The “heart” of a car is its engine. It is a sophisticated device made to transform one or more sources of energy into mechanical energy, which rotates the vehicle’s wheels.

While many of us conceive of the engine as one main part, it consists of several smaller parts that all operate together.

It’s crucial to understand the fundamental components of a car engine and their roles, even though you may be familiar with the names of some of these car engine parts.

The engine block (cylinder block), combustion chamber, cylinder head, pistons, crankshaft, camshaft, timing chain, valves, rocker arms, pushrods/lifters, fuel injectors, spark plugs, oil pan, manifold, connecting rod, piston ring, and flywheels are some of the various components that make up an automobile engine.

There are 200 or so parts in a normal internal combustion engine that require maintenance and may need to be replaced if they become worn out. With an electric vehicle, there are just about 20 pieces.

Which are the Engine’s Fundamental Components?

Even though an engine is made up of several elements, we’ve produced a list of the most crucial parts and what they do to power your car. To find out where they are on your engine, consult the diagram. The following are the essential components of a car’s engine:

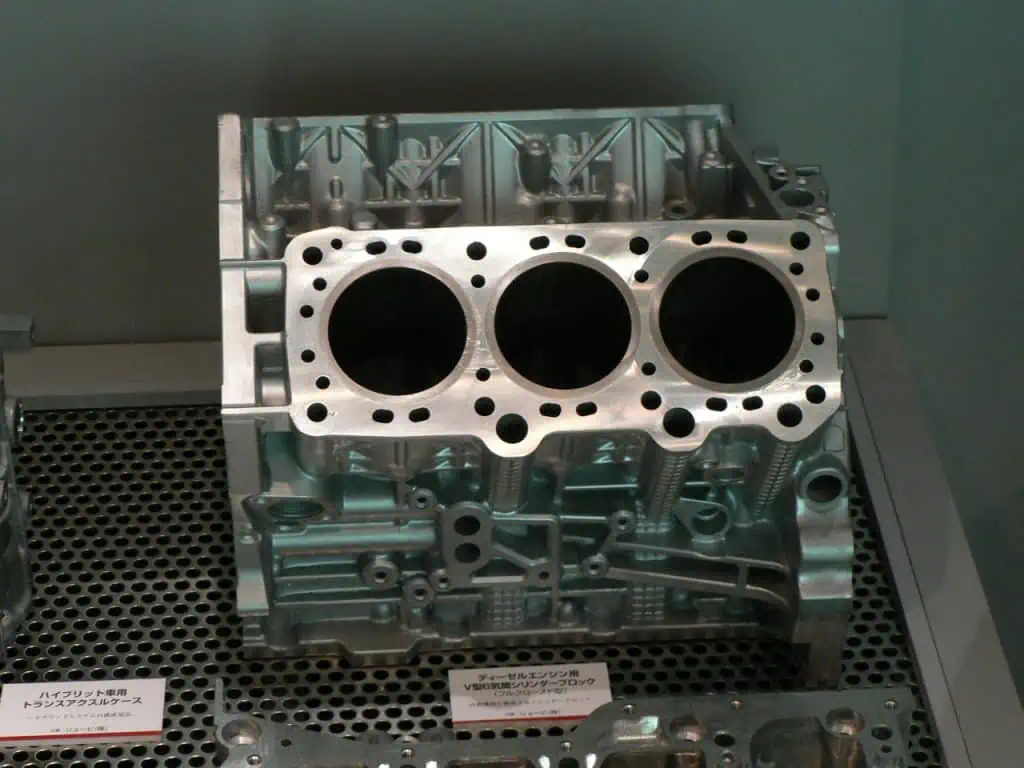

1. The Cylinder Block or Engine Block

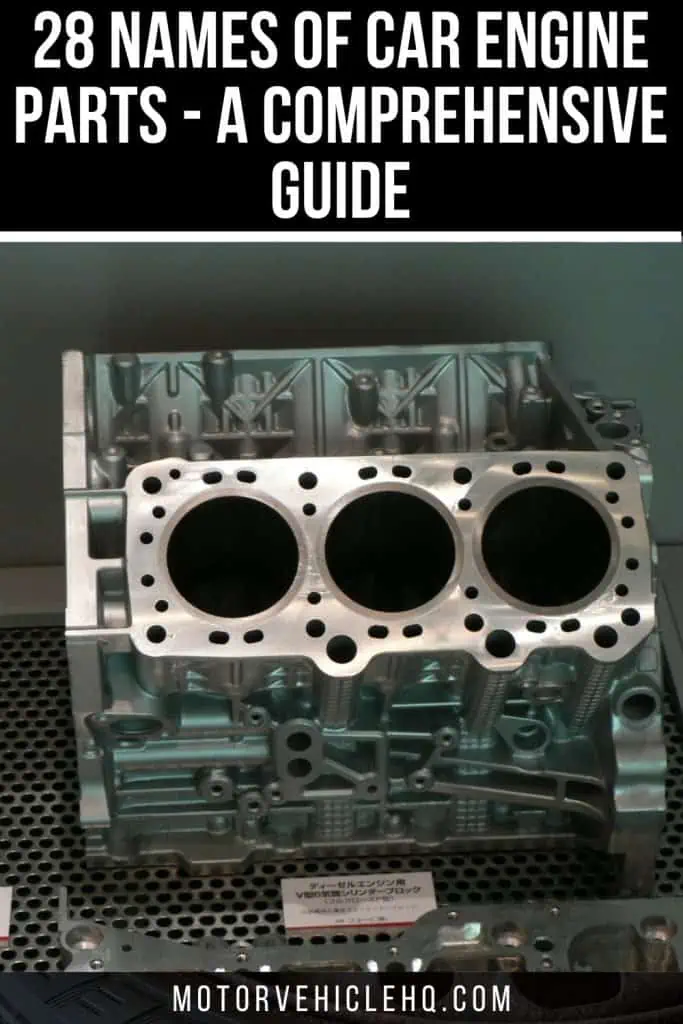

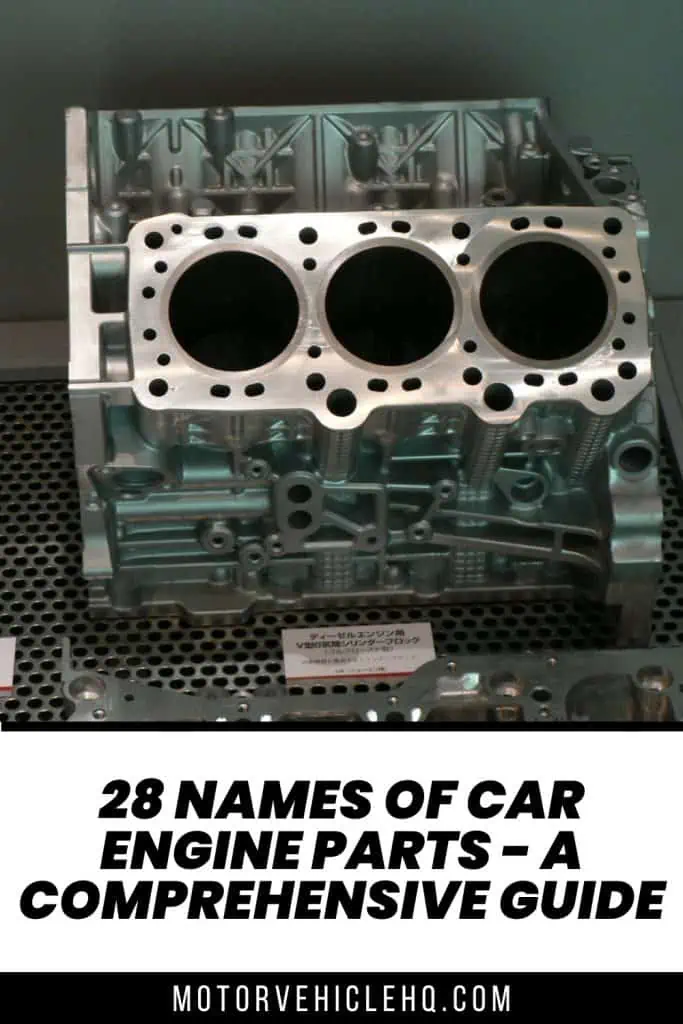

The cylinder block, often known as the engine block, is the engine’s basic structural component. is a crucial aspect of the engine parts. The engine’s construction and main stationary body are made up of three parts cylinder block, cylinder head, and crankcase.

To keep the cylinders contained and allow water and oil flow channels to cool and lubricate the engine, this engine component features several holes. It is frequently constructed from iron or aluminum. Oil flow channels are less extensive than water flow pathways.

A fully closed cylinder block by 160SX / CC BY-SA 3.0. The fundamental structural element of the engine is the cylinder block, also referred to as the engine block. a key component of the engine parts. The cylinder block, cylinder head, and crankcase are the three components that make up the engine’s structure and major stationary body.

Four to twelve cylinders are stacked in a line, commonly referred to as an inline, flat, or V-shaped layout, depending on the vehicle design. It is connected to pretty much every part of the motor. The magic, including combustion, happens inside the block.

2. The Pistons

When compared to other parts of the engine, pistons are the most crucial. A cylindrical plug that revolves inside a cylinder serves as the piston. It helps to transform the pressure energy of fuel combustion into usable mechanical power, which is then sent to the crankshaft via the connecting rod.

