Are you beginning to notice that the gearbox slips gears more frequently and that the car’s transmission just doesn’t feel right? Do you think that these are some of the telltale signs of a damaged torque converter?

If so, you have come to the correct spot because you are about to discover everything there is to know about these symptoms.

Nothing is worse than experiencing a transmission issue. Both replacing and repairing transmissions are costly. You should therefore take prompt action and save what you can before the transmission fails whenever this starts to happen to you.

However, there are situations when the torque converter as well as the transmission is to blame for issues. And the awful thing about these two is that the symptoms of a damaged torque converter and a bad transmission are quite similar.

The untrained eye finds it challenging to determine which one of these components has failed. However, you shouldn’t worry since we’ll take care of you.

We will first discover what a torque converter is and its parts. The operation of a torque converter and its warning signs will next be covered in detail.

Following that, we will discuss how to identify and fix this issue with your automobile and how much it will cost you to do so. So, keep reading if you want to discover more.

A Torque Converter: What Is It?

Now let’s cover the fundamentals and learn something about this device in general before we get into more complicated subjects and begin to comprehend how a torque converter functions and the signs of a damaged torque converter.

Knowing the fundamentals will help you troubleshoot issues more effectively and you’ll have a better understanding of how this component functions as a whole and what to anticipate from it.

However, a torque converter is a part that is employed by conventional automatic gearboxes. Since they use this part, these gearboxes are often referred to as torque converter automatics.

Torque converters are a common feature of gearboxes. However, there is still a small amount of CVT and DCT transmissions. Additionally, most CVTs have a torque converter. So, what exactly is a torque converter?

A torque converter, then, is a component that is located in between the transmission and the engine. A fluid coupling mechanism prevents the vehicle from stalling out when it comes to a halt. Additionally, to boost pulling power, the torque converter multiplies the engine torque.

The torque converter is attached to the engine’s flexplate on one side and the transmission on the other.

The torque converter is connected to the engine through the transmission shaft, which also travels through it. Before learning the signs of a faulty torque converter, we’ll go into more detail about how the torque converter works, but first, let’s learn more about the torque converter components.

What are the Components of Torque Converters?

Now let’s study more about the components of the torque converter before we understand the signs of a damaged torque converter. Let’s learn more about the parts that make up this converter.

Knowing the parts will make the diagnostic procedure much simpler, and you will be able to determine if the problem is with the torque converter or the automatic transmission. Therefore, what parts make up this torque converter? Let me clarify.

