose of these sway bars is to lessen the vehicle’s body roll.

Every car experiences body roll when turning. Therefore, the sway bars connecting the vehicle’s two sides keep it from moving around and causing you to lose control.

Modern vehicles don’t have sway bars because they have independent suspensions. However, some automobiles, such as pickup trucks and SUVs, continue to use them. What’s worse is that these sway bars feature sway bar linkages connecting the knuckle to the sway bar at both ends.

comparable to other suspension parts. The years and miles have lubricated these links. These connections begin to break down and have problems. In particular, the clunking noise when turning.

If you experience such a condition, you should get started on the diagnosis right away. But once we discuss all the potential factors that could contribute to the occurrence of this issue, more on that.

4. Damaged Control Arm Bushings

The wheel is secured to the car’s chassis via the control arms. Your wheels will come off and your car’s underside will be ruined without a control arm.

In earlier applications, control arms are made of high-strength steel and are incredibly durable. Modern automobiles are built of aluminum with exceptional strength. It’s also important to note that the lower control arm of current automobiles is the sole remaining control arm.

Classic cars, trucks, and SUVs are still examples of vehicles with two control arms. The bushings, though, are what matter in this case. The bushings, on the other hand, wear down more quickly than the control arms.

Typically, each control arm has three high-strength plastic bushings, one for each hole, which is installed. The control arms are then secured in place with large screws that ensure their strength.

However, the fact that these bushings deteriorate with time is terrible. particularly if the vehicle is older than 20 years. Consequently, the clunking noise when turning was brought on.

You can swap them out or replace the control arm as a whole. It is better to replace the control arms because they are reasonably priced than to hire someone to take out the old bushings and replace them.

An automotive anti-roll sway bar by Stahlkocher / CC BY-SA 3.0. In older-style body-on-frame cars, sway bars are added. These sway bars are designed to reduce body roll in the vehicle. When turning, every car undergoes a body roll. Sway bars that connect the vehicle’s two sides prevent it from moving and letting you lose control as a result.

5. Broken CV Joint

A CV joint is a component seen in contemporary cars. Unlike earlier systems, which employed solid axles. Greater flexibility is provided by the CV joint, which also improves pothole absorbency by allowing the wheel to move more freely.

