There could be several reasons why the performance of your older vehicle isn’t what you’d expect. One such part is the carburetor. Although they are still employed in certain older cars, carburetors are no longer used in many modern autos.

In cars from the middle of the 1970s and before, such as vintage or show cars, a carburetor efficiently started and ran the vehicle. Such carburetors would mix the right amount of gasoline and air before supplying it to your engine for internal combustion.

Due to their ability to ensure that an automobile ran at peak efficiency without being too rich or lean, such carburetors became the most important component. Although modern automobiles no longer require carburetors due to better technology, there are still thousands of cars on the road that rely on them.

Carburetors can degrade or malfunction, just like any other auto part, preventing the vehicle from operating as intended. This is why automobile owners must be aware of the signs of a bad carburetor.

The following are indicators you may check to see if you are experiencing any signs of a bad carburetor so you can get your automobile serviced right away before the problem becomes worse.

A Carburetor: What Is It?

The carburetor is in charge of mixing gasoline and air in the right amounts and managing engine speed. Your carburetor is one of the components that help keep the air/fuel ratio in balance when a precise ratio of the two must be kept. Your carburetor is also in charge of controlling engine speed.

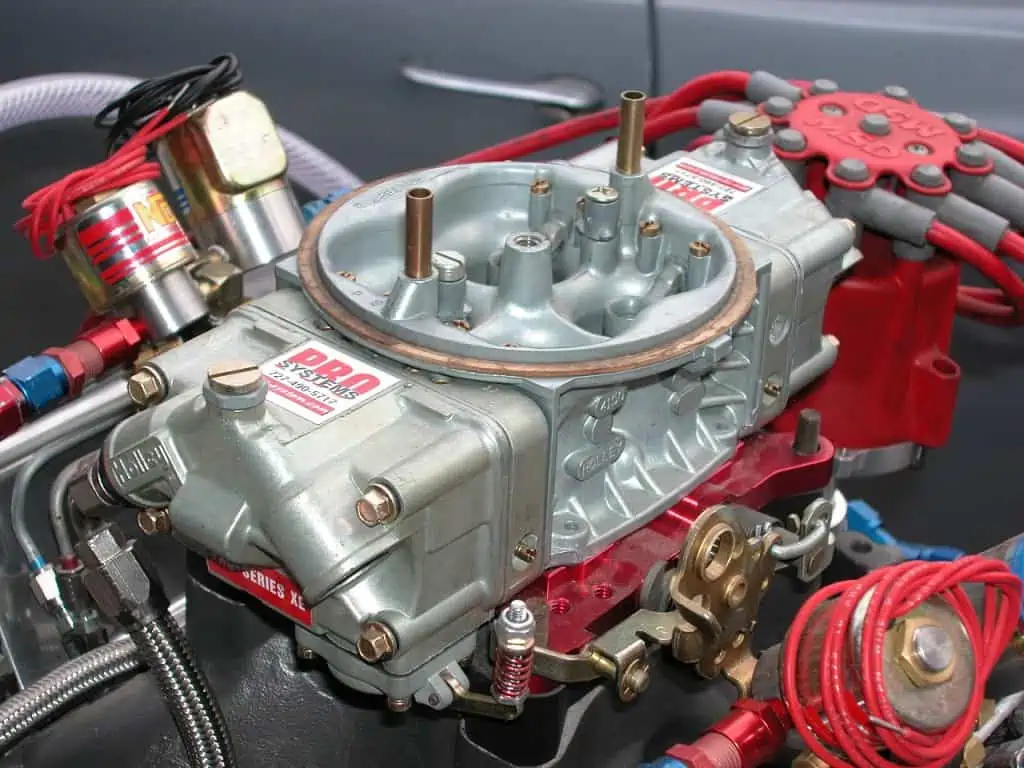

Today’s cars use one of three different types of carburetors. They come equipped with a one-, a two-, and a four-barrel carburetor. The type of carburetor needed depends on your vehicle’s engine setup. Higher-performance engines frequently require many carburetors to provide the right amount of gasoline.

