Your car’s engine begins to act strangely as you get in and turn it on, and it appears as though you won’t be able to leave your garage. However, once you start driving, everything seems fine and usual. The check engine light on your car is still on, though. What is occurring, then? Maybe this is a symptom of a bad IAC valve?

One way your car will let you know there is a problem you need to fix it if your idle starts to acquire a restless nagging. Frequently, but not always, idle problems are brought on by a broken or malfunctioning idle control valve.

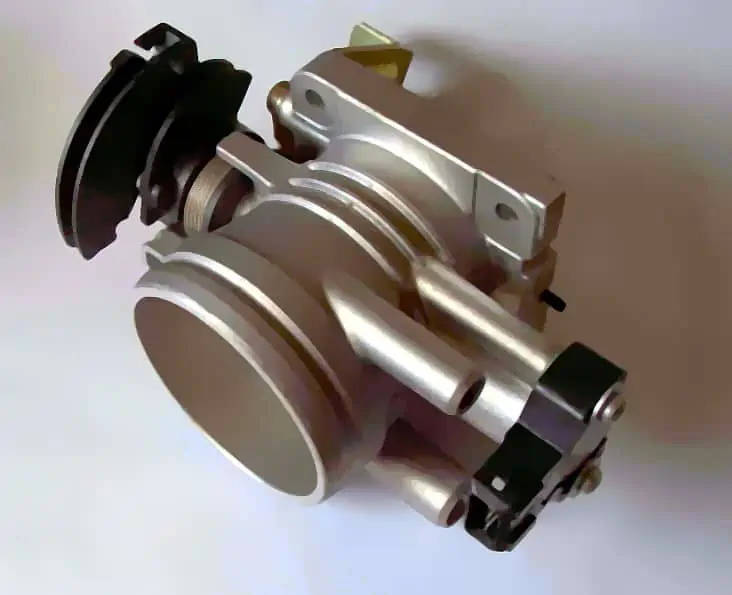

This little part, which may be found in your throttle body adjacent to your intake manifold, performs the function for which it was named. It’s a good thing for workshop greasers because it’s an easy item to reach, maintain, and replace.

The throttle body of the fuel-injected engine houses the vehicle’s idle air control valve. It controls the airflow to the engine in conjunction with the engine control unit or ECU.

By doing this, you may make sure that the automobile idles smoothly and does not stall when you come to a halt, such as at a stop sign. Up until the next time the car needs to be moved, it will continue to perform its mission.

However, there are some issues with this auto part. It may eventually stop working as a result of carbon buildups or damaged valve-related components.

Bad idle air control valve symptoms include unstable RPMs when the car is idling, an illuminated check engine light, sluggish engine idling, automobile stalling, and exhaust backfiring.

Due to the consequences of the component’s breakdown, a vehicle with a malfunctioning idle air control valve may pose a threat to the owner. Several idle air control valve symptoms raise concerns about a vehicle’s and its owner’s safety.

To avoid an impending accident, it would be advisable to keep an eye out for these indications and repair the problem right away. Additionally, replacing damaged auto parts before they fail will prevent you from having to spend extra money.

We’ve posted succinct but comprehensive instructions about your idle control valves and other crucial information related to them to help those who aren’t backyard mechanics. Learn more by reading on!

The idle air control valve for the car is housed in the throttle body of the fuel-injected engine. Together with the engine control unit, or ECU, it regulates the airflow to the engine.

An Idle Air Control(IAC) Valve: What Is It?

The IAC valve in a car is a part that is connected to the throttle and helps to control airflow so that the automobile idles smoothly.

When a car’s throttle plate closes while it is idling, the idle or transmission air control valve bypasses the plate to inject air, ensuring that the automobile idles smoothly and stops smoothly. The computer system sends a signal to the air control valve of the vehicle when it is stopped or parked.

The idle air control valve will change after the signal is received so that the required airflow rate is permitted inside the combustion area of the vehicle for smooth idling. Modern automobiles with computerized systems frequently exhibit this.