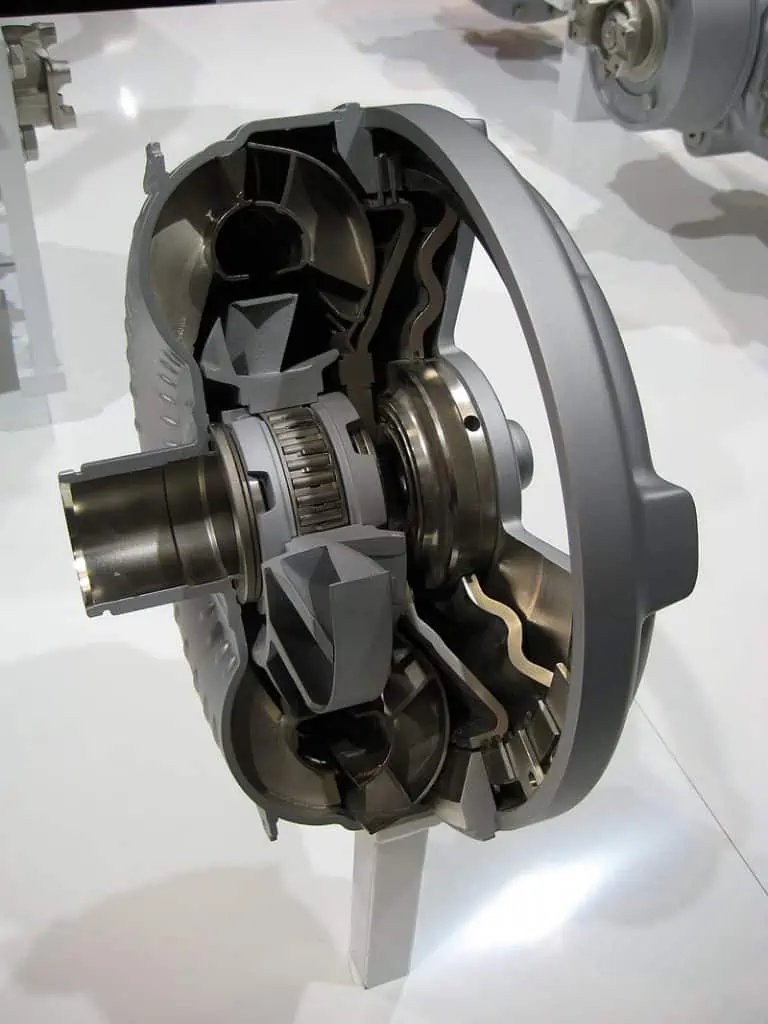

ZF torque converter cut-away by Aconcagua / CC BY-SA 3.0

The torque converter is an enclosed machine with parts within. You won’t ever see an electrical component inside of this torque converter; it functions with the aid of hydraulic fluid.

The impeller or torque converter pump is the first part that emerges from the side of the engine. As the engine turns, the impeller also turns. This part, which contains blades, performs all the labor-intensive tasks and serves as a centrifugal pump.

The fluid is rotated by this impeller toward the turbine in an outward direction. Another element attached to the transmission’s input shaft is the turbine.

A stator/reactor is located between the turbine and the impeller. The stator, a part that can only travel in one direction, becomes stuck while the engine is running above idle.

This causes the turbine to experience centrifugal force, which amplifies the torque and provides your automobile its pulling power. Overall, this is a difficult technique to grasp on your first attempt.

You can better comprehend the signs of a failing torque converter by comprehending how the torque converter functions.

How Does a Torque Converter Work?

Understanding the torque converter’s function is crucial to ensuring that the transmission operates properly.

You don’t have to be an expert in impeller, stator, turbine, and clutch science. You simply need to be aware of this component’s two main objectives.

This part’s primary function is to stop your automobile from stalling at idling. Simply put, the torque converter in a manual gearbox is equivalent to your clutch.

Your automobile won’t stall as a result of the torque converter transferring this motion to the transmission when the transmission is disengaged.

The torque multiplier nature of this torque converter is the second item to be aware of. Since engine power propels you ahead, torque is one of the most crucial factors, as you undoubtedly well know.

Additionally, the transmission is a straightforward torque converter that transforms the engine’s crankshaft’s rotational speed into torque.

Additionally, the torque converter multiplies this power to assist you to generate more torque while also enhancing the overall performance of the vehicle.

Therefore, based on its intended use, we can say that this is a highly significant mechanism that is in charge of regulating the torque distribution to the wheels.

You will experience symptoms of a malfunctioning torque converter when this converter is not functioning, and we will go into more detail regarding these symptoms in the section that follows.

Where Is the Torque Converter Located?

Between the engine and the automatic transmission is where the torque converter is situated.

You must take the engine and transmission out of the automobile to properly identify the issue and do a visual check.

A cover plate on some vintage American automobiles may be removed to view the torque converter. However, even with them, the torque converter is a sealed mechanism, so you won’t see much.

It is always advised to take the torque converter off of the transmission for an accurate diagnosis.

What are the Common Bad Torque Converter Symptoms?

Let’s now go on to the most crucial part of this essay, which discusses the signs of a failing torque converter.

As you are surely aware, there will always be indications present when a component fails or is about to fail. You should thus be familiar with each one of them.

Fortunately for you, we are going to share them all with you and, on top of that, we are going to offer our assessment of how likely each one is to occur whenever there is a torque converter issue. So read on to the end if you want to understand more about this.

The Check Engine Lights Illuminate

The check engine light is the first sign on our list of signs of a malfunctioning torque converter.

The transmission still has several solenoids that control the torque converter’s operation even though it is not directly connected to the PCM. If one of these solenoids fails, the gearbox’s check engine light will be on.

However, until the torque converter is taken out of the automobile and thoroughly inspected, you will never be able to tell if it is damaged.