For each turn, the cylinder’s pistons move twice—up and down. 2500 times per minute will be up and down in engines with piston velocities of 1250 RPM. Piston rings are a component of the piston that serve to both boost compression and decrease friction from the piston’s constant rubbing against the cylinder.

3. The Cylinder Head

The cylinder head is usually made of cast iron and an aluminum alloy. The cylinder head and block, which are joined by studs affixed to the block, use gaskets to provide a tight, leak-proof seal.

The cylinder head of each engine has a combustion chamber above each cylinder. It also contains threaded holes for valve guides, valve seats, ports, and coolant jackets in addition to threaded holes for spark plugs. It has channels where cooling water can circulate.

The head gasket isolates it from the engine by sealing it against the cylinder bolts. A few of the parts in the cylinder head that control the channels that permit intake airflow into the cylinders during the intake stroke include the valve springs, valves, lifters, pushrods, rockers, and camshafts. There are exhaust channels as well, which are used to remove exhaust gases during the exhaust stroke.

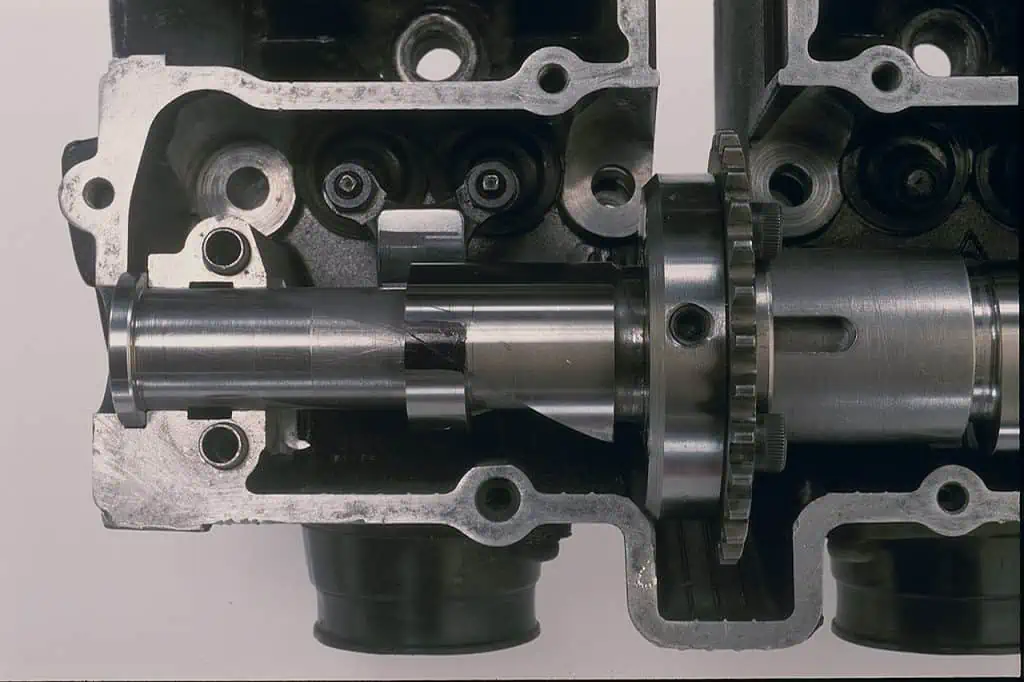

4. The Crank Shaft

The crankshaft is the component of the engine that generates power. It serves as one of the main means of power transfer for all engine components.

The crankshaft is the primary part of the power transmission system where the reciprocating action of the piston is converted into a rotational motion with the help of a connecting rod.

A piece of heat-treated alloy steel that has been cast or forged makes up the crankshaft. This component consists of crankpins, weds, a balancing weight, main journals, and oil holes.

The crankpin on the crankshaft is connected to the big end of the connecting rod. The distance between the crankpin and the crankshaft’s center makes up half of the piston’s displacement during the stroke.

At the lowest point of the engine block, the crankshaft is located inside the crankshaft journals (an area of the shaft that rests on the bearings).

This perfectly designed and balanced apparatus is attached to the pistons by the connecting rod. The crankshaft transforms the piston’s up-and-down motion into a reciprocal motion at engine speed, resembling a jack-in-the-box.

5. The Camshaft

A camshaft is a shaft that has cams mounted on it. A cam is a piece of machinery that transforms the rotational action of the camshaft into the linear motion of the follower. A camshaft opens the valves when it operates.

This section of the car’s engine has several cams running the length of it, two for each cylinder, one for the intake valve, and one for the exhaust valve. An eccentric for the fuel pump and gear for the oil pump and ignition distributor is also found on the camshaft.

A shaft with mounted cams is referred to as a camshaft. A cam is a piece of equipment that converts the camshaft’s rotational movement into the follower’s linear motion. When it works, a camshaft opens the valves.