A car owner can identify certain indicators of a broken air control valve so that they can act quickly to fix the issue. Ignoring these warning flags could harm the car’s engine and put the driver’s life in danger.

What Purpose Does the Idle Air Control Valve Serve In a Car?

The idle air control valve is one of the major parts that the engine control unit, or ECU, regulates. By adjusting the quantity of air flowing around the closed throttle plate, it collaborates with the ECU to control the engine’s idle speed. Through a built-in conduit on the throttle body, it regulates the engine’s idle speed by bypassing air around the throttle plate.

When the engine is idle, the throttle is entirely closed. Only a small amount of air will be required to keep the engine running, and this air will be sent into the engine by the idle air control valve. This is possible because the idle air control valve contains a solenoid or valve-opening coil that opens and closes to regulate airflow.

The ECU regulates and chooses how much air is provided. Since it is electronically controlled, you can be sure that the required air volume can be maintained and will be changed when the engine load varies.

The valve is electrically operated if it is electronically controlled. The stepper motor type idle air control design is one illustration of this. A tapered pintle with 125 locations is used in this style of idle air control.

Starting at position zero, which corresponds to a fully extended position with the air bypass closed, it moves to position 125, which corresponds to a fully retracted pintle with the air bypass fully open.

The idle speed RPM increases when the position is raised. A higher air bypass causes an increase in idle speed for accessory loading, deceleration, or starting. Therefore, the idling speed will likewise be slower when there is less air movement.

By applying battery voltage to one of its two internal motor windings, the engine control unit may control the idle air control valve. Both of the aforementioned windings function by expanding and retracting the pintle, respectively.

Depending on the engine’s state or load, the ECU must actively manage the idle speed, constantly altering it to provide what the engine requires. For instance, the engine control unit responds to the air conditioner compressor turning on by opening the air bypass to prevent the RPM from falling.

An essential part of the car is the idle air control valve. It ensures a steady idle of the vehicle until it restarts from a halt. Even though this component is crucial, it was not made to stay forever. It might degrade with time. You can have some severe idle air control valve symptoms when this occurs.

The Engine Control Unit by Mgiardina09 / CC BY-SA 3.0. One of the important components that the engine control unit, or ECU, regulates is the idle air control valve. Together with the ECU, it regulates the amount of air flowing around the closed throttle plate to regulate the engine’s idle speed.

Which are the Most Common Issues with the Idle Air Control Valve?

Modern autos’ two most frequent problems which can result in bad idle air control valve symptoms include:

1. Blockage In the Idle Air Control Valve

Contaminants, dirt, and debris can enter the valve chamber during this exchange due to the volume of air going in and out of the idle air control valve. These impurities or contaminants may clog a valve, jam a system, or harm internal components.

2. Failure of the Idle Air Control Valve

The valve no longer getting an electrical signal or seals breaking out, resulting in the valve entirely failing and preventing the car from starting, are the second most frequent issues when resolving the idle air control valve symptoms.

What are Some Common Bad Idle Air Control Valve Symptoms In Cars?

If your car is having problems, you can tell if the IAC valve is broken by knowing the bad idle air control valve symptoms. Idle air control valve symptoms that are frequently bad include:

1. When the Vehicle Is Idling, the RPMs are Unstable

Unstable RPMs, while the car is idling, are one of the most typical faulty idle air control valve symptoms. It is a given that the car will not idle properly if the idle air control valve is malfunctioning. This issue may become apparent when your engine speed is varying when it is idle.

Additionally, you could hear the engine accelerating and decelerate between 100 and 200 RPM. Even if you did not touch any of the car’s controls, this may still occur for no apparent reason. When problems like this arise, they can be inconvenient because variable idle speeds might harm your engine’s performance.

It is advised that you have it checked and fixed as soon as you notice these typical idle air control valve symptoms.

2. There Is an Illuminated Check Engine Light

The check engine light illuminates to notify the driver when something is wrong with their vehicle. The check engine light might come on for several causes, but one of them is a broken idle air control valve.

