The ends of the drive shaft on all FWD (front-wheel-drive) cars are fitted with CV joints. There are two different sorts of these joints: a tripod-type joint is utilized for the inner CV joint and a ball joint is for the outside CV joint.

These joints are important mechanical parts of the suspension system of your car, which enables you to drive it comfortably and easily. When going straight or making curves with your car, CV joint noise might occur if any component of the inboard or outboard CV joint is damaged.

Driving becomes awkward and challenging due to this flaw. Continue reading to learn the likely reasons for your faulty CV joint so you can perform a fault inspection and figure out how to solve this issue. Additionally, you will learn how to fix problems if you need to replace your CV axle or change your boots.

A CV Joint: What Is It and How Does It Work?

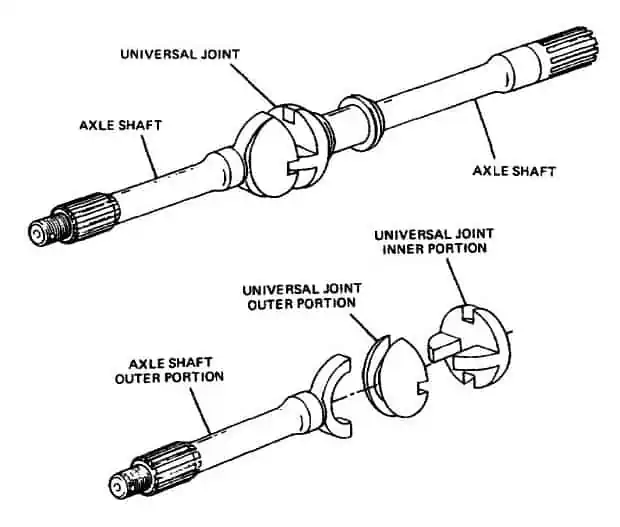

The transmission is typically connected to the wheels by CV joints, also known as constant velocity joints. These joints are exclusive to four-wheel drive vehicles, while some four-wheel or rear-wheel drive vehicles may also have them.

Modern vehicles now have CV joints in place of EU joints. These joints’ primary function is to make the wheels always move at the same speed.

These CV joints are special in that they combine two distinct fixed shafts. Their function is to enable the wheels to travel and maintain consistent speeds while being unaffected by the various shaft angles.

According to experts, the outer CV joints on the wheels will degrade before the inner ones do. Therefore, you should examine the outside joints before evaluating the inner ones if you think there might be a problem with the CV joints.

There will come a moment when you need to replace your CV joints because they are not made to last forever. CV joints typically degenerate as a result of issues with the fall protective boot because it cracks.

If this boot cracks, a lot of debris and moisture could enter, causing the TV joints to prematurely fail. Additionally, excessive friction can result in serious corrosion and overheating in CV joints that do not receive enough lubrication.

Experts predict that the exterior CV joints on the wheels will experience degradation before the inner ones. Therefore, if you think there might be a problem with the CV joints, you should check the outside joints before checking the inner ones.

To avoid unfavorable outcomes, you must get the car inspected and the CV joint boots replaced right away if you discover any signs of corrosion or cracks.

What Results In CV Joint Noise When Driving Straight?

It suggests that your CV joint is defective but may not be completely broken as there are elements that might impact your joints’ functionality if you hear noises from it when driving straight or making fast curves.

Your joint may squeak for a variety of reasons, some of which are as follows:

1. Defective CV Boots

Your CV joints frequently experience problems with cracked, ripped, or broken boots. Grease will start to flow out of cracked boots, which can lead to an accumulation of dirt on the joint and speed up the wear and tear on your CV joint, and potentially cause it to stop working altogether due to corrosion and lack of lubrication. Another factor that gradually deteriorates your joint is the CV joint, which is likewise contaminated by debris.

Grease leaking from your CV boot due to a tear or split indicates that your CV joint or boot is broken. In the event of serious damage, grease will be visible inside the rim of your wheel as well as inside the drive wheel area. As your CV axle rotates, including your chassis, the leakage is most likely to penetrate various areas of your car. All of these produce CV joint noise while moving faster or making abrupt turns.

When turning while moving at a high speed, the noise gets louder. Your CV joint may become entirely ruined if you drive when it is injured.

2. Defective Boot Clamps

Boot clamps secure your CV boots in place. These clamps assist in making sure the boots are tightly sealed, shielding your CV joint from any exposure. If your boot clamps are broken, your CV boot will become loose and enable debris to build up inside your CV joint. This impact will result in an inner CV joint clunk, which will eventually cause your CV joint to start making noises while you’re driving.

So, if you hear any clunking or squeaking coming from the joint area, examine the clamps, the boot area, and the entire boot.