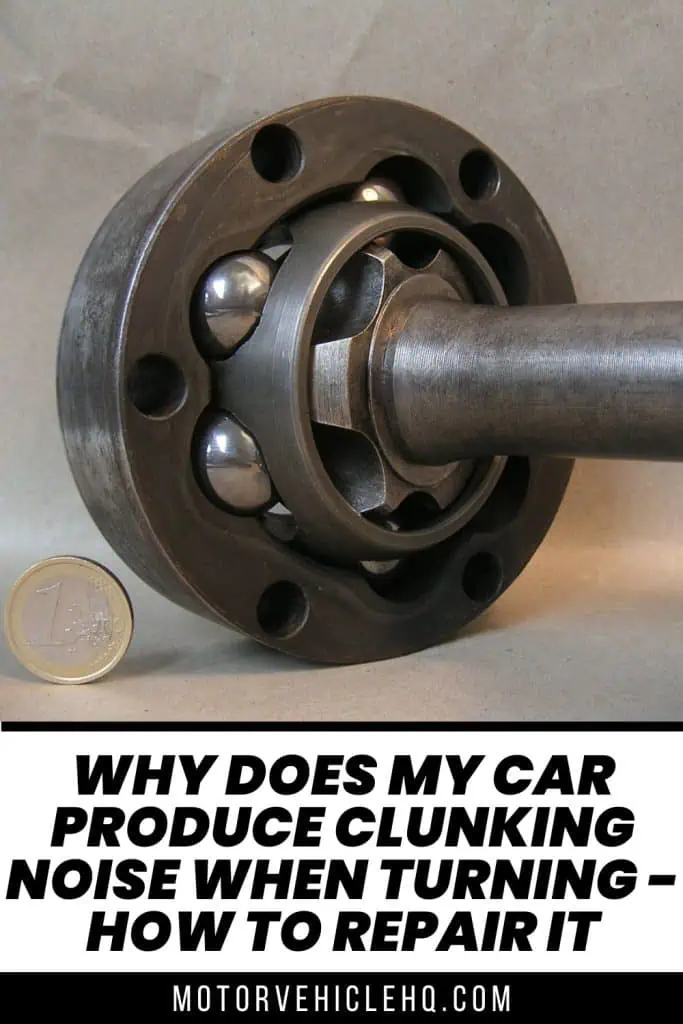

These CV joints have an inventive design that consists of rods connected by bearings. Although this design has been around for millennia, the CV joint was where it first saw widespread use.

However, these CV joints are protected by rubber boots. And as time passes, they begin to fracture, allowing dust and other contaminants to penetrate the interior. causing a clunking noise when turning and causing the bearings to wear out too soon. Squeaking is another sound that is frequently associated with this issue.

The best course of action in this situation would be to completely replace the old CV shaft with a new one. They are also reasonably priced. each costing between $150 and $250. If you want to update your suspension, it is preferable to replace them both.

6. Wheel Bearings are Worn

Additionally, worn-out wheel bearings frequently create a whining or clunking noise when turning noises. What, though, is a wheel bearing? Your car can roll freely thanks to a wheel bearing.

The knuckle has wheel bearings put on it. Numerous steel balls that have been specially lubricated make up the bearings of these machines.

These bearings begin to malfunction and fail when the car has a lot of kilometers on it. When you increase your speed, a whining sound will first become audible. But clunking will also be present if the bearing fails.

It is important to note that the clunking noise when turning is rarely caused by the wheel bearing. However, if nothing fixes your issue. Make sure the bearing is in good condition as a last resort.

You can accomplish this by wriggling your wheel while it is in the air. if games are present. Your best option would then be to replace it.

7. Broken Struts or Damaged Strut Mounts

The struts may malfunction and result in havoc. What makes me say this? This is true since your entire suspension is supported by the strut. You will first notice some clunking noise when turning if the strut fails.

Struts fail to stop the car from rolling, but even worse, their mounts may also fail. The strut and strut tower are connected by the mount. Throughout their lives, these mounts take a lot of punishment.

They also develop a play as they get older, which can cause symptoms like clunking noise when turning and a “grinding noise.” heavily dependent on the vehicle.

It is frequently suggested that you inspect the struts for damage if you hear this sound. This is your initial assignment. If they are, you must change them. If they aren’t, look at the mounts; if they’re damaged, just replace the mounts.

And you’ll be all set to go. When you don’t have to, why pay a lot of money? This will ensure that the clunking noise when turning is eliminated.

The Rzeppa constant velocity joint by Nutzdatenbegleiter / CC BY-SA 3.0. A CV joint is a part found in modern automobiles. Earlier systems used solid axles, but not anymore. The CV joint offers increased flexibility, which enhances pothole absorption by allowing the wheel to move more freely.

8. Defective Power Steering Rack

One further component that could break down and cause your automobile to create a clunking noise when turning is the power steering rack. The power steering pump’s failure may also cause this to occur.

When you move the wheel, the hydraulic fluid is pushed by the power steering rack, which causes the wheels to turn in the opposite direction.

Even worse, these steering racks are conscious of their propensity to malfunction and cause issues. Clunks when turning, give the impression of winning. These noises almost always indicate a damaged steering rack.

Additionally, oil seeps onto the steering rack when the rack fails. The broken seal on the power steering is what’s causing these fluid leaks.

Unfortunately, the cost of these power steering racks makes them unaffordable. For a steering rack alone, you might have to fork over up to $500 or perhaps more. Additionally, the cost of installation is high.