This is because the idle air control valve has a significant impact on the car’s overall performance. When the car is idling, the ECU may detect abnormal RPMs and turn on the check engine light.

If your check engine light is on and you experience any of the bad idle air control valve symptoms, your IAC valve is probably malfunctioning.

3. The Vehicle Often Stalls

A malfunctioning idle air control valve may be one of the causes of a car stalling, particularly if it happens suddenly and for no apparent reason. The ECU’s inability to maintain engine speed and the failure of the idle air control valve are both potential causes of this.

The check engine light by Wikiuser100000 / CC BY-SA 3.0. When something is amiss with a driver’s vehicle, the check engine light will illuminate. A broken idle air control valve is one of the potential reasons for the check engine light.

The engine control unit must regulate and maintain the engine speed on its own if the idle air control valve malfunctions. It’s possible that the ECU can’t complete the task on its own.

The problem will progressively worsen when the ECU fails to keep the engine speed constant, enabling the RPMs to keep falling. When the RPMs drop too low, the engine will stall.

When the idle air control valve fails, the engine may not receive enough air when idling, which may cause it to stall. The combustion process won’t take place if the engine is having trouble getting adequate oxygen, which can cause the engine to stall.

4. Not a Smoothly Idling Engine

One of the most typical poor idle air control valve symptoms is an engine that is not idling smoothly. When the ECU is unable to regulate the engine speed because the damaged idle air control valve is throwing it off, the idling can become harsh.

A properly functioning idle air control valve ought to provide a smooth idle at all times. Even when you are just starting up or stopping at a red light, the idling should always be smooth.

When you experience rough and erratic vibrations, you will be able to identify if the engine is idling rough. Your car will start to tremble, and you’ll hear something strange in the engine noise.

5. The Exhaust System Often Backfires

One of the bad idle air control valve symptoms is when you hear a loud backfire coming from your car’s exhaust. It will sound like a loud bang, which is a typical indicator of some engine issues.

You will need to look for any further indicators, such as your car suddenly coming to a stop when you let off the gas, that can help you decide if the backfire is indeed brought on by a malfunctioning idle air control valve because it can be brought on by several different engine problems.

6. Uneven Idle Speed

Uneven idle speed is one of the most obvious and common symptoms connected to idle air control valve symptoms. The idle air control valve is intended to keep the idle speed constant while you are driving your car.

The engine idle speed may change unintentionally if the valve fails or has problems. This alteration in idle speed may cause an engine to idle that is extremely high or low, resulting in a surge and a loss in engine performance.

An irregular idle speed can fluctuate between being too high and too low at different times. Looking at the dashboard tachometer will help drivers spot changes in idle speed.

How Much Does Repairing a Bad Idle Control Valve Cost?

To prevent further issues from developing, you must get the idle air control valve checked and repaired right away if you suffer any of the faulty idle air control valve symptoms.

The damaged idle air control valve may need to be replaced, depending on the severity of the issue. Here’s what you need to know if you’re wondering how much it will cost to replace it.

Depending on the cost of the damaged parts and the labor rates of the shop you choose to fix them at, the replacement cost of the idle air control valve may vary. For older, more expensive automobile models, the idle air control valve can cost up to $400, but it can cost as little as $40 for ordinary car models.

The labor expenses can range from $50 to $70 per hour. Although it can be costly, replacing an idle air control valve should only take a few hours to complete. However, if the car requires extensive diagnostics, the price could still increase.

An automotive engine by CEFICEFI / CC BY-SA 4.0. An engine that is not idling smoothly is one of the most common signs of a defective idle air control valve. Idling might become severe when the damaged idle air control valve prevents the ECU from controlling the engine speed.

You will require it if you are unsure whether the issues or symptoms are brought on by a broken idle air control valve. Tests on other engine parts should be conducted to identify the issue.

IAC Valve Testing – How Is It Done?