The camshaft is driven by the crankshaft. The number of teeth on the crankshaft gear is half that of the camshaft gear. Camshafts are made of alloy steel.

The function of the camshaft is to change the rotational action of the crankshaft into an up-and-down motion that regulates the movement of the lifters, pushrods, rockers, and valves. Additionally, it regulates when the valves open and close.

Depending on the vehicle, the camshaft could be in the cylinder heads or the engine block. They go by the designations Dual Overhead Camshaft (DOHC) or Single Overhead Camshaft and are found in the cylinder heads of many modern cars (SOHC). They are held up by several long-lasting bearings that are greased with oil.

6. The Case Crank

In two-stroke engines with a crankcase-compression setup, the fuel/air mixture frequently passes through the crankcase before entering the cylinder (s).

This engine’s design does not include an oil sump in the crankcase. In four-stroke engines, the crankcase, which often has an oil sump at the bottom, houses the majority of the oil.

The crankshaft is contained in a crankcase of an internal combustion engine that is reciprocating. In the majority of contemporary engines, the crankcase is a part of the engine block.

Even though the fuel/air mixture does not flow through the crankcase in a four-stroke engine, a tiny amount of exhaust fumes frequently enter the crankcase as a “blow-by” from the combustion chamber.

Although the crankcase often forms the bottom half of the main bearing journals in engines, the crankcase occasionally completely encircles the main bearing journals in other engines (with the bearing caps comprising the other half).

7. The Timing Chain or Timing Belt

In a piston engine, either a timing belt (sometimes referred to as a cambelt), timing chain, or a set of timing gears are used to synchronize the rotation of the crankshaft and camshaft.

This synchronization allows the engine’s valves to open and close in proportion to where the pistons are located at the right times.

Additionally, an interference engine’s timing belt or chain is crucial for preventing piston-valve contact. A timing belt often refers to a drive belt with teeth on the internal surface. A timing chain is a roller chain.

Gears on a belt made of durable rubber grasp the camshaft and crankshaft pulleys. The chain features teeth that it utilizes to wrap around pulleys, much like a bike chain.

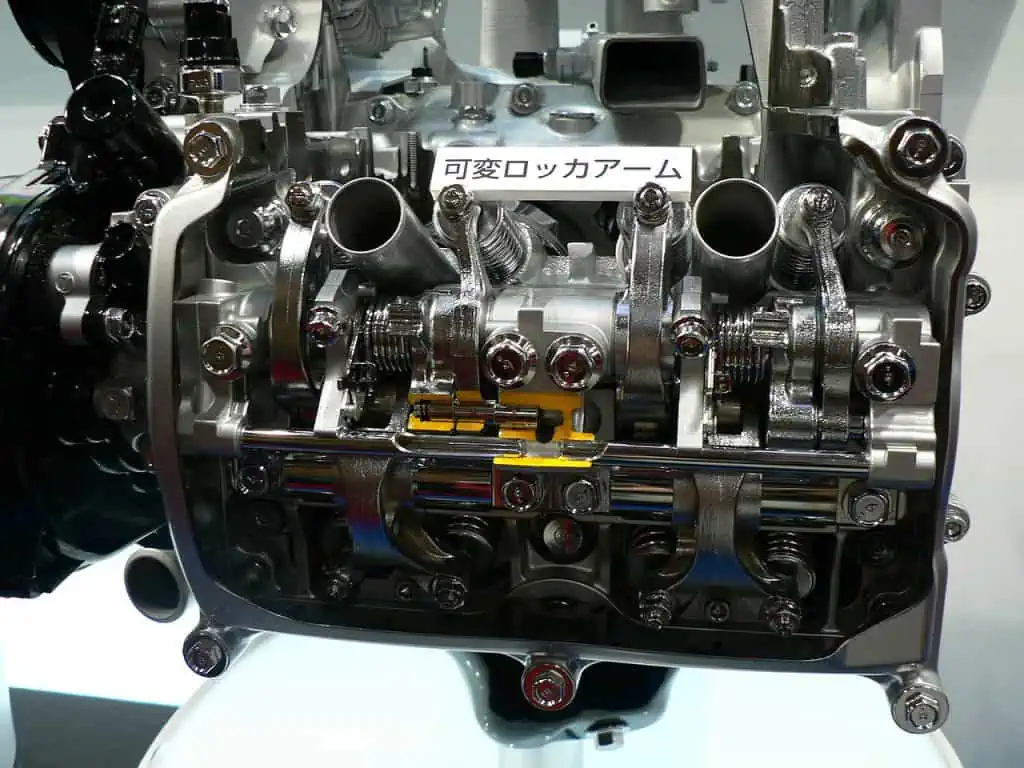

8. The Engine Valves

Engine valves are required to control when the air-fuel combination enters the cylinder and when combustion products leave the cylinders. These are located at the intake and outlet holes of the engine cylinder. The valves are snug against the valve seats when they are closed.

