We can claim with certainty that an engine’s nearly every component is significant. Your car’s entire motor might not even function properly without either one or the other element.

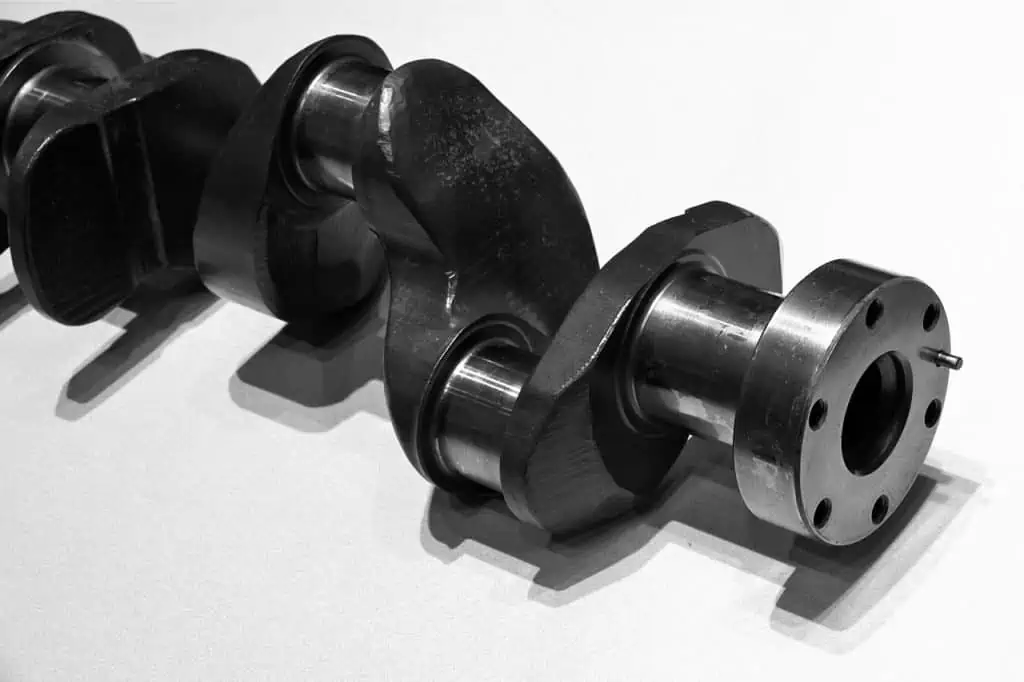

The crankshaft is critical to your engine function. Your engine’s numerous booms and explosions wouldn’t produce any movement without it. Crankshaft repairs are therefore essential when necessary.

A crucial component of your car, the crankshaft, will harm other parts if it is not maintained and repaired as needed. In the majority of cases, you will also need to get the engine ready. This may be far more expensive and raise the entire cost of the crankshaft repair.

One of the most expensive and time-consuming issues with your car is this one. Try to maintain the crankshaft in the best shape you can to prevent this. If not, you should budget around $2014 for the overall cost of the crankshaft repair.

But why does this matter with a part that is often tucked away inside an engine? Additionally, some people question if crankshaft repairs can be done or if a more expensive replacement is the only option for a broken crankshaft.

We want to provide answers to these queries. While doing so, we’ll also look into the process of crankshaft repairs to determine their value.

A Crankshaft: What Is It and How Does It Work?

It would be beneficial to have a better understanding of the function of the crankshaft before beginning any repairs. So what function does your car’s miraculous crankshaft serve? What role does it play?

We all know that engines work by burning a mixture of compressed fuel and air to produce power. But how does that movement come about from that ignition? The crankshaft, a friend of ours, can assist us in this situation.

A car crankshaft by Alex Kovach / CC BY 2.0. One of the parts in the hall of fame for how well your engine runs is the crankshaft. Without it, none of the booms and explosions from your engine would move. When necessary, crankshaft repairs are consequently crucial.

The force pulls the pistons up and down inside the cylinders as numerous controlled explosions occur repeatedly inside the combustion chamber of your engine. Reciprocating motion is the name for this upward and downward motion.

Unfortunately, it is not possible to efficiently convert the reciprocating action of several pistons that explode at different intervals into energy that could smoothly move the wheels.