When you have faulty idle air control valve symptoms, you could be concerned that you’ll have to pay for the necessary diagnostics and repairs. Thankfully, there are a few methods for identifying a broken idle air control valve.

Do-it-yourself diagnostics should only be performed if you are familiar with cars and are aware of the safety measures to take when working on them, so keep that in mind. You might need to utilize an OBD2 code reader or a digital multimeter, depending on the make and model of your automobile.

1. The ODB2 Code Reader Testing Method

To determine whether the ECU memory contains any issue codes, utilize an OBD2 code reader. You must turn the ignition key on and attach the code reader to accomplish this. Do not start the car. As soon as you are aware of the fault codes, be careful to clear them. After that, you can turn off the code reader and fire up the engine.

After starting the engine, if the check engine light is still on, turn it off and continue with the diagnostic. Drive your vehicle for at least five minutes even if the check engine light is not on. If it continues to be off, you may have an intermittent issue. Do some tests if it starts to come on.

2. Visual Assessments

To find the issue, perform some visual inspections. Examine the IAC wirings for any evidence of degradation, corrosion, burns, or damage. Look for any potential ground faults or open circuits brought on by shoddy insulation. The harness connector has to be examined as well.

When you unplug it, be sure the key is not in the ignition. Look for corrosion, crooked terminal pins, and loose connections. Check for carbon build-ups and make sure everything is clean because they can lead to defective IAC valves.

3. Performing Electrical Testing

With the engine off, you can turn on the ignition to check for the corresponding supply voltage. For information about your supply lines, consult your owner’s manual.

Turn the ignition on while the engine is off to conduct a ground test, then set the voltage test setting on your digital multimeter. One probe tip should be placed on the idle air control valve harness terminal that corresponds to the supply voltage, and the other probe tip should be placed on the terminal that represents the ground.

The voltage reading must match that from the initial test. You must examine the electrical resistance and ground line continuity from the control valve harness to the ECU if the reading discrepancy is larger than 10%.

4. The Idle Air Control Valve Cleaning

You can solve a problem with the idle air control valve by cleaning the idle air control valve. Cleaning the valve will assist get the debris off because carbon and certain other pollutants can accumulate within the car’s idle control during combustion.

A car engine by Tennen-Gas / CC BY-SA 3.0. If the valve malfunctions or breaks, the engine idle speed may change without your knowledge. This change in idle speed could result in an engine idling at a speed that is either very high or very low, causing a surge and a loss in engine performance.

To find out if using a carbon cleaner to remove built-up carbon from your car is safe, make an effort to search the owner’s manual for the vehicle. Tools like a wrench, coverall, flathead screwdriver, star screwdriver, and a fresh idle air control valve gasket will also be needed for the cleaning.

Once the tools are prepared, please consult the owner’s manual for the car and adhere to the instructions for cleaning the idle or transmission air control valve there.

However, using this general method, you may quickly clean the idle air control valve in your car.

Step 1: Locate Your Car’s Idle Air Control Valve

To start cleaning, find the idle or transmission air control valve. It is situated on the engine side, close to the air intake.

Step 2: Unplug the Electrical Connector from Behind the Idle Air Control Valve

Once you’ve found the idle air control valve for the vehicle, remove the plug from the back of it with a screwdriver.

Be careful not to damage the plastic tang holding the sensor’s wiring network in place. It protects the wiring harness from vibrations that could knock it away from the sensor.

Step 3: Remove the Screws or Nuts from the Idle Air Control Valve

The idle air control valve for the car should now be free of the bolts or screws securing it to the block.

Step 4: Spray the End While Holding the Downward-Facing Valve

Locate the valve that is facing downward and spray a carburetor cleaner over the pointed end of the valve after the bolts have been removed. Make sure to prevent the carburetor cleaner from entering the housing of the valve. Spray the component repeatedly until all of the carbon has been removed.

Step 5: Putting Back In Place the Wiring Harness and the Idle Air Control Valve

Put the idle air control valve back in place and fix the electrical harness once you are satisfied with the leaning. After that, start the automobile and assess how effectively it idles. Additionally, you can learn how to clean the idle air control valve without taking the part apart.