9. Damaged Spring

A clunking noise when turning may also arise if the spring breaks. But this is uncommon. One out of a million times, yet there is still a chance that it could occur and leave you with this issue.

You can get through this stuff if you drive a truck. Consider a situation where the truck is overloaded and the springs receive significant weight. In this instance, sounds are audible.

in particular, clunking noise when turning. Enough about the causes of this clunking noise when turning, though. Let’s talk about how to identify the issue.

10. Defective Rear Differential

The rear differential is one of the more difficult problems you might encounter. It can be expensive to replace, however, the differential may have several worn parts. Howling, whirring, or other noises while cornering are signs of a faulty differential and should be corrected.

You will need assistance because diagnosing or handling this problem can be difficult. The ideal method would be to elevate the automobile while someone is on the accelerator to observe what is happening while it is moving.

You will be able to detect potential problems more clearly and inspect each component as a result. A trip to your neighborhood mechanic would be a better choice.

11. Outdated Shocks

You will put a lot of stress on your shocks if you prefer driving on uneven terrain. Your shocks will eventually break down as a result of the added stress.

The problem might not be obvious when turning, but you will hear the clunking sound when turning on uneven roads or when scaling pumps.

Fortunately, replacing shocks is yet another simple task for you. Not much work is required, and the component may be extremely affordable as well.

By simply jacking up the car, you can access your shocks and replace them at home. This will guarantee that you can operate your car efficiently.

A typical wheel bearing by Solaris2006 / CC BY-SA 3.0. Wheel bearings have been installed on the knuckle. The bearings of these machines are composed of a large number of steel balls that have been properly greased. When the car has a lot of miles on it, these bearings start to malfunction and fail. You’ll first hear a whining sound when you pick up the pace. But if the bearing fails, there will also be clunking.

12. Rusted Ball Sockets

The car needs the ball sockets in the back end to turn and move around with agility. These parts, however, could wear out just like any other component of your car.

Once they are worn, you could hear a grinding or clunking sound when you turn your car. It can be because of the worn ball sockets.

Fortunately, replacing this item won’t cost much, and you’ll need to do it for both link assemblies.

Although it might sound difficult, you only need to jack up the car on either side to get it in the air so you can access the parts. You may easily accomplish this at home if you have the necessary equipment.

Only When Turning on One Side Does the Car Make Noise?

The problem is most likely limited to the tie rods, suspension struts, CV joint, or wheel bearing if the automobile makes noise when turning right but not left or left but not right.

Unilateral noise can be caused by any component in an automobile that has two or more of them if either the left or right is broken.

Remember that both sides can fail at the same time. Even though it is quite rare, there might have been a driving incident, such as driving into a large pothole, that resulted in damage to both sides.

Is the Steering Wheel Affected By the Problem?

Identifying whether the issue creating the sound also affects the steering wheel is a crucial piece of the puzzle.

When there is turning noise in addition to a steering wheel issue, the issue is most likely limited to the power steering system, faulty struts, ball joints, tie rods, or wheel bearings.

Does the Noise Vary with Speed?

While stationary and twisting the steering wheel can pick up some sounds, others are best heard while moving on the highway.

Only issues with the power steering, steering column, ball joints, tie rods, or control arm bushings can cause a noise to be heard while the car is still yet the steering wheel is rotating.

Wheel bearing, CV joint, or other suspension strut failure is typically the cause of noises that occur during turning and driving in.

How to Diagnose Clunking Noise When Turning: A DIY Approach

Now let’s go to work and identify the cause of your car’s clunking noise when turning and suspension issues. You will require some jack stands for this task to lift and secure the front end.

This is only necessary if you wish to conduct a thorough inspection. If not, there will be enough to lift the wheel for inspection.

The rear differential by Dana60Cummins / CC BY-SA 3.0. One of the more difficult issues you can run into is the rear differential. The differential may have multiple worn parts, but replacement might be expensive. When a vehicle is cornering, howling, whirring, or other noises are warning signals of a bad differential and should be fixed.