Therefore, the function of the crankshaft is to convert the reciprocating action into a useful rotating motion. The crankshaft, as its name suggests, is a “shaft” that is propelled by a “crank” mechanism.

Where the pistons are located at the bottom of the engine is the crankshaft, which is connected by connecting rods. The crankshaft is then attached to the flywheel once the pistons have begun to be converted into rotational motion.

The flywheels aid in minimizing any vibrations or pulsations. Later on, the crankshaft’s rotational motion could be transferred to the transmission by this flywheel.

The gearbox in your car will now be able to convert the motion into power that will effectively move the wheels. causing your car to move. All in all, a key element in making it all work is the crankshaft.

Do Crankshafts In Old and New Cars Differ Much?

Interestingly, modern cars are significantly less likely than older cars to sustain crankshaft damage or failure for a very straightforward reason. As we’ve seen, low oil levels or poor maintenance are the main causes of crankshaft repairs.

Numerous sensors in contemporary cars can notify us when an oil change or other maintenance is necessary. However, older cars didn’t have this privilege.

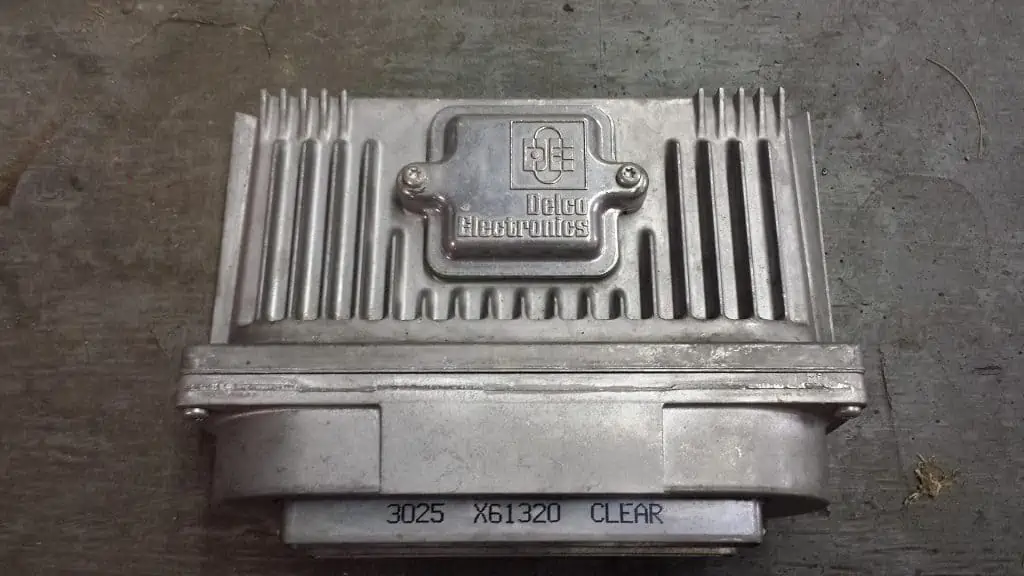

Therefore, more current cars may, for example, get a signal from their sensors to operate in limp-home mode. When these sensors and the ECU have discovered any sort of issue, the work output of the engine is reduced.

Any potential full failure of the crankshaft may be prevented by reducing the workload as a whole. On the other hand, older vehicles could continue to run until the crankshaft fails.

Mind you, there is another side to this story. Crankshafts today are capable of supporting greater loads. For instance, a crankshaft in certain modern diesel engines may withstand loads of 10,000 kg. Ten tonnes, or around 22,000 pounds, are being exerted on the crankshaft.

Imagine having four, six, eight, or twelve connecting rods linking the pistons to the crankshaft as this is only for one.

However, there is also a case that can be made for older crankshafts being stronger. Recently, several automakers have shifted their focus toward efficiency, and weight reduction is one of the compromises made.

For instance, several modern vehicles use aluminum crankshafts instead of cast iron. Even though it might be lighter, a solid billet of iron is undoubtedly more durable and bulletproof.

What Symptoms Should You Look Out for Before Contemplating Crankshaft Repairs?

Unfortunately, the warning signs that your crankshaft needs repairs are subtle and might be mistaken for other problems. Once more, crankshafts are not one of the replaceable car parts that occasionally need to be replaced.