A high-performance 4-barrel carburetor by Rich Niewiroski Jr. / CC BY 2.5. Like any other motor component, carburetors can wear out or malfunction, stopping the vehicle from running as it should. Because of this, car owners need to be aware of the symptoms of a faulty carburetor.

What Is a Carburetor’s Working Technique?

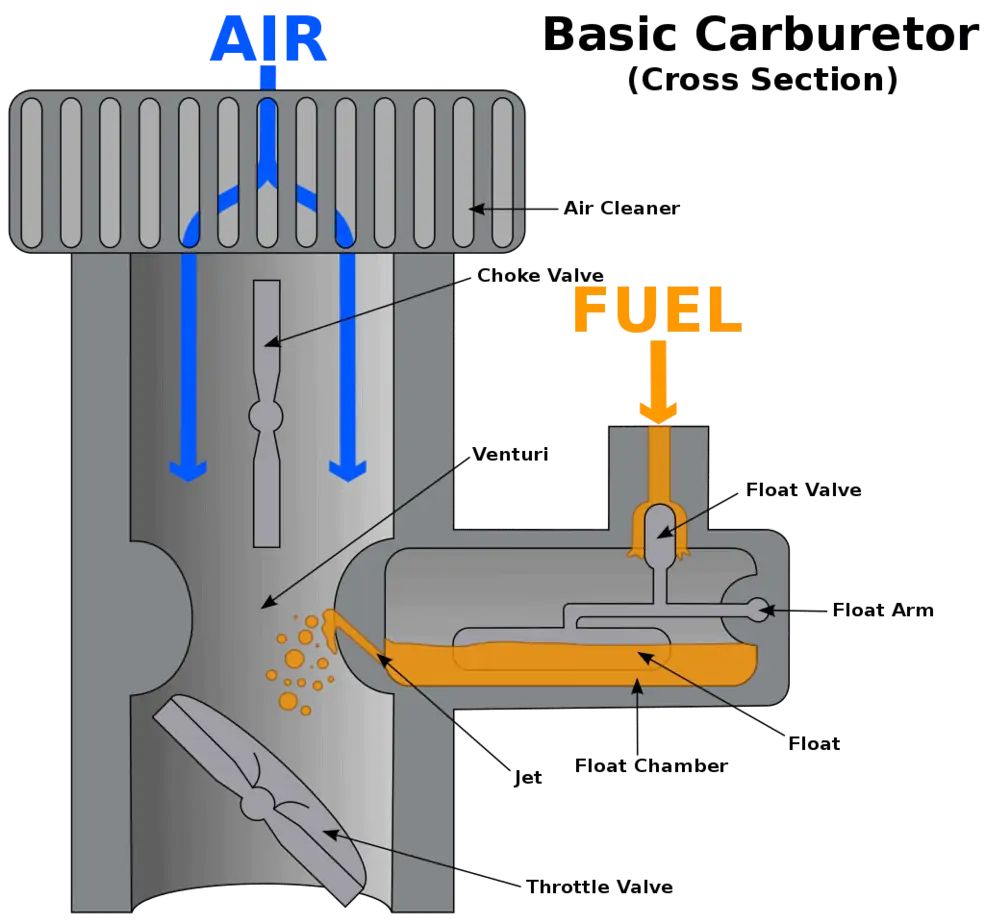

The complexity and design of carburetors vary widely. The most straightforward one is a sizable vertical air pipe above the engine cylinders with a horizontal fuel pipe attached to one side.

The air needs to squeeze past a little bend in the middle of the pipe as it travels downward, which accelerates it and lowers its pressure. A venturi is a name for this curved portion. Air is drawn in through the fuel pipe on the side by a sucking force caused by the air pressure dropping.

We need the fuel to be drawn into the airflow to join it, but how can we change the air-fuel ratio? Two swiveling valves are located above and below the venturi on the carburetor. The choke, a valve at the top that controls how much air may enter, is there.

When the choke is closed, less air travels through the pipe and more gasoline is drawn in by the venturi, giving the engine a fuel-rich mixture. That comes in helpful when the engine is cold, just beginning, and moving slowly. A second valve known as the throttle is located below the venturi.

