The primary purpose of pushrods in overhead valve engines is to deliver the reciprocating motion necessary for the internal combustion engine to operate at its best.

Pushrods are typically moved by a cam to open and close an internal combustion engine. In this article, we’ll go over the signs of a bent pushrod.

You’re more prone to experience bent pushrod problems than not if your car has an overhead-valve engine. Because of this, this article frequently describes the causes and effects of bent pushrods.

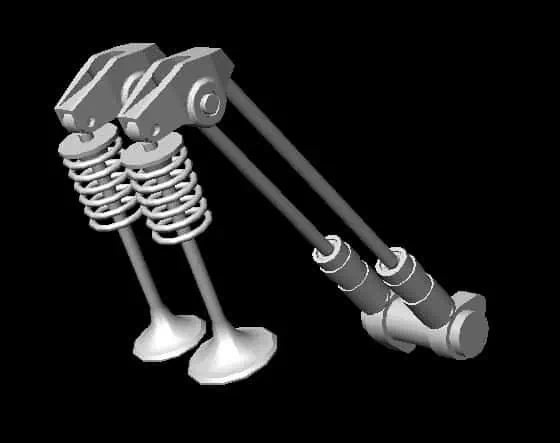

An overhead valve engine’s pushrod is a cylindrical rod that a camshaft uses to open and close valves. Pushrods feature apertures on both ends that aid in supplying and receiving oil to the rocker’s arms.

Another element that is crucial to internal combustion engines is the rocker’s arm. Pushrods and rocker arms function together seamlessly.

A Pushrod: What Is It?

A component of the valvetrain that goes up and down perpendicular to the crankshaft’s rotation is referred to as a pushrod in common parlance.

Pushrods and rocker arms work together to activate the valves, which are normally found in the cylinder head, in an overhead valve engine. Conversely, pushrods are substituted with one or more camshafts, sometimes referred to as “buckets,” in overhead cam engines.

What Do Pushrods Do In a Car?

A camshaft in an engine converts rotational motion into linear motion, which the valves use to open and close to permit fuel and air into the combustion chamber.

Components of a traditional OHV engine valvetrain by IJB TA / CC BY-SA 3.0. Rocker’s arms are used in OHC engines instead of pushrods, which is the distinction between OHV pushrod systems and OHC engines.

One or more camshafts and pushrods operate in concert to move the rocker arms, which pivot and actuate valve stems, to accomplish this.

There are two such systems, one for opening the valves and the other for closing them, on each cylinder. These are controlled by camshaft lobes, which at specific points throughout each engine cycle convert this circular motion into up-and-down or back-and-forth movement.

“Up” in most engines refers to the direction of the valves, which are found at the top of the cylinder head.

An intricate camshaft position sensor mechanism is employed in some older systems. To determine each lobe’s precise role throughout each engine cycle, this system must account for the variable height of each lobe.

The majority of engines built from the early 20th century to the present day have overhead valve (or OHV) engine designs, in which one or more camshafts and pushrods control the valves.

Together, these parts move the valves up and down in sync with the rocker’s arms so that air and fuel enter the combustion chamber at precisely timed intervals.

Pushrod Engines: How Do They Work?

Its valves are not operated by overhead valves (OHV), but rather by one or more camshafts and pushrods.

Despite having rocker arms that open and close valves in common with their OHV counterparts, pushrod engines are typically less complex since they don’t have many of the auxiliary elements found in OHVs, such as the rocker bridge, distributor, oil pump, etc.

In comparison to OHV engines, they are also able to achieve higher compression ratios thanks to the extra space between the top of the combustion chamber and the cylinder head.

An internal combustion engine with overhead valves has its valves located in the cylinder head. Compared to the previous flathead engine’s location of the valves near the piston in the block, this was an improvement.

The difference between OHV pushrod systems and overhead camshaft (OHC) engines is the employment of rocker’s arms as opposed to pushrods. The location of the camshaft(s) above or next to (rather than inside) the cylinder head is referred to as being “overhead” (s).

A pushrod is vulnerable to damage from accidents or wear and tear from increasing mileage. This may result in another mechanical issue in the valvetrain, such as a loose rocker arm or a damaged lifter (lifters are part of the oiling system).

Bent pushrods need to be replaced right away since they could harm other parts and perhaps let combustion gases into the cooling system, which can cause overheating.

What Causes the Bent Pushrod Symptoms to Appear In a Car?

This can happen for some reasons, such as wear and tear from frequent use or damage from an accident.

In this instance, a mechanical issue with the valvetrain, such as a loose rocker arm or a damaged lifter, is probably to blame (lifters are part of the oiling system).

Using pushrods, the valves in an overhead valve engine convert rotational motion into linear motion as they open and close to let fuel and air into the combustion chamber. “Up” in most engines refers to the direction of the valves, which are at the top of the cylinder head.

Pushrod engines often feature fewer auxiliary components than OHV engines, such as the rocker bridge, distributor, oil pump, etc., despite sharing rocker arms that open and close valves with their OHV counterparts.

One or more camshafts and pushrods work in concert with the rocker’s arms to pivot and operate the valve stem to accomplish this. An intricate camshaft position sensor mechanism is employed in some older systems.

To determine each lobe’s precise role during each engine cycle, this must take into consideration the variable height of each lobe.

How Can You Know When a Pushrod Needs to Be Replaced?

Pushrods in overhead valve engines are vulnerable to damage from accidents or accelerated wear and tear with increased mileage. This may result in another mechanical issue in the valvetrain, such as a loose rocker arm