3. Reduction In Lubrication

Because of increased friction caused by poorly lubricated CV joints, your CV axle won’t be able to easily rotate. Your CV joints may create noise each time the axle turns if they are not sufficiently greased.

This implies that anytime you drive your automobile, you will hear noise coming from the inner CV joints. When moving quickly, the noise gets louder. If you are merely traveling at a modest pace, you might not hear the noise.

A Constant Velocity Joint by Nutzdatenbegleiter / CC BY-SA 3.0. You will be considerably better off if any issues with the CV joints are discovered early on before they worsen and extend to other regions. One method to do this is to listen for CV joint sounds when traveling straight.

4. The CV Joint Aging

Axles that have been in service for a very long time will eventually develop steering noise or joint noise. This will happen because the joints need to be replaced. After all, they are worn out.

Every mechanical part will ultimately need to be replaced, thus this situation is very natural. Although they are strong, they cannot last forever.

What are the Symptoms of a Bad CV Joint?

If you catch any problems with the CV joints early on before they get worse and spread to other parts, you will be much better off. Observing CV joint noise when driving straight is one way to do this.

In addition to listening out for CV joint noise when driving, it’s also a good idea to listen out for it when braking. Here are a few typical signs of a malfunctioning CV joint.

1. Car Vibrates While Driving

Not simply problems with CV joint noise when driving, but a whole variety of other concerns can result in vibrations. However, there is a potential that you may have damaged CV joints if you notice that the vibrations get worse whenever you speed or if there is some “bounciness” to the vibrations.

When braking, you might hear CV joint sounds. Whether or not the vibrations are brought on by problems with the CV joint, you must have your car inspected as soon as you discover them.

2. Grease Leakage on the Internals of the Tires

When the axle rotates, the CV joint’s boots keep the grease in place. During this spinning, the grease is kept from leaking out thanks to the CV joint boots.

If the CV boots are harmed, the grease will leak as a result. A lack of goodwill causes the metal components to deteriorate and cause serious harm to the CV joint. This causes CV joint noise during braking or when traveling straight.

Bring your car in for repairs immediately if you notice oil on the inside of the wheels.

3. Knocking Noises

You might hear constant clunking and knocking. For instance, the noise made by the CV joints when they accelerate may be the cause of this. When braking, it could potentially produce CV joint noise. It’s also possible that the car just makes noise when turning right, not left.

While it’s important to keep in mind that there may not always be a problem with the CV joint, good procedure mandates that you undertake an inspection just to be safe. At least you’ll be able to identify and address the precise sources of CV joint noise while driving.

Putting the car in reverse and listening to the knocking sound will help you confirm. If so, there’s a good probability your CV joints are injured. If so, bring the vehicle in for service.

What Is Likely to Take Place When the CV Joint Fails?

Due to the direct connection between the CV joint and the wheels, any issue with these joints could endanger the rotation of the wheels.

Rzeppa Constant Velocity joint by Nutzdatenbegleiter / CC BY-SA 3.0. You might hear CV joint noises when braking. Regardless of whether the vibrations are caused by issues with the CV joint, you should have your automobile checked out as soon as you notice them.

Even with a healthy engine, the wheel won’t turn when the CV joint wears out. When a CV joint fails in very severe cases, the wheel won’t move at all, which can be highly dangerous if you’re traveling at highway speeds.

Therefore, it is never advised to drive a vehicle that has a faulty CV joint, even if the issue is only beginning. You ought to take it seriously and replace the CV joint right now.

Even while replacing a CV joint can be pricey, especially if you need to repair many of them, the cost of putting your life at risk or needing to replace other significant suspension system parts is far higher.

How Can CV Joint Noise When Driving Straight Be Fixed?

You need to avoid potentially dangerous scenarios if you’re driving with a damaged CV joint. You should take care of any symptoms that indicate the CV joint in your car is defective as soon as you see them. To completely grasp how to identify which CV joint is defective, read our earlier articles. By being aware of these warning signs or symptoms, you can identify a defective CV joint before it requires costly repairs.

A damaged CV joint is typically caused by a busted CV joint boot. You can easily replace your boot and lubricate your CV joint with high-quality lubricants if you catch a defective CV joint boot in your car before it damages your joint. Your CV axle or joint does not need to be completely replaced. The cost of replacing a CV boot is reasonable; it is not an expensive component to buy. New clamps and high-quality grease are typically included with new automotive CV joint boots.

You will have to pay a mechanic’s labor price to assist you if you do not know how to replace this on your own.

However, suppose the CV joint in your car is broken. It must be changed out for a new joint. This is due to the inability to manage or heal a damaged CV joint. In most cases, you cannot buy a CV joint alone. The whole driveshaft will need to be purchased.