The Idle Air Control Valve Symptoms – How Can They Be Fixed?

Drivers may need to clean the idle air control valve if they experience idle air control valve symptoms, which include engine stalling, rough idle, the check engine light, and inconsistent idle speed. The accumulation of carbon deposits in the valve is one frequent issue that might result in the symptoms of a broken idle air control valve.

Cleaning the mechanism using these directions is the best way to fix the idle air control valve.

- Finding the idle air control valve is the first step. Fortunately, this process is simpler than you might think for new auto DIY owners. Between the intake manifold and the throttle body is where you’ll find the idle air control valve.

- To switch off the electrical components in the space where you will be operating, first, unplug the automobile battery. Failure to do so could lead to your electrocution or damage to other electrical components, raising the overall cost of replacement.

- Once the battery is disconnected, remove any other objects obstructing your access to the idle air control valve.

Car exhaust system by Alexander Migl / CC BY-SA 4.0. When you hear a loud backfire coming from your car’s exhaust, that is one of the bad idle air control valve symptoms. It will make a loud bang sound, which is a common sign of various engine problems.

- The air intake ductwork should be disconnected from the throttle body. The throttle body is situated between the air intake and the manifold, as is common knowledge.

- Remove the electrical sensor from the idle air control valve’s backside. The majority of the time, you can remove these connectors by hand, but if they get stuck or jammed in the palace, you might need a tool.

- Start the engine of your car. Maintain a constant idle speed between 1,000 and 1,500 RPM on the tachometer as you gradually increase it.

- Spray the engine cleaner or throttle body cleaner into the throttle body’s main compartment. Find the idle air bypass port if you haven’t done it already, then spray the majority of the cleaner into this space.

- To prevent the cleaner from heating up too much, turn off the engine and let it soak into the tube.

- Allow the cleaner to work for three to five minutes.

- Restart the engine of your car. Hold the RPMs between 1,000 and 1,500 when revving the engine.

- Replicate the complete cleaning procedure now (steps 1-6 in order).

- Reconnect the air intake duct to the throttle body after shutting off the engine.

- Start the engine of your car, then raise the idle speed to 1,500–2,000 RPM. Drivers must pay attention to any white smoke emerging from the exhaust pipe during this stage. The car should be revved until no more white smoke is coming from it.

- Last but not least, one of the most typical idle air control possible signs is an increase in idle speed. In this situation, you must repair this component before operating your vehicle.

Can You Drive with an Idle Air Control Valve That Is Faulty?

Depending on the circumstances and the model of the vehicle, it is occasionally possible to operate a vehicle with a broken idle air control valve. Other times, driving when an idle air control valve is malfunctioning might cause more idle air control valve symptoms, increasing engine damage and impairing performance. Drivers shouldn’t operate a control valve that is broken because of the risk involved.

Although some motorists may believe that keeping their car from idling will solve the issue, every time you stop at a stop sign, roundabout, red light, or other traffic halts, your car may idle. You will encounter idle air control valve symptoms in this situation.

The Conclusion

If you correctly maintain your vehicle and take it to an auto service shop at least once a year for a comprehensive diagnostic and maintenance, you can prevent bad idle air control valve symptoms and issues. This will keep your vehicle in good working order before its components wear out.

By purchasing and using products to clean your IAC and throttle components, you can also increase the lifespan of your idle air control valve. However, you must exercise caution when performing DIY cleaning and repairs.

Nothing is more annoying than feeling as though your automobile has been running at a high level and then having the check engine light come on in your dashboard. You worry about the strength, longevity, and performance of your car because it seems like nothing can go right with your car.

Fortunately, compared to other engine parts, the idle air control valve is quite inexpensive to replace and repair. By avoiding the expensive labor expenses by performing this task on your own, you may eliminate the idle air control valve symptoms and keep repair costs at an all-time low.

The check engine light by Wikiuser100000 / CC BY-SA 3.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”