These auto engine components also function as mechanical valves that regulate the flow of fuel, air, and exhaust gases into the combustion chambers or cylinder heads when the engine is running.

The variable valve timing system by 160SX / CC BY-SA 3.0. The timing of when the air-fuel mixture enters the cylinder and when combustion products exit the cylinders are controlled by engine valves. These are found at the engine cylinder’s intake and output apertures. When the valves are closed, they are snug against the valve seats.

The valves open to allow the flow of gases and then close as a result of the force of the spring. They operate in this way. In opposition to the spring, the cam forces the valves downward into the cylinder. The pressure inside the combustion chamber aids in sealing the valve shut.

9. The Exhaust and Intake Valves

The charge (or air) that enters the engine for burning and the exhaust gases that escape the cylinder are controlled and regulated by the inlet and exhaust valves, respectively. They could be held in the cylinder heads as well as the cylinder walls. They typically have heads that resemble mushrooms.

In petrol engines, the entrance valve is where the air and fuel mixture enters. In contrast, the intake valves of diesel engines can only admit air. In any case, the exhaust valve’s objective is to release exhaust gases.

Exhaust valves are linked to the exhaust manifold, whilst intake valves are attached to the intake manifold. We’ve talked about intake and exhaust manifolds before.

10. The Oil Pan

The lower portion of the crankcase is referred to as the oil pan or sump. It is fastened to the crankcase with set screws, and a gasket seals the contact to stop leakage.

The oil pan serves as a storage, cooling, and ventilation system for engine lubricating oil. When changing the oil, a drain plug is inserted at the oil sump’s base to enable the removal of the used oil. The sump is frequently constructed from pressed steel sheets or cast aluminum alloy.

This auto engine component helps to maintain the moving parts of the engine lubricated, which reduces friction and makes for simple operation. Since the oil pan maintains the oil inside the lubricating system, it cannot seep out.

Since the oil pan is a metal component attached to another metal component of the engine, there is a gasket between them. To prevent engine oil leaks, the old gasket might need to be quickly replaced.

11. The Combustion Chamber

The combustion chamber refers to the area of the cylinder where the fuel/air mixture ignites. The fuel/air mixture is forced out of the combustion chamber as mechanical energy after being squeezed by the piston and ignited when it makes contact with the spark plug.

The Cylinder is the housing for the Injector Nozzle, Piston, Spark Plug, Combustion Chamber, and other important internal combustion engine parts.

12. The Manifolds

Separate sets of pipes, referred to as manifolds, attached to the cylinder head carry the air-fuel mixture and exhaust gases. It is normally built of cast iron to be able to resist the high temperature of exhaust gases. It consists of the carburetor flange, air intake flange, throttle body flange, and intake manifold flange for the tailpipe.

The Intake Manifold: The intake manifold is a component of an automobile engine that distributes the airflow between the cylinders. An intake manifold frequently serves as a home for the throttle valve (also known as the throttle body) and other components.

Some V6 and V8 engines have an intake manifold that is made up of multiple unique parts or segments. Before entering the engine, the intake air goes through the air filter, intake boot (snorkel), throttle body, intake manifold plenum, runners, and cylinders. By changing the airflow, the throttle valve (or body) controls the engine rpm.

The engine’s intake manifold by Alison Cassidy / CC BY-SA 3.0. An automotive engine’s intake manifold is a part that divides the airflow between the cylinders. The throttle valve, also known as the throttle body, and other parts are usually housed in an intake manifold.

The exhaust manifold: The exhaust manifold, which gathers exhaust gas from many cylinders of the engine and feeds it to the exhaust pipe, is frequently a simple cast iron or stainless-steel arrangement.

The exhaust valves are involved. Its layout is the same as the inlet manifolds. In both diesel and gasoline engines, the exhaust manifold transports exhaust gas for the same reason.

13. The Spark Plugs

A spark plug is an electrical part that ignites compressed aerosol fuel using an electric spark in internal combustion engines. It’s crucial to use the electrical component when doing mechanical operations.

A spark plug is a part that carries electric current from an ignition system to the combustion chamber of a spark-ignition engine to ignite the compressed fuel/air combination by an electric spark and maintain engine combustion pressure.

The ceramic insulator in the spark plug is used to keep the metal threaded shell and core electrode apart in the vehicle engine component. The output terminal of a magneto or ignition coil is connected to the central electrode, which may also include a resistor, by a highly insulated wire.

14. The Connecting Rod

The fundamental function of the connecting rod is to convert the piston’s reciprocating action into the rotational motion of the crankshaft. It must be light and sturdy enough to withstand pressure and twisting forces.

The connecting rod typically has an I-beam cross-section and is drop-forged from alloy steel or duralumin. Recently, it has also been cast from spheroidal or malleable graphite C.I.