More fuel is drawn in from the side pipe as the throttle is opened further, allowing more air to travel through the carburetor. The engine produces more power and energy with more fuel and air entering it, which causes the vehicle to move more quickly.

Opening the throttle is similar to blowing on a campfire to add more oxygen and speed up the burning process, which is why doing so causes a car to accelerate. In a car or a motorcycle, the throttle is connected to the handlebar or accelerator pedal.

The gasoline entrance to a carburetor is a little more intricate than we’ve previously detailed. A small fuel tank known as a float-feed chamber is attached to the fuel pipe (a little tank with a float and valve inside it).

The fuel level drops as the chamber feeds fuel to the carburetor, and the float drops along with it. A valve that allows fuel to be poured into the chamber from the main gas tank is opened when the float falls below a predetermined level. When the chamber is full, the float rises then closes the valve and switches off the fuel feed once more.

The float-feed chamber functions somewhat similarly to a toilet, with the float serving as the ballcock’s replacement—the valve that ensures that the toilet refills with the proper amount of water after you flush. What do toilets and vehicle engines have in common? More than you may have imagined!

So here’s the overall process, in summary:

- The air intake of the car sends air into the top of the carburetor, where it passes through a filter to remove particles.

- To restrict the amount of air entering the engine when it initially starts, the choke (blue) can be adjusted such that it almost completely blocks the top of the pipe (increasing the fuel content of the mixture entering the cylinders).

- The air is driven via a small bend known as a venturi near the tube’s middle. It accelerates as a result, and the pressure decreases.

- Suction is created on the fuel line (right) as a result of the drop in air pressure, drawing fuel in (orange).

Cross-sectional schematic of a carburetor by K. Aainsqatsi / CC BY-SA 2.5. The carburetor controls engine speed as well as how much gasoline and air are mixed. When an exact ratio of the two must be maintained, it is one of the elements that aid in maintaining the air/fuel ratio in balance. The carburetor in your vehicle is also in charge of regulating engine speed.

- The green throttle is a valve that can be rotated to open or close the pipe. More gasoline and air are delivered to the cylinders when the throttle is opened, which increases engine output and accelerates the vehicle.

- Air and gasoline are combined as they descend into the cylinders.

- The float-feed chamber, a tiny fuel tank, provides the fuel (orange).

- A float in the chamber descends as the fuel level drops, opening a valve at the top as it does.

- More gasoline from the primary gas tank enters the chamber when the valve opens, replenishing it. The float rises, as a result, closing the valve once more.

What are the Signs of a Bad Carburetor?

Understanding the signs of a bad carburetor is essential to avoiding costly, pointless repairs. Additionally, it’s critical to treat the problem right away because a faulty carburetor may trigger a chain reaction of issues that could endanger your engine. The most typical signs of a bad carburetor are listed below.

1. Engine Performance Drops

Your car may have a defective or failing carburetor if it doesn’t seem to have the same amount of power or engine performance as it once did. This is because your engine’s carburetor distributes and evaluates a fuel/air combination.

Your engine needs this air and fuel to run at its best. If your car’s carburetor is broken, you won’t just lose power; you might also find that you’re using more fuel than usual and that acceleration is poor.

2. Engine Backfiring or Overheating

The common signs of a bad carburetor are engine overheating and backfiring. Engine overheating or backfiring may occur if the carburetor has a problem that causes it to deliver a lean mixture, a fuel-air mixture with a low amount of fuel.

Lean mixes are poor for engine performance and, in more extreme circumstances, can seriously harm the engine in addition to overheating or backfiring.

3. Dark Smoke Emerging from the Exhaust

Black smoke rising from the exhaust is one of the most typical signs of a bad carburetor. When there is black smoke coming from the exhaust, the engine is burning or utilizing too much fuel.

In addition to burning unneeded gasoline, a carburetor that is supplying too much fuel to the point of black smoke is also emitting too many unwanted pollutants.

4. Difficulty Starting the Car

Starting difficulties are other typical signs of a bad carburetor. The appropriate air-fuel ratio, which is crucial and delicate during cold starts, is maintained by the carburetor through blending and metering.