The wheel’s condition should be checked by lifting the car. The wheel should be moved a bit to the left and right.

This will provide you with a wealth of information on the wheel bearing located inside the wheel assembly. if it is frequently played. The wheel bearing must then be changed.

The ball joints should also be examined. Examine how they are doing. The rubber will need to be replaced if it is worn out and greasy. The CV axle is the same.

Verify the condition of the boots. The CV axle is likely damaged if they have started to leak and the rubber boot is not in the proper position. It’s fine if it’s nice and dry.

The control arm comes next in the process. You must look for leaks in the bushings to inspect this. The likelihood of having to replace them increases if they are leaking.

Additionally, some vehicles still use bushings from a previous era without oil. So, inspecting these entails assessing their state and checking to see if they have dry rot.

Don’t forget to remember the steering rack as well. Make sure the underside is completely dry. You’re good if nothing is wet and there isn’t a play. Replace the broken pieces if necessary.

A Clunking Noise When Turning: How Much Does It Cost to Fix?

If your steering rack isn’t broken, the cost to correct clunking noise when turning problems is fairly modest. Typically, bushings and ball joints cost a few bucks. You should budget about $250 for a new CV axle.

You will most likely spend $150 on a control arm, while wheel bearings cost only $50 to $100. The steering rack is what is pricey. It could cost you over $500 to repair one of these racks because they are fairly expensive.

However, all of the costs we listed apply if you complete the work on your own. If you choose to accomplish this in a workshop, you should attempt to address the clunking noise when turning there. Expect to pay a minimum of $100 and a maximum of $1,500.

This is true since some jobs require a significant amount of effort to be involved to resolve these issues, and not all work is inexpensive. Find a business that will perform this service affordably while still producing a high-quality outcome.

Does This Job Require Alignment After It Is Completed?

It’s crucial to understand the answer to this good question. Yes, you will require an alignment after performing some repairs on your suspension. How come this is the case?

This is true because when you swap out parts, the alignment is ruined. The new component won’t make the automobile happy. To make the wheels run precisely straight and without any hiccups, an alignment must be performed on the car.

If your vehicle is out of alignment. One of the main indications to watch for is issues like uneven tire tread wear and wheels pushing to one side. For this reason, when you remedy the clunking noise when turning, be careful to make an alignment to ensure the best possible driving experience.

Miniature oil-filled Coilover shock components by Avsar Aras / CC BY-SA 3.0. If you choose to drive on uneven terrain, your shocks will be put under a lot of strain. The additional strain will eventually cause your shocks to malfunction. Although the issue might not be immediately apparent when turning, you will hear the clunking sound when scaling pumps or turning on uneven roadways.

Can I Keep Driving the Car That Produces Clunking Noise When Turning?

You can choose to drive a junker if you want to. Your choice, but you cannot hold people accountable for not warning you if your wheel comes off in the middle of the road.

It’s critical to act as soon as you detect issues like this clunking noise when turning and attempt to find a solution. You are endangering both your life and the lives of your passengers.

The Conclusion

When it comes to the issue of clunking noise when turning, we have covered a lot in this post. First, we discovered what this issue is and what it stands for. As we previously mentioned, this indicates that there is a problem with the car’s suspension.

After then, we discussed the causes of this issue in first place. Understanding this will be a further aid in identifying the problem. The ball joints and bushings need to be carefully examined, though. These are the most frequent causes of clunking noise when turning.

Finally, we concentrated on identifying the problems and learned how to inspect these components to identify which ones are defective and need to be replaced.

The costs associated with this process were then paid for. As we mentioned, these can differ and are very dependent on the component in question. Last but not least, perform an alignment following your repair.

The Rzeppa constant velocity joint by Nutzdatenbegleiter / CC BY-SA 3.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”