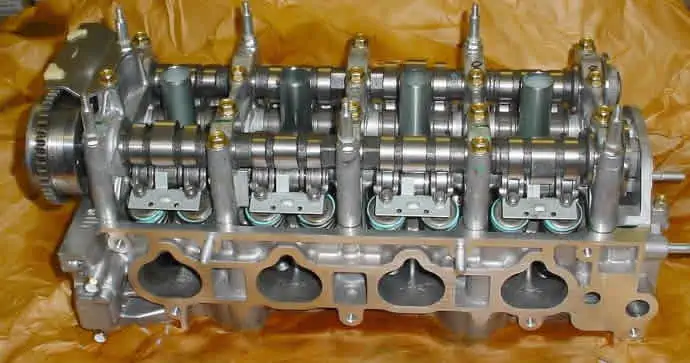

A car engine by Kether83 / CC BY 2.5. It is possible to fix the crankshaft issue without repairing or replacing the engine. An engine replacement for the majority of cars can cost between $3,000 and $4,000. Prepare to spend up to twice as much for a premium or larger vehicles.

The majority of individuals won’t ever need to worry about crankshaft repairs because they are built with longevity in mind. However, they do happen occasionally.

How can you determine when you need urgent crankshaft repairs made because these flaws are unexpected? The car will display a few indications if the crankshaft is operating improperly.

These shouldn’t be disregarded because there is still time to have them rectified if they occur. If not, and if you ignore crankshaft repairs, you can wind up having to spend much more money on an engine that has seized.

Here are some of the more frequent signs that prompt immediate attention for crankshaft repairs:

1. Vibrations Emanating from the Engine

Your engine may not be able to control the crankshaft adequately if you notice any vibrations coming from it. As a result, while you are driving, your engine will continue to vibrate erratically and continuously.

You may even be able to feel the vibrations in the wheel, which would allow you to identify the issue early and save money on the expense of a new crankshaft.

2. The Check Engine Light Illuminates

Crankshaft position sensors are always in communication with the engine control unit, so if the sensor malfunctions, the computer won’t get accurate data on the crankshaft’s speed and position.

The dashboard’s Check Engine indicator light may turn on as a result of this. This typically occurs as one of the initial signs of a failing crankshaft position sensor, demonstrating how early diagnosis can reduce the overall cost of replacing the crankshaft.

3. Engine Performance Issues

The engine control unit won’t receive accurate information regarding the position of the crankshaft or cylinders if your crankshaft position sensor is broken.

The ability to maintain the engine functioning at its peak performance level may be compromised as a result of a delay in the information provided to the electronic control unit’s system.

This can cause the gas pedal to hesitate or not respond at all during the wait, posing a threat to you and other motorists. You can save money in the long run by replacing this defective crankshaft position sensor rather than having to replace the crankshaft entirely.

4. Vehicle Not Starting

When the crankshaft position sensor malfunctions, the engine control unit is alerted. It may also be more challenging to start your car if the engine control unit receives a specific code that signals a functioning issue because the engine might not start as easily.

Before continuing to drive your vehicle, make sure the engine problem is fixed. Engine problems can significantly increase the cost of a new crankshaft.

The ”Check Engine Light” dashboard warning light by Wikiuser100000 / CC BY-SA 3.0. A damaged crankshaft may cause the Check Engine indication light on the dashboard to illuminate. This illustrates how early diagnosis can lower the overall cost of replacing the crankshaft by happening as one of the initial indicators of a failed crankshaft position sensor.

5. Engine Stagnation

As you may guess, the engine stalling problem includes your car abruptly ceasing to run while you are traveling.

If you do not address this problem as soon as you notice the stalling, the engine may shut off, necessitating the towing of your vehicle once it breaks down.

This will result in higher costs for crankshaft repairs when towing is added to the cost of the engine and crankshaft.

6. Misfiring Cylinders

A malfunctioning crankshaft position sensor won’t be able to provide the engine control unit with accurate information about the position of the piston.

This can result in the engine misfiring inside the cylinder chambers, with the defective crankshaft position sensor being the root cause of the problem. Future problems from a misfiring engine could result in more expensive crankshaft repairs.

Why Do Crankshafts Fail Hence Leading to Crankshaft Repairs?