The 2-barrel carburetors by Lothar Spurzem / CC BY-SA 2.0 de. To prevent expensive, unnecessary repairs, it’s critical to recognize the symptoms of a malfunctioning carburetor. It’s crucial to address the issue as soon as possible since a malfunctioning carburetor may set off a series of problems that could jeopardize your engine.

Hard starting could occur if there is a problem with the carburetor that alters the air-fuel ratio. The car may be difficult to start and get easier as the engine warms up, or it may remain difficult to start even after the engine has warmed up, depending on the severity of the issue.

5. Car Experiencing Harsh Idle

The majority of the time, a lean fuel mixture that causes lean misfires causes a rough idle state. Air leaks in vacuum lines, the EGR valve, the PCV system, and air leaks between the carburetor and intake manifold are frequently to blame for idle issues.

A too-lean idle mixture adjustment setting is another carburetor-related fault that can be fixed by pulling out the screw one-quarter turn at a time until the idle quality improves.

A dirty idle mixture circuit may also be the problem, and the carburetor may need to be cleaned and rebuilt.

Although less frequent, other potential reasons for a rough idle include a broken charcoal canister purge control valve that is allowing gasoline vapors to seep back into the carburetor.

Other factors that contribute to a trough idle include an excessive amount of compression blowby, weak or broken valve springs, ignition misfiring due to dirty or old spark plugs, defective plug wires, or a weak ignition coil.

6. Sluggish Acceleration

Delay or reluctance when accelerating is one of the most obvious signs of a bad carburetor. This is typically brought on by an excessively lean fuel mixture, which means there is too much air and not enough fuel.

A poor air/fuel mixture may be caused by worn throttle shafts, weak or malfunctioning accelerator pumps, or carburetor debris.

7. Under Load Hesitations

A malfunctioning power valve, often known as a hesitation, can be the cause of a stubble or misfire that occurs while the engine is under stress. A carburetor pulls fuel through its metering circuits using an intake vacuum.

The vacuum decreases as the engine load increases and the throttle open wider. The fuel-air mixture may become too lean as a result, thus the power valve contains a vacuum-sensing diaphragm that springs open to increase fuel flow when the vacuum falls.

It must be replaced if the diaphragm has failed or if the valve is clogged with fuel varnish deposits or debris.

A carburetor rebuild kit typically includes a new power valve. Additionally, a weak ignition coil, a cracked ignition coil, a disturbed ignition cap, and occasionally defective spark plug wires can cause hesitation or misfiring while the engine is under load.

8. Stalled Engine

The engine can stall when it is cold if the idle speed is not adjusted high enough. If the idle speed is too low, the fuel is tainted with water or alcohol, or there is not enough fuel pressure to keep the carburetor bowl filled, the engine may stall even after it has warmed up.

A hot or cold stalling issue can typically be resolved by adjusting the rapid idle, regular idle speeds, and idle mixture modifications.

9. Flooded Carburetor

Although the carburetor is frequently to blame for this issue, it is not always the case. The carburetor may flood if dirt gets into the needle valve and stops it from shutting.

The bowl overflows and pours fuel into the throat of the carburetor or out of the bowl vents if this issue is not rectified right away and there is no way to stop the flow of fuel. An engine that has been flooded might not start because the spark plugs are soaked with petrol.

Flooding may also happen if the fuel bowl’s internal float is set too high or develops a leak and sinks. In this instance, a new float is all that is required; the carburetor does not need to be replaced. Since rebuild kits don’t come with floats, a rebuild kit must also be obtained if new gaskets are also needed.

Flooding can also result from high fuel pressure, which pushes the fuel beyond the needle valve. Flooding may occasionally result from too much heat. A jammed heat riser on a V6 or V8 engine can form a hotspot under the intake manifold, which can lead to the fuel in the carburetor bowl boiling over and flooding the engine.

Precaution: Flooding can be extremely dangerous since it poses a severe fire risk if fuel leaks from the carburetor on an extremely hot engine.