The piston is fastened to the tiny end of the connecting rod with either a solid eye or a piston pin. The big end of the connecting rod is always split in half to connect the crank pin of the crankshaft.

Additionally, the connecting rod and crank work together to convert the piston’s reciprocating action into the spinning of the crankshaft. The connecting rod is required to transfer the compressive and tensile forces applied to the piston.

In an internal combustion engine, which is where it is most usually utilized, it can pivot on the piston end and rotate on the shaft end.

The predecessor to the connecting rod is a mechanical device used in water mills to convert the water wheel’s spinning motion into a reciprocating motion.

15. The Water Pump

In a car, the water pump is a belt-driven mechanism that is powered by the crankshaft. The water pump is designed like a centrifuge and draws the cooled fluid from the radiator through the pump’s central input.

After being cycled outward into the engine, the fluid is subsequently returned to the car’s cooling system.

16. The Drive Pulley for a Timing Belt

Timing belt pulleys are a special kind of pulley system with teeth or pockets along the outside of the pulley body’s diameter. The pulley’s teeth and outside pockets do not transfer power. Instead, to help with timing and avoid misalignment, they engage the pulley belt.

A timing belt is being installed by Petar Milošević / CC BY-SA 3.0. A unique type of pulley system having teeth or pockets along the outside of the pulley body’s diameter is timing belt pulleys. Power is not transferred by the pulley’s teeth or outside pockets. Instead, they engage the pulley belt to aid in timing and prevent misalignment.

17. An Oil Pan Drain Bolt

The oil drain plug is often located on the engine’s oil pan near the bottom. It is used to drain the oil from your pan during an oil change. Sometimes simply changing the gasket is enough to stop an oil plug leak.

If the bolt or oil pan has been cross-threaded, a new oil drain stopper may be required. A big oil drain stopper may occasionally cut new threads, helping you avoid replacing the entire oil pan.

18. The Piston Rings

The piston rings are fitted into the grooves of the piston to provide a tight seal between the piston and the cylinder wall. The outside diameter of a piston is connected to a metallic split ring known as a piston ring in a steam engine or internal combustion engine.

As opposed to more current designs, which typically have 3 compression rings and 1 oil control ring per piston, older designs typically have 2-4 compression rings and 1-2 oil control rings per piston.

The piston ring seals the crankcase from high-pressure gases coming from the combustion chamber. The piston ring allows heat to easily transfer from the piston crown to the cylinder walls.

The piston ring also makes sure that there is enough lubricant on the cylinder walls for the duration of the piston’s travel, which lessens cylinder wear. The principal functions of piston rings in engines are as follows:

- Reducing gas leakage into the crankcase by sealing the combustion chamber.

- Increasing heat transfer from the cylinder wall to the piston.

- Ensuring that the piston and cylinder wall are separated by the appropriate amount of oil.

- Bringing back scraped oil to the sump helps to reduce the amount of engine oil used.

- Piston rings are commonly made of cast iron or steel.

19. The Flywheels

Utilizing the idea of conservation of angular momentum, a mechanical device known as a flywheel store rotational energy, a kind of kinetic energy proportional to its moment of inertia and the square of its rotational speed.

Torque is produced by the engine, however, it varies and is not continuous. If a vehicle continues to move when this unpredictable power is there. It will also reduce the lifespan of its numerous components in addition to making the rider highly uncomfortable.

To solve the problem of fluctuating load, a flywheel is used. A flywheel is often mounted on the camshaft. When the torque is high during a cycle of operation, it builds it up and releases it when the torque is low. It functions as a torque buffer.

20. The Cylinder Liner

These cylindrical forms are utilized in the cylinders to avoid the problem of cylinder wear. It is one of the most significant internal structural elements of an engine. These can be replaced if they start to wear out.

They are made of an iron alloy containing chromium, nickel, silicon, and manganese. Usually, these are centrifugally cast. These liners are resistant to wear and corrosion. The engine has a much longer lifespan thanks to these oil-hardening liners.