A crankshaft is typically built to survive the entire life of the vehicle. As long as it has been given enough attention and regular upkeep.

Although sturdy, a crankshaft can malfunction in a variety of demanding circumstances, necessitating crankshaft repairs. The crankshaft bearings, for instance, are one of the more fragile components. They primarily aid in supporting the crankshaft.

As if that weren’t significant enough, those bearings also contribute to lessening friction between a rotating crankshaft and a stationary engine.

A routine oil change is more than sufficient to keep it operating smoothly, regardless of whether it is the bearings or the complete crankshaft. Your crankshaft is failing or has failed far too early in its lifespan for a variety of reasons, in general.

- Excessive heat exposure, presuming that the motor oil is unable to offer adequate cooling. Alternatively, if the engine overheats repeatedly.

- The crankshaft may be overstressed to the point of premature failure by high pressures or an excessive load from the engine.

- Corrosion, etching, or damage as a result of the crankshaft being exposed to engine oil that has been tainted with pollutants that may be acidic, chemical- or corrosive.

- Circulating dirty or debris-filled motor oil around the crankshaft runs the risk of damaging the bearings and other internal parts.

- The crankshaft may dry out as a result of low oil levels, which may be caused by a leak anywhere in the system. There will be several metal-on-metal contacts when this occurs, which will cause the system as a whole to wear down.

- The crankshaft might be more quickly worn out by increased friction or engine vibrations caused by improperly sized or poorly fitting bearings.

- Engine jamming, which may occur in the event of a gearbox failure, can cause the engine to stop and cause significant crankshaft wear.

- The counterweights that stabilize the crankshaft’s rotation may be loose, which would cause the crankshaft to slide out of alignment.

The engine control unit by Mgiardina09 / CC BY-SA 3.0. The engine control unit receives a warning when the crankshaft position sensor isn’t working properly. Additionally, the engine could not start as easily if the engine control unit receives a specific code that indicates a malfunction, making it harder to start your automobile.

What Kind of Crankshaft Repairs Take Place at the Auto Repair Shop?

It’s time to discuss what crankshaft repairs entail. The crankshaft, which has several interconnected and integrated parts, is a whole system unto itself. What is done during crankshaft repairs to get it running again?

To put it simply, crankshaft repairs are very complicated and cannot realistically be performed proficiently by just any business.

To perform complete crankshaft repairs, you not only need to disassemble the entire engine but also require some specialized tools.

As a result, you’ll also need trained professionals to complete this task because most mechanics lack competence with crankshaft reconditioning. Some may contend that replacing the engine is simpler (and probably less expensive) than fixing the crankshaft.

Here is an illustration of a process that occurs during crankshaft repairs:

Grinding

This is necessary to remove corrosion from or grind away at worn-out surfaces that may have been scraped.

Straightening

For crankshaft surfaces that have remained warped or bent as a result of metal-on-metal contact or prolonged exposure to heat.

Polishing

Cleaning the crankshaft of any impurities or debris and removing any small scratches or grooves is helpful.

Pulley

It functions as a link between the crankshaft and the serpentine belt, also known as the drive belt, which drives accessories like your air conditioner and stereo system and could want repair.

Bearings

As they experience the most stress, these are frequently the major crankshaft failure areas and could necessitate crankshaft repairs.

Cleaning

Numerous canals and tunnels on the crankshaft allow oil to effectively lubricate it, and they may be cleaned out during the repair.

Balancing

This refers to the crankshaft’s counterweight, which needs to be balanced again throughout the reconditioning process.

How Should Crankshaft Repairs Be Handled?

We decided to walk you through the process of making crankshaft repairs so you can have some fun (and learn). Again, this is a very complicated operation that calls for the proper equipment, expertise, and perseverance.

Even the most skilled do-it-yourselfers would frequently avoid this kind of task and hire specialists in its place.

Furthermore, it must be done correctly to avoid any catastrophe, later on, affecting your engine. The crankshaft tolerances are extremely tight in some cars, such as race cars.

The car engine cylinders by Kauczuk / CC BY-SA 3.0. The engine control unit cannot be provided with reliable information about the position of the piston by a crankshaft position sensor that is not working properly. The malfunctioning crankshaft position sensor may cause the engine to misfire inside the cylinder chambers.