10. Too Fast Idles

This particular idling problem is typically brought on by an automated choke. If the choke is only slightly stuck and is not fixed straight away, dirt can accumulate until the choke is solidly stuck. It is wise to inspect the choke and the choke linkage, clean them as necessary, and make any necessary repairs.

Engine speed is controlled while the engine is warming up by a separate quick idle adjustment screw on the choke linkage.

As the choke opens during engine warm-up, the screw’s tip rests on a cam that slowly rotates. To slow down the fast idle speed, turn this screw in the other direction. However, simply move the screw in a clockwise direction to increase the rapid idle speed.

Vacuum leaks that let air into the manifold can also cause a high idle speed. A defective idle speed control valve that is stuck in the extended or high idle speed position can also be the cause.

11. Lean Engine Condition

Another usual sign of an unclean or malfunctioning car carburetor is when the vehicle runs low. Your car is tilting if it makes a noise akin to someone sneezing.

A lean fuel mixture indicates that your carburetor isn’t receiving enough fuel from the engine, which throws off the balance of the 12:1 air/fuel ratio. Your engine will run lean if the balance between the air/fuel ratios is off.

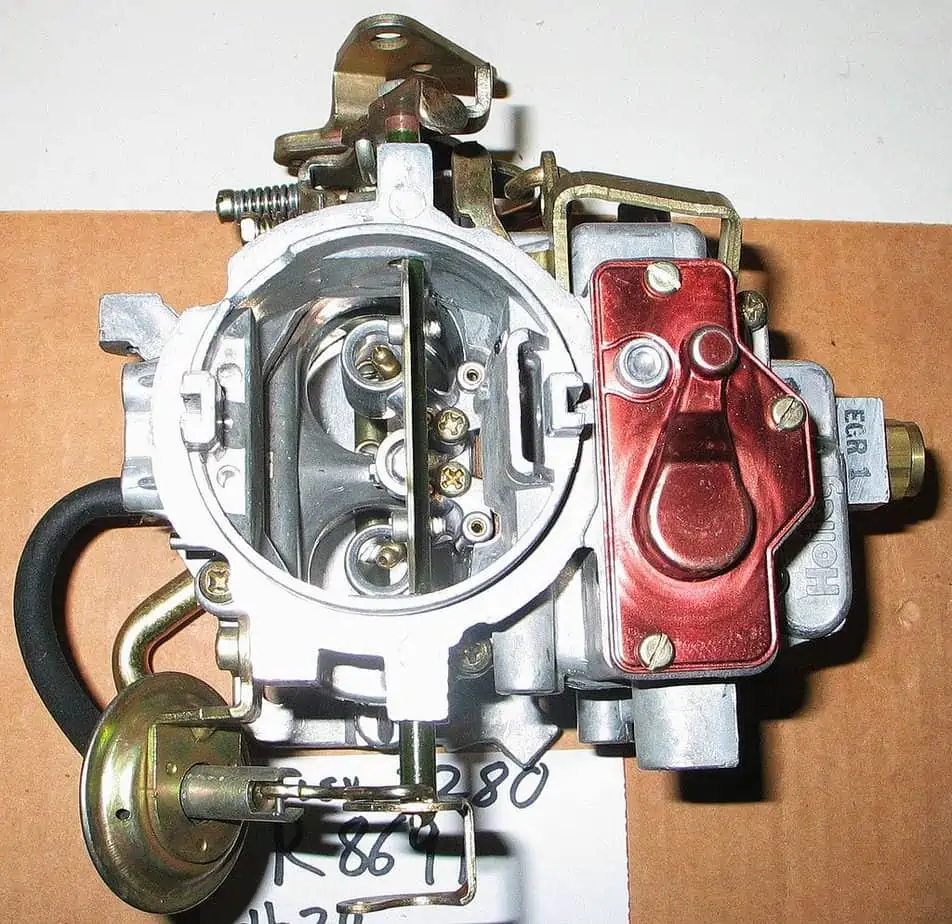

12. Rich Engine Condition

The engines starting to run rich are other signs of a bad carburetor. When the carburetor has a rich fuel mixture, there is either not enough air or too much gasoline present.