If this is the case, we can assist you to avoid paying labor charges by demonstrating how to restore your CV joint and stop that annoying noise:

For this repair, you must put on your safety gear. When discussing auto repairs, we usually emphasize this point. After securing your gear, move your toolbox of mechanical equipment close by and turn your lug nuts by roughly a quarter before lifting your car off the ground.

Check to see if your wheel has an axle nut located directly in the middle, as this must be removed before removing the lug nuts on most vehicles. If your car has an axle nut, you’ll need to remove the cotter pin from it to perform this. The cotter pin has folded back ends to hold it in place and resembles a bobby pin. You’ll need to use pliers to straighten your pin’s crooked ends so you can remove it more quickly.

Applying lubrication will help you pull the cotter pin off if it is proving to be tough to remove.

You can now take off the axle nut after properly removing your cotter pin. Please be aware that it is much safer to raise your vehicle before removing the axle nut. Vehicles typically have several axle nut sizes. To enhance your chances of finding the appropriate size for your car, make sure you have a variety of socket sizes.

Now is the time to elevate your car. Either use a jack or a car lift to accomplish this. Both of those choices are wise. Make sure you are familiar with how to use the choice you chose. If you’re using a jack, see the manufacturer’s manual for your car for advice on where to set it. Before raising your car, don’t forget to put it in park mode and press the brake. After lifting, position your vehicle on the jack stands.

Imagine that you choose to employ an automobile lift, which is a more simple strategy. To avoid improper installation, double-check the manufacturer’s instructions for the ideal location to fix the lift adaptors. Lift your car, remove all of the lug nuts, and then take the wheels off. To view under your automobile, use a suitable work light.

Your brake rotor and caliper will be visible once your wheels have been removed. Your brake caliper housing is a substantial portion that is affixed to the rotor’s exterior. The mounting bolts for the brake caliper are located in a bracket. The configuration is determined by the model of the car. Because your brake caliper is attached to your brake line, you should lock it in place rather than letting it hang.

The caliper can be kept out of the way by being hung from a short cord. By doing so, you spare your brake line stress. You will notice brake fluid dripping from the brake line if your brake line separates from your brake caliper. You will be compelled to begin the entire brake bleeding procedure as a result of this flow.

The tie rod must now be separated from the steering knuckle. Typically, your steering knuckle, which you can find at the back of your rotor, is where your outer tie rod is fastened. Similar to the axle nut, this bolt occasionally has a cotter pin. If the cotter pin is very difficult to remove, try using a penetrating lubricant. Even once the bolts are removed, it could be difficult to remove your tie rod.

To remove the tie rod, whack the steering knuckle where the tie rod enters with a hammer. Do not strike your tie rod’s threaded portion.

Your strut tower’s hub should be removed. Typically, your hub and strut tower are connected by two nuts. As soon as the bolts are removed, you will notice that the hub is only connected to the axle via the central hole. Now, it ought to be simple for you to remove the hub. Keep in mind that you will need to hold your bolt’s head in place as you unscrew the nut. It won’t come off if you don’t.

To pry into your CV joint, use a screwdriver or any other kind of pry bar. The location where your axle is attached to the transmission can be found by following the back of it. If your axle does not come off right away, try twisting your pry bar to make it brake. As you remove your axle, some transmission fluid may start to leak; this is typical. A can should be placed beneath the leak.

For the majority of automobiles, you must first slip the axle through the wishbone to fully remove it. It also helps the axle come off more quickly if you remove the band from your inside boot.

Insert your new CV axle into the transmission housing. The method you used to remove your old axle should be followed here.

The new axle may be swiftly installed in the same position using a CV joint boot clamp tool. The procedure of tightening the CV boot clamp will be greatly aided by this instrument. When the new axle settles into place, you should hear the tiny c-clip snap. If placing your axle is difficult, you should use a mallet, ideally made of rubber, to strike it into place.

The axle must now be inserted into the hub assembly center. Reassemble the components exactly as you had removed them. You can begin with the hub assembly before moving on to the strut tower. Make sure all of your loose bolts are tight. Connect your brake caliper once you have secured the outer tie rod into your steering knuckle. If you notice any worn-out cotter pins. Please swap them out.

Heavy duty car axle by Kure / CC BY-SA 2.5. The boots on the CV joint hold the grease in place while the axle rotates. The CV joint boots prevent grease from leaking out during this spinning.

Put your wheels back on and tighten your lug nuts a little. Your car can then be lowered till it hits the ground. Before lowering, take off the jack stands. Tighten your axle and lug nuts once your car is on the ground.

Before making any repairs to your CV joint, please make sure you understand how to distinguish between a poor wheel bearing and a defective CV joint. You may count on us for assistance with this.

What Is the Cost of Replacing a CV Joint?

Depending on your vehicle’s make and model and the shop you choose, replacing a CV joint typically costs between $95 and $210.