However, the P0740 to P0744 code range is the one most frequently associated with torque converter issues. These codes are particularly important since they suggest a problem with the torque converter clutch solenoid.

Therefore, anytime one of these codes appears, you should further examine it to determine whether the solenoid is malfunctioning. If it is not, the converter is the problem, and this component likely has to be replaced. Let’s move on to the additional signs of a failing torque converter.

Undesirable Torque Converter Noise

The torque converter noise is the third sign on our list of signs of a malfunctioning torque converter. Different sounds will start to emanate from the transmission once this component begins to malfunction.

You might at first assume that a faulty transmission is to blame for this. However, since this converter might sometimes result in issues like these, this isn’t always the case. What sounds emanate from this component most frequently?

The whining noise is the most typical sound connected to a damaged torque converter. These whining noises appear whenever the torque converter begins to malfunction.

Similar sounds might be heard when a power steering pump begins to fail. They are so similar since they both employ hydraulic fluid and have comparable functions.

The whining noise is frequently the result of a deteriorating clutch mechanism, and when the clutch pack begins to ratchet due to excessive wear, the torque converter may also fail.

Burn Out due to bad torque converter by Chad Horwedel / CC BY-NC-ND 2.0

This is why you need to watch out for these signs that your car’s torque converter is malfunctioning. Let’s move on to the following symptom now.

Variable Vehicle Speeds

Inconsistent vehicle speed is another sign of a faulty torque converter on our list. A faulty torque converter clutch pack is frequently the culprit in this.

Simply put, the torque converter will begin to malfunction. The speed of the automobile will be affected when it engages and when it disengages.

The torque converter’s internal hydraulic pressure won’t be able to handle the load and will fluctuate constantly. And when this occurs, driving the automobile will be quite challenging since the speed will not be constant.

You can stall out if you accelerate too rapidly. And it’s dangerous to drive this automobile. Simply put, you don’t want your gearbox to fail and leave you stranded in the middle of the road.

You must address this issue and try to resolve it as soon as possible whenever there are sudden variations in speed that don’t correspond to your pedal input.

In all honesty, this is one of the clearest indications that you have a problem of this nature. Watch out for these signs of a malfunctioning torque converter before moving on to the next sign.

Transmission Shuddering

The gearbox shudder is the third sign on our list of signs of a malfunctioning torque converter. A gearbox shudder occurs when the clutches inside the torque converter aren’t functioning properly. What, though, is a shudder?

When the transmission begins to vibrate, it is when you encounter a transmission shudder. When you accelerate, this transmission shudder will become more noticeable. especially in the range of 30 to 45 mph.

The console will tremble and shake, and you’ll notice that the transmission is vibrating. This trembling will spoil your day.

You could initially speculate that this might be an issue with the transmission. However, it’s not always the case. Even though unclean or low transmission fluid can also cause the gearbox to tremble.

However, you still need to investigate deeper and identify the issue. We’ll also describe how to accomplish it later on in the text.

Excess Heat from the Transmission

The circumstance in which your gearbox begins to overheat is the next sign on our list of signs of a damaged torque converter.

On these gearboxes with worn torque converters, this is frequently the case. The gearbox fluid is filled with a ton of clutch debris. Additionally, this fluid damages you by causing the gearbox to overheat.

When this happens, the transmission may cease shifting or the car may alert you to stop driving so it can cool down.

Burn Out due to bad torque converter by Chad Horwedel / CC BY-NC-ND 2.0

In these circumstances, checking the transmission fluid’s condition is crucial. Most frequently, low fluid levels or contaminated fluid can make the torque converter malfunction and overheat the transmission.

Because of this, handling the fluid should be your priority to prevent the issue from getting worse. Let’s now discuss the following signs of a failing torque converter.

Slipping Transmission Gears

The gearbox sliding gears are the next sign on our list of indicators of a malfunctioning torque converter.

This is a very typical problem when the torque converter breaks. Simply said, the torque converter is internally broken and unable to manage the gearbox fluid properly.

Fluid can be injected into the automatic gearbox either in excess or insufficiently. And when this occurs, the transmission will slide gears. What happens when the gearbox slips gears, though?

The gearbox failing to maintain a certain gear and abruptly dropping one or two gears might be used to explain this occurrence. It slides gears as a result.