If you observe black smoke coming from your tailpipe, this means your carburetor has a rich fuel mixture and is burning the extra fuel, which produces the black smoke.

A typical car engine by Carolla / CC BY-SA 3.0. Other symptoms of a malfunctioning carburetor include the engines starting to run rich. A rich fuel mixture in the carburetor means that there is either insufficient air or excessive gasoline.

NOTE: Although they are no longer commonly used, carburetors are still present beneath the hood of many road-worthy automobiles and trucks, and they play a crucial role in maintaining the drivability and performance of the vehicles that are fitted with them.

To find out whether your automobile needs a carburetor service or replacement, get the vehicle evaluated and thoroughly diagnosed by a skilled technician, such as one from your dependable service facility or repair shop if your carburetor is displaying any indications of wear and tear or you have the impression that your carburetor may be having problems.

What Should I Do If My Car Shows Signs of a Bad Carburetor?

The carburetor has a lot of effects on older cars, therefore it’s important to solve the issue right away! To correctly identify and resolve the problem, the carburetor must be inspected or serviced by an expert. When it comes to fixing a broken carburetor, there are several alternatives available.

1. Make the Carburetor Clean

Using a powerful carburetor cleaner to clean your carburetor is one of the first things a mechanic would perform. Your carburetor frequently malfunctions as a result of dirt or debris getting into its interior parts and obstructing the jets or floats.

This prevents your carburetor from giving your engine the essential fuel/air mixture, which results in several automotive problems. The carburetor will be dismantled and cleaned with a carburetor cleaner to get rid of any undesired particles to fix the issue.

2. Carburetor Replacement or Rebuild

If you believe that your carburetor requires repair, take care of it as soon as you can. It can be replaced with a new or refurbished carburetor or rebuilt using a kit. Depending on the kind and use of the carburetor, replacing one can cost anywhere from $200 to $600 or more.

Cleaning and rebuilding an older single or two-barrel carburetor is a fairly easy task. However, cleaning and rebuilding a four-barrel type can be very challenging. More challenging carburetors might necessitate the expertise of a specialist or perhaps a professional mechanic.

Most of the time, replacing a more intricate carburetor is simpler and safer than attempting to repair it. Consult a specialist if your carburetor has variable-venturi or electronic feedback controls and tamper-resistant settings.

Your carburetor cannot be repaired if it has fractured castings, worn throttle shafts that are leaking air, or damage to any or all of the castings. The only solution in this situation, if this is the case, is to have a second carburetor that you can salvage, disassemble for parts, and then utilize to fix the first one.

You must first identify a carburetor before you can rebuild or replace it. The carburetor typically has a small metal ID tag that contains all the information you need, including the precise model number and calibration of the device, to locate the right carburetor kit or new carburetor.

Carburetor Setup Changes

Modify your engine’s idle mixture adjustment screws and idle speed when it reaches the typical operating temperature. Set the idle mixture screws for ideal idling and the standard idle speed (usually 600 to 650 rpm).

If you see black smoke coming from the exhaust, your carburetor is burning the additional gasoline since it has a rich fuel mixture. This is what causes the black smoke.

Once your engine begins to sputter, turn each idle mixture screw in until it is out by a quarter to a half turn. Continue adjusting your idle for the best ride.

When your engine doesn’t start properly, its automatic choke may also need to be adjusted. When the engine is cold, the choke must be completely closed; once the engine has warmed up, it must be fully open.

Small modifications can go a long way, so it might take several trial-and-error tweaks to get the choke housing just right.

Your engine’s accelerator pump linkage or cam may also need to be modified if it stumbles or hesitates when accelerating to increase the amount of fuel that is sprayed into it whenever the throttle is opened.

If you have a lot of adjustment possibilities for your cam or accelerator pump linkage, try the following higher setting.

Which are the Available Strategies for Rebuilding Carburetors?

Make sure to have a service manual assembly diagram handy before disassembling a carburetor. Some kits for carburetors don’t come with instructions or an installation schematic. Additionally, keep in mind how the various vacuum hoses and pipes link to the carburetor. If necessary, identify the hose connections or draw a picture of them.