The cost of hiring a qualified mechanic to fix your car’s CV joint could range from $165 to $800.

Naturally, the cost can increase if you intend to replace double joints, and labor is a significant factor in the total cost of CV joint replacement.

For instance, you might spend roughly $400 if you decide to replace two CV joints at once. Keep in mind that these figures just cover the part itself; if you also want to have the two joints replaced, expect to pay between $800 and $1200.

In other cases, the CV joint may not even be harmed; instead, it may be the CV boot that is the issue. If that’s the case, the cost of a replacement might range from $250 to $300 for parts alone. The cost of your labor could be between $550 and $650.

As you may have noticed, labor makes up the majority of the cost of replacing a CV joint. You should therefore use caution when deciding whether to visit a dealership or a small repair business.

Even though it will cost them substantially more in labor, many owners of newer vehicles prefer to go to the dealership since they know that the work will be done by qualified mechanics, eliminating any chance of causing significant damage or other difficulties.

How Difficult Is It to Replace a CV Joint?

It shouldn’t take more than four hours to replace both CV joints. However, if you intend to replace the CV joints by yourself, the procedure can take longer since you will need to comprehend and become familiar with the proper methods for placing them.

Another thing to consider is that even if you will have to wait a little while for a technician to complete the task for you, it is a little safer because the mechanic is an expert at what he does. The likelihood of introducing measure harms is relatively low because he has probably already done it.

On the other hand, there is a good risk that any DIY you try on your car won’t work the first time, and you might add some other difficulties that end up costing you more money in repairs.

This is not meant to dissuade you from changing your CV joints; rather, it’s more of an evaluation process to understand the primary benefits and drawbacks of performing the task yourself before attempting to do so.

Use a hammer to strike the steering knuckle where the tie rod enters to remove the tie rod for repairing CV joint noise when driving straight. Avoid striking the threaded part of your tie rod.

What Happens If Bad CV Joints are Not Replaced?

You cannot put off replacing the CV joint for a few months; you must do it as soon as you have the time. If things become too convoluted, your car can stop working and be unable to move.

As we previously mentioned, the CV joint could rupture severely and prohibit the wheels from turning at all. As a result, not only will you endanger your life, but it’s possible that you won’t even be able to move this car.

To avoid getting stuck somewhere without access to close assistance, it is advised that you address any indications of a poor CV joint as soon as possible.

Is Driving with a Bad CV Joint Safe?

Making a clicking or popping noise when turning or making a sharp turn is a sign of a severely worn-out CV joint. Driving with a worn-out CV joint is possible, but there is no proof that it is safe or durable for a long time.

The worst-case situation is CV joint failure, which will shatter the axle and finally prevent your automobile from moving. It is possible to drive for a time with a faulty CV joint, but it is not completely safe. The clicking sound is primarily associated with a damaged CV joint.

You should be aware that if you keep driving with a noisy CV joint, you could end up completely ruining the joint. As a result, you should be able to test CV joints.

How Much Longer Can a Bad CV Joint Last After It Begins to Make Noise?

For a period of four to five months or somewhat longer, it might be safe to drive with a damaged CV joint. You should take your car to a mechanic when the six-month mark is nearing to have the defective part replaced or fixed. After six months, it is unsafe to keep utilizing the worn-out or injured CV joint.

For people who live in dry places with little rain, this six-month time may be completely safe for them. However, for those who live in wet areas, learning how to check a CV joint for play should not be an option.

If you don’t know how, go to a mechanic before this period expires, at least for the first three months, since it will be best to know how to do this on your own given the amount of sticky mud, rain, dirt, and even snow.

A wheel with a car tire by Daniel Case / CC BY-SA 3.0. The wheels might become completely immobile if the CV joint were too badly torn. You’ll not only put your life in danger but, probably, you won’t even be able to move this car as a result.

The Conclusion

One of your car’s most crucial parts is the CV joint. It is in charge of making sure the wheels always rotate at the same speed.

The CV joint may become worn down over time as a result of cracks in the CV joint boot or inadequate lubrication. You will hear strange noises when this occurs in specific circumstances.

A very common sign of a problem with the CV joint is a clicking noise. The problem may vary based on the circumstances. A clicking sound, for instance, may be made when turning, driving straight, braking, etc.

The cost of replacing a CV joint is expensive, especially if you want to replace several joints at once.

When traveling straight, CV joint noise can be quite uncomfortable and grating. You must understand how to solve this as quickly as feasible because of this.

Make sure you always take safety measures when working underneath your car. To ensure you complete this repair safely, make sure you have your brakes in park mode and have taken additional preventative measures.

Rzeppa Constant Velocity joint by Nutzdatenbegleiter / CC BY-SA 3.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”