Therefore, the first thing you should do anytime you observe anything similar is to check the fluid level. If the fluid is good, it suggests that the issue is either with the transmission’s internals or the torque converter.

Let’s now discuss the final sign on our list of torque converter warning signs.

Stalling Concerns

The stalling problem is the final sign of a faulty torque converter on our list. When the torque converter malfunctions, the engine will either stall at the starter or its RPMs will rise.

The stalling issue is present in our scenario. So, when your automobile stalls at idle, it’s not always an ignition issue. It can just be a defective torque converter failing to maintain engine stability when the engine is idle.

But how can you know whether or not a torque converter is reliable? In the subsequent chapter, we will go into more depth about this and describe how it is done for you to have a clearer understanding of what to anticipate when you run tests on the torque converter.

What are the Causes of the Bad Torque Converter Symptoms?

You need to be cautious of what can cause your torque converter to fail before it starts to fail. Consequently, the following are a few of the reasons why torque converter issues arise.

Torque Converter Seal Damage

Transmission fluid inside the bell housing may leak if the torque converter seal is compromised. The torque converter won’t be able to deliver a smooth transfer of power from the engine to the transmission in the situation. As a result, among other issues, there can be overheating, slippage, and greater stall speeds.

Defective Torque Converter Clutch Solenoid

The torque converter clutch solenoid is an electrical component that aids in fluid pressure measurement and control of the amount of fluid supplied to the lockup clutch.

A malfunctioning solenoid prevents an appropriate assessment of the amount of transmission fluid required, which may result in aberrant fluid pressures. As a result, strange behaviors like low gas mileage and engine stalling, among others, could occur.

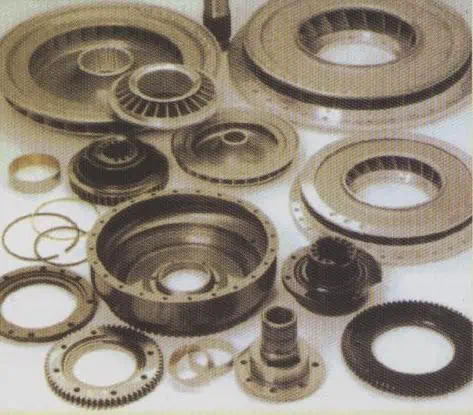

Torque converter: transmission: Replacement Aftermarket parts by Devendra Dave / CC BY-SA 2.0

Torque Converter Clutch That Is Worn Out

Clutches on the torque converter aid in locking the engine and gearbox into direct drive. The automobile could, however, continue to be in gear long after the driver has stopped if the torque converter is faulty. This converter can potentially lock into direct drive, particularly if the friction material on the clutch plate is worn out.

Defective Needle Bearings

The stator, turbine, impeller, and converter housing are separated by needle bearings. Alternately, the noisy operation might be caused by defective bearings. Metal-to-metal contact between these torque converter components could also result in the buildup of metal chips in the gearbox fluid.

What are the Four Typical Torque Converter Issues?

There are a few typical issues that might arise with torque converters. Older cars typically include a torque converter, which is not a highly sophisticated component and has few potential failure points.

It is occasionally possible to locate inexpensive whole replacements for torque converters, in which case it is frequently not necessary to disassemble the converter and replace individual components because doing so is both more expensive and time-consuming.

The Defective Torque Converter’s Bearings

The torque converter bearings are often worn, which is an issue. Although it doesn’t cause slippage or other transmission issues, this might result in the transmission making bearing noises.

If the transmission makes bearing noises, examine the transmission fluid to see if you can see any metallic particles there. If you discover metal fragments, the torque converter bearing is probably to blame.

The Faulty Torque Converter Seals

The pressure inside the converter will be lost if the torque converter’s seal fails, which will result in transmission fluid leaking out.

Slippage, overheating, and other unusual symptoms are all caused by low pressure inside the torque converter. When it comes to a bad torque converter, this is one of the most frequent issues.

The Bad Torque Converter Clutch Plate

A torque converter has several clutches. The converter clutch is probably malfunctioning if the torque converter is stuck in the driving or idle gear and won’t let the gearbox out.

Other signs of a bad torque converter clutch include sliding and jerky acceleration.