Sometimes, the surface must be machined to a tolerance of 0.0003 inches from the manufacturer’s requirements. This could seem to be a hindrance, but you shouldn’t start looking for a substitute just yet.

If there’s a chance that your crankshaft can still be salvaged, don’t do it straight away and not while there’s still time. To determine whether any crankshaft repairs could be beneficial to you, you should undoubtedly consult with a technician to perform a thorough diagnosis.

Here is what the professionals at Ohio Crankshaft normally do to revive a battered crankshaft, assuming it can still be reconditioned.

1. The Examination

Before determining whether you need crankshaft repairs or complete replacements, it is advisable to do a comprehensive diagnosis as we have advised. Unfortunately, some crankshaft damage cannot be repaired.

If it can be saved, the staff at Ohio Crankshaft will thoroughly examine the extent of the damage. They are better able to comprehend what needs to be done to fix it as a result.

They placed the defective crankshaft through the “magnaflux” magnetic particle testing procedure. A ring of electrical current is thus induced all around the crankshaft in this situation.

It can therefore generate a magnetic field. A liquid solution containing finely ground iron powder that is magnetically attracted is added to the mix. Then, technicians examine the iron powder’s movement across the crankshaft.

The magnetic flow will be halted if the crankshaft has a crack because of the broken metal. The iron powder solution is then concentrated along the crack-affected areas.

This makes identifying areas of surface degradation much simpler. Additionally, professionals can use a UV light to illuminate the iron powder residue that would otherwise be difficult to see on the cracks.

2. Joining It By Welding

The crankshaft is moved to the welding station once technicians have determined that there are splits or cracks on its surface. But first, any foreign elements are removed by softly grinding and sanding the relevant crankshaft.

These impurities, which include tiny particles left over from worn bearings, can cake the surface.

Those minute pieces of debris can easily obstruct the path. The welders utilize something known as a “submerged arc” when they’re not around. They can efficiently penetrate any material build-up with the use of this equipment, which could facilitate machining afterward.

The entire area where the arc occurs here, distant from the high amperage of its welders, is covered by a gravity-led flux.

Additionally, this buried arc produces a gas that protects it from any airborne pollutants. Overall, this enables the professional operating the welding station to do more meticulous and exact welding. It makes sure that the crankshaft’s precise tolerances are met. Additionally, it ensures that later stations have it easier.

3. Straightening It Out

As a mechanic hands the crankshaft off to be straightened, we’re almost done. Here, the straightening station makes an additional check to make sure the crankshaft wasn’t affected by the previous welding and machining.

Car oil change by Aaberlanga / CC BY-SA 4.0. Whether it’s the bearings or the entire crankshaft, a regular oil change is more than enough to keep the crankshaft running smoothly. Because you don’t change your oil frequently, your crankshaft is failing or has failed much too soon in its lifespan.

It must continue to be straight and accurate in all dimensions. Additionally, the crankshaft’s radius along its ends must be precise.

The straightening procedure might be viewed as being pretty traditional for the most part. It all comes down to the experience of each specialist rather than relying on highly precise technology.

A hydraulic press is used to hold the crankshaft in place. There are many indicators on this machine that show the length and different parts of the crankshaft.

Once all calibrations have been completed, the technician gently applies pressure to bend the crank back to the correct specifications.

Again, their knowledge is essential in this situation because they can determine just how much counter-bending is required to keep the crankshaft inside tolerances. Any excessive re-calibration could permanently harm the crankshaft.

The crankshaft goes through heat treatment at the end of the process. This procedure is frequently carried out both before and after the crankshaft repair procedures described earlier.

Its exposure to different kinds and levels of heat is mostly dependent on the crankshaft’s fluctuation. Since overheating could seriously destroy the crankshaft, the technicians strictly adhere to the specifications suggested by the manufacturer.

How Much Would You Pay for Crankshaft Repairs?

We may now discuss a contentious subject: how much would crankshaft repairs set you back? Given how much work needs to be done to restore it in the first place, it is not cheap.

Additionally, there can be multiple components in need of repair at once. Additionally, to access the crankshaft, which is typically at the very bottom, you must disassemble the entire engine.

A crankshaft repair kit could fix the issue if the damage is minor and you’re eager to do it yourself. These kits, which cost about $400, include parts like gaskets and seals as well as bearings (both main and connecting rods).