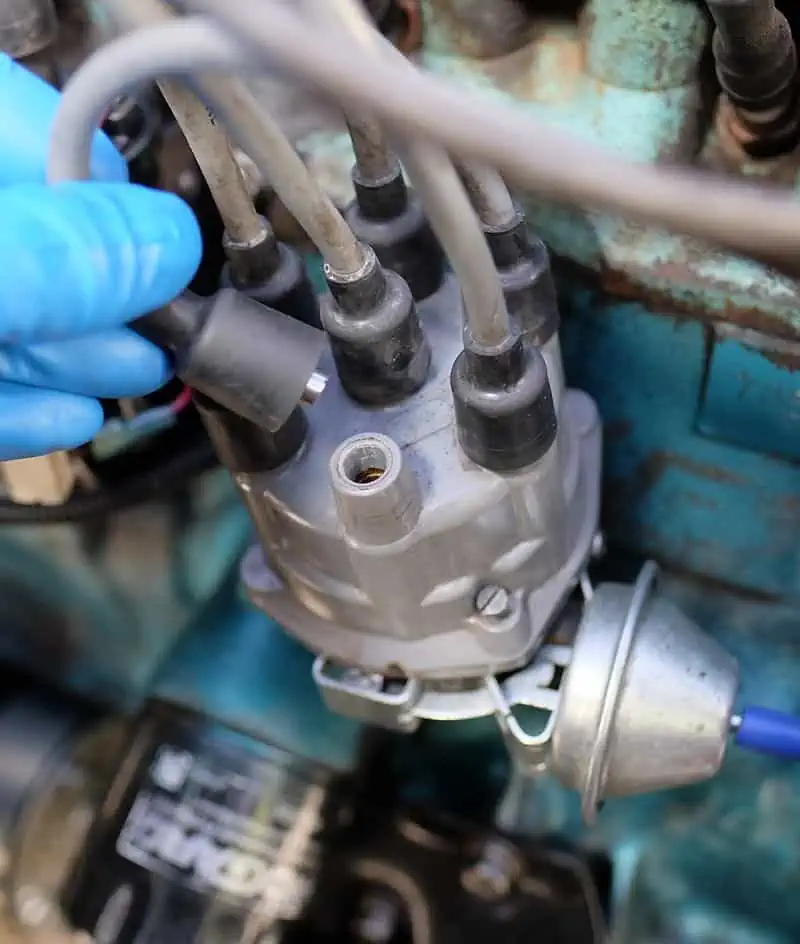

An engine distributor by Dennis Bratland / CC BY-SA 4.0. In internal combustion engines with mechanically timed ignition and spark ignition, a distributor is an enclosed rotating shaft. The distributor’s primary duty is to deliver secondary, or high voltage, current from the ignition coil to the spark plugs in the appropriate firing sequence and for the appropriate length of time.

The cylinder liner, which serves as the cylinder’s inside wall and keeps lubricant inside, creates a sliding surface for the piston rings.

The cylinder liner ages with time due to friction between the piston rings and the skirt. This wear is minimized by a glaze that forms naturally while the engine is operated and a thin oil coating that covers the cylinder walls.

21. The Distributor

A distributor is an enclosed rotating shaft used in internal combustion engines with spark ignition and mechanically timed ignition. Delivering secondary, or high voltage, current from the ignition coil to the spark plugs in the right firing order and for the right amount of time is the distributor’s main responsibility.

Except for magneto systems and many modern computer-controlled engines that make use of crank angle/position sensors, the distributor also has a mechanical or inductive breaker switch to open and close the ignition coil’s primary circuit.

22. The Camshaft Pulley

The timing system of an engine uses a cam pulley to control the rate of rotation of the camshaft, which in turn controls the poppet valves that manage air intake and exhaust in the cylinders. The crankshaft and camshaft rotation are synchronized via the timing chain and cam pulley.

23. The Oil Filter

The oil filter in your car also gets rid of waste. Your car’s engine filters the motor oil to get rid of potentially harmful dirt, metal shavings, and debris to keep it running smoothly.

Dangerous pollutants could enter your motor oil without a filter, destroying the engine. If you filter away the garbage, your engine oil will stay cleaner and last longer.

24. The Gudgeon Pin

An integral part of an internal combustion engine is a gudgeon pin, often called a wrist pin.

It establishes a link between the piston and the connecting rod. Additionally, connecting rods, wheels, or cranks can be employed with gudgeon pins.

25. The Cam

They are a crucial component of camshafts. A camshaft is called a camshaft because of cams. To regulate the timing of the inlet and exhaust valves, the cams are positioned on the camshaft.

26. The Distributor O Ring

The distributor o-ring, which is frequently used by distributors to seal the distributor’s shaft with the engine, is an O-ring that is sized particularly to fit on the distributor’s shaft.

To stop oil leaks at the base of the distributor, the distributor o-ring merely seals the distribution housing with the engine. O-ring failure can result in oil leaking from the distributor’s base, which can create other issues.

27. The Rubber Grommet

Rubber grommets are utilized to seal holes, cover exposed surfaces, and lessen vibration. Sharp edges can be reduced and the engine valve can be protected when passing through a hole by inserting a rubber grommet. The valve will be protected from harm by the rubber grommet.