On a spotless workstation, metal tray, or piece of paper, assemble your parts. When you put the carburetor back together, remember how the pieces were disassembled so you can put them back together correctly. Be careful not to misplace the tiny check balls.

Use a solvent or cleanser for your carburetor that won’t harm soft metals or plastic. To avoid coming into contact with the cleaner or solvent on your skin, put on some rubber gloves. Follow the instructions carefully and be sure to clean in a well-ventilated location to prevent breathing in fumes.

Check to see if the throttle shaft is worn. A worn throttle shaft hole allows air to get through the shaft and lean out the fuel mixture. To resolve this problem, take out the throttle shaft, enlarge the hole, and then add a steel or brass sleeve to restore the proper clearances.

A bad float within the fuel bowl is another thing to look out for. Shake brass floats to see if there is any liquid inside. A tiny hairline seam break allows fuel to seep through, sinking the float and overloading the engine with fuel as a result.

The issue with plastic floats is that they gradually absorb fuel, which causes them to ride too low in the fuel bowl and flood the engine with fuel. The problem could be resolved by swapping out a damaged float with a new one.

Which are the Available Strategies for Installing a Carburetor

Clean the intake manifold mounting surface before replacing the gasket underneath the carburetor (No dirt or gasket debris should get inside the manifold).

The old gasket shouldn’t be used again because it almost always leaks. To reduce the likelihood of air leakage, you can use a gasket sealer, but you should never use RTV silicone since it dissolves when it comes into touch with gasoline.

Replace the gasket. To ensure that the gasket is securely fastened in place, make sure the carburetor base mounting nuts or bolts are tightened consistently. Never overtighten the fasteners as this could cause the carburetor base plate to break or distort.

When reattaching the fuel line and any additional fittings like the EGR and the PCV valve, take care not to cross-thread the fittings. Never tighten a casting too much since doing so could strip the threads.

Install a fresh fuel filter to shield the carburetor from debris.

Make that the throttle linkage’s return spring(s) are reattached. When you start it up, you don’t want to wind up with a runaway engine. When springs become rusted and worn, replace them with new ones. Additionally, make sure the throttle linkage is in good working order.

Avoid overtightening the nut holding the air cleaner in place when installing it because doing so could harm and deform the carburetor’s casting.

Verify all gasoline hoses and clamps. Clamps should be replaced (the best option: is worm-screw clamps). A worn-out hose should be replaced if it is fractured, leaky, brittle, hard, or mushy.

Double-check the connections of the fuel line, throttle linkage, vacuum, exhaust hoses, and return spring. Activate the engine. Check again for any new problems or leaks.

How Much Do Signs of a Bad Carburetor Repair Cost?

Your technical prowess, financial resources, time availability, and the severity of your carburetor issues will determine whether you should replace or rebuild it. Always research how much a brand-new carburetor will cost.

Sometimes, spending a few more dollars on a replacement carburetor part might save you the time and labor-intensive task of maintaining and cleaning your old carburetor.

1. Replacing the Carburetor

Your carburetor should be changed if it has considerable damage or deterioration that cannot be fixed by cleaning or reconditioning.

The cost of replacing a carburetor ranges between $20 and $200 for a DIY fix. and $20 to $200 per component plus $70 per hour for a professional fix.

2. Rebuilding the Carburetor

A carburetor rebuild kit can revive your carburetor by providing new gaskets and several necessary parts. Make sure you always purchase the appropriate carburetor kit.

The cost of rebuilding a carburetor ranges between $10 to $60 for a DIY fix, and $10 to $60 per chunk plus $70 per hour for a professional rebuild.

The Conclusion

It’s important to take your automobile to a mechanic as soon as you discover any of the aforementioned signs of a bad carburetor. It is costly to ignore these signs of a bad carburetor.

Your car’s fuel economy will be negatively impacted by a damaged carburetor, which means you’ll end up paying more at the pump. An improper fuel/air combination could result in engine failure.

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”