These kits, however, are only useful if the parts around your crankshaft are at issue and the crankshaft has not already sustained significant damage.

The expenses of crankshaft repairs and replacements are generally very similar. As we mentioned before, the average cost of a comprehensive repair for a vehicle might range from $1,600 to $2,200.

A new crankshaft doesn’t cost a lot on its own. It might be purchased for between $400 and $800. However, labor costs would be the true bearer of the absurd expense.

It takes time to get to your crankshaft, and that’s before you think about mending or replacing it. It can take days of heavy labor to work on several cars, and the hourly labor alone will set you back at least $1,200.

By choosing remanufactured components rather than a brand-new crankshaft, you can reduce this cost somewhat. These may be purchased for as little as $200 and ought to be as sturdy.

Benefits of Carrying Out Crankshaft Repairs When Necessary

The crankshaft issue can be resolved without having to repair or replace the engine. For most autos, an engine replacement can cost between $3,000 and $4,000. For premium or larger vehicles, you should prepare to spend even twice as much.

The cost of a replacement will increase with the size of the vehicle and its engine. This means that replacing a crankshaft will be significantly less expensive for you financially than replacing an engine.

A dual-mass flywheel section by Cschirp / CC BY-SA 3.0. The crankshaft, which is joined by connecting rods, is found at the bottom of the engine where the pistons are housed. Once the pistons have started to convert into rotational motion, the crankshaft is subsequently connected to the flywheel.

Additionally, carrying out crankshaft repairs will guarantee your car’s continued dependability and safety. The more harm you do to your car the longer you drive it with a crankshaft issue.

How Can You Reduce the Cost of Crankshaft Repairs?

There are a few techniques to reduce the expense of crankshaft repairs or replacements, even though it is an expensive repairs.

To find out which technician in your neighborhood is offering the lowest price for a new crankshaft, make a note of their costs. You’ll discover that the cost of labor varies considerably between some of these locations.

You may also choose to go out and find the components you require for the required repair or replacement on your own. Be careful to ask a mechanic or the neighborhood auto shop what items you’ll need.

Purchase them yourself if you can do so for less money than the mechanic was going to charge you, and have the mechanic perform the labor on your behalf.

A mistake could result in substantially higher costs for crankshaft repairs in the long term due to the intricacy of the repair and the high cost of everything involved. Instead, you ought to take your vehicle to a reputable local technician who can replace it.

Are There Any Crankshaft Repairs You Could Skip?

Is it possible to go on now that I know how pricey crankshaft repairs (and replacements) are? To put it another way, could you continue operating a vehicle with a damaged or failing crankshaft?

Simply expressed, the response is a resounding NO. Repeated usage of a damaged crankshaft will only drive up repair costs further because it can seriously harm the remainder of the engine.

Also keep in mind that other factors, not the crankshaft itself, frequently contribute to crankshaft damage or failure. Most likely, there isn’t enough motor oil in the engine, which could be dangerous for other components.

Lack of oil can cause the valvetrain, pistons, rings, seals, and gaskets to wear out, among other things. Another approach to ignoring the oil shortage is to ignore crankshaft maintenance.

You can be putting yourself into the position of creating a catastrophic engine failure when coupled with a defective crankshaft. It costs money to rebuild a motor that has been seized.

On the other hand, replacing an old motor with a new one would likely set you back at least $3,000 in costs. Depending on the type of vehicle you drive, it might reach $10,000 or higher. Crankshaft repairs aren’t too bad in comparison.

The Conclusion

We have now finished discussing crankshaft repairs. All things considered, since the crankshaft is designed to survive as long as your car, you’ll probably never run across them.

However, if regular maintenance is not carried out, the crankshaft and most other components of your car will suffer. Even something as basic as not having enough motor oil is enough to wreak terrible damage.

No matter how indestructible it appears to be, crankshaft repairs or replacements are required once it is too late. Even the most enthusiastic hobbyists out there would find the repairs here difficult.

It could be very expensive as well as complicated. If your crankshaft (and engine) are seriously damaged, it might even be advantageous to sell or scrap your vehicle entirely, provided it isn’t overly valuable.

A car crankshaft by Alex Kovach / CC BY 2.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”