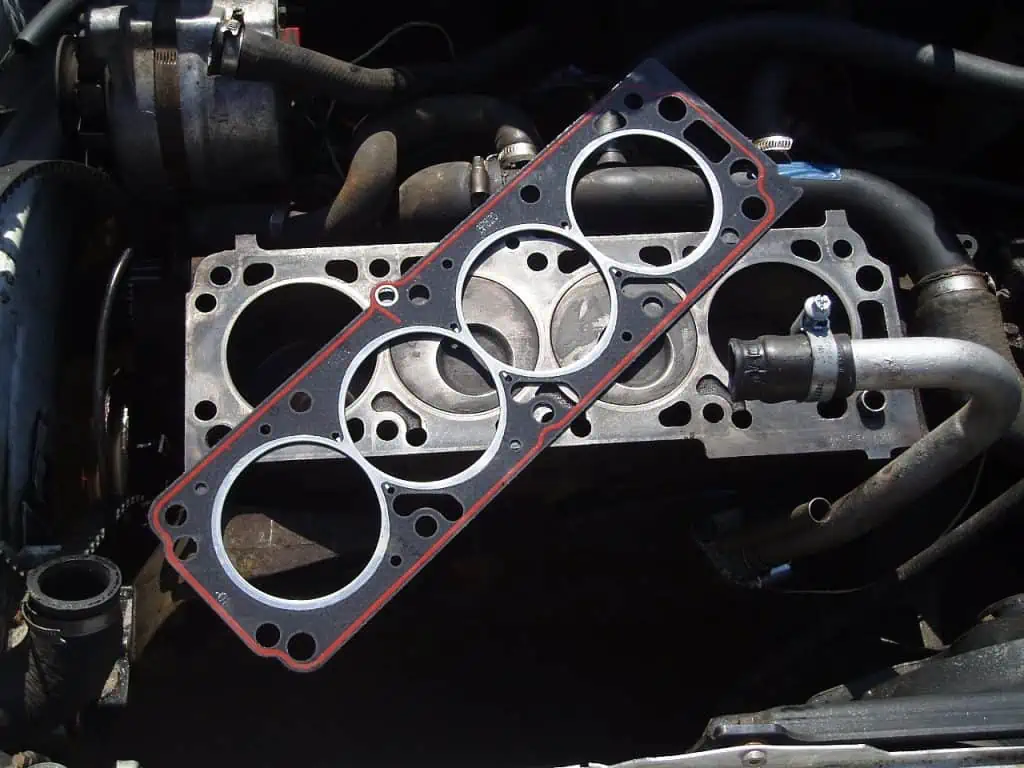

The engine’s head gasket by Collard / CC BY-SA 3.0. A head gasket serves as the seal between the engine block and cylinder head. Its major job is to stop coolant or engine oil leaks while sealing the combustion gases inside the cylinders. Leaks in the head gasket can cause the engine to overheat or run poorly.

28. The Gaskets

In static applications, a gasket is a ring or sheet made of flexible material that is used to seal joints, flanges, and other mating surfaces to stop leakage.

These several gasket varieties are frequently used in engines:

The head gasket: The seal between the engine block and cylinder head is provided by a head gasket. Its main function is to seal the combustion gases inside the cylinders and prevent coolant or engine oil leaks. Head gasket leaks may result in overheating or poor engine performance.

The intake manifold gasket: Air, coolant, and oil leaks are stopped by the intake manifold gasket, which closes the tiny opening between the manifold and the engine. The intake manifold gasket experiences significant wear and tear over time. It might eventually develop cracks or warps that make leaks possible.

The exhaust manifold gasket: To achieve the best seal, the exhaust manifold gasket is typically a multi-layered gasket made of metal and other materials. As the first gasket in the exhaust system, the exhaust manifold gasket is a crucial seal that needs to be checked if any issues develop.

The water pump gasket: The gasket for the water pump is a ring-shaped component composed of a tough material that can resist a range of temperatures. One of the major parts that move coolant throughout the engine is the water pump, therefore if it lacks a tight-fitting water pump gasket to keep it sealed, a leak could develop between it and the engine block.

The oil pan gasket: The oil pan gasket itself keeps oil from leaking as it travels from the pan to the engine and back by sealing the oil pan to the engine block’s bottom. However, no vehicle is invincible to oil leaks because oil is always flowing. The oil pan or a worn oil pan gasket is frequently the source of oil leaks.

The Conclusion

In an automotive engine, the energy created during the combustion of gasoline and air is used to propel the vehicle. When the car is moving, the engine draws air from the intake system. This air is mixed with the gasoline that the fuel injectors give.

The mixture is ignited inside the engine after compression and ignition, resulting in a series of little explosions that keep the engine turning continuously. The drivetrain moves the vehicle forward by transferring the engine’s rotational force to the driving wheels.

Several components are essential for the engine to function flawlessly with this common technology to function. That concludes my essay on the components of an automobile engine. I hope the engine has taught you a lot; if so, please spread the word to others. Regards and thanks for reading.

A fully closed cylinder block by 160SX / CC BY-SA 3.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”