The Malfunctioning Torque Converter Clutch Solenoid

One component that frequently breaks down in an automatic gearbox is the torque converter clutch solenoid. The hydraulic transmission’s fluid pressure as it approaches the lock-up clutch is managed by the solenoid valve.

Numerous symptoms, including sliding, overheating, and jerky acceleration, may result from this.

Billet torque converter by lw5315us / CC BY-SA 2.0

How Can You Diagnose the Bad Torque Converter Symptoms?

Let’s now move on to something else. Specifically, the torque converter’s diagnostic procedure. Let’s find out more about how to correctly diagnose this component and what you can do to fix it.

The first thing you should watch out for are the symptoms, as we already indicated. Transmission whine, trembling, engine stalling at idle, or check engine light.

These are all possible signs of a failed torque converter. You must diagnose the converter if you have one of them, especially if it is directly linked to this component.

For instance, when the OBD2 scanner displays codes in the P0740 to P0744 range. All of these codes have a tight connection to either this part of the TCC solenoid. Both of these elements need to be examined in these circumstances. The torque converter is likely damaged if the solenoid is in good condition.

An air compressor will be your sole requirement. However, removing this component, which might be challenging, is the problematic part. You must replace this component if you believe it to be defective.

Replacement of a Bad Torque Converter

Now that all indications of a damaged torque converter have been eliminated, let’s move on to other subjects and discover more about the replacement of this component.

It’s important to note that replacing this component is not a task for novices. You will want a lift for this task, as well as an additional pair of hands to assist in lowering the gearbox and replacing it. For this reason, we advise having it replaced at a store.

How Much Does the Bad Torque Converter Replacement Cost?

Depending on the automobile type and labor expenses, the typical cost to replace a torque converter ranges from $350 to $2550. Costs for brand-new replacement torque converters range from $150 to $450. The torque converter replacement will cost between $250 and $2050 in labor.

The torque converter must frequently be replaced or checked for any issues by removing the transmission.

Depending on your expertise and ability level, replacing the torque converter will take anywhere from 3 to 12 hours.

Can You Keep Driving with the Bad Torque Converter Symptoms on Your Vehicle?

No. A gearbox can suffer harm from bad torque converter symptoms. Damage, overheating, friction, and transmission fluid deterioration can all be caused by defective torque converters. The transmission may suffer considerably greater harm if these issues persist.

Additionally, A vehicle will abruptly halt and experience substantial speed fluctuations as a result of a malfunctioning torque converter. It will cost you money to repair your car’s transmission system and effectively harm other engine parts.

As a vital part of a car, the torque converter must function correctly to provide a comfortable ride. Your automobile will experience severe issues when the torque converter is malfunctioning. In some cases, a damaged converter can prevent your automobile from moving at all.

Mercedes-Benz 7G-Tronic transmission by https://att24.de/ / CC BY 4.0

Even if your torque converter solenoid is subpar, you can still operate a vehicle. You are okay to go as long as the shift solenoid does not change gears more than once.

As a result, you won’t have any trouble driving to a mechanic’s shop to get your issue resolved.

A torque converter converts the power from your engine into rotational energy.

Transmission fluid will have issues if the torque converter malfunctions since it won’t be able to feed through the pump in the torque converter.

As a result, the entire system will have several issues. As a result, it’s advised to take extra precautions, among other things.

Conclusion

Once you are aware of the indications to look out for, bad torque converter symptoms may be avoided. Fixing the symptoms is crucial when you become aware of them.

Now that you are aware of the reasons for torque converter failure, the signs of a damaged torque converter, and a simple remedy for a failed or subpar torque converter.

Call your technician to undertake the repair if you lack the confidence to complete it yourself.

In comparison to the harm, the torque converter may do to the gearbox if it were neglected for a long period, the expense of repair or replacement is little.

Therefore, it’s critical to identify and address bad torque converter symptoms early on.

Nyangano Maurice specializes in vehicle troubleshooting and has more than 10 years of experience in the automobile industry. Over many years of experience as a car mechanic, he has acquired a broad range of skills, including engine repair, brake systems, electrical systems, and more. He frequently hosts community workshops and training programs to help motor vehicle owners understand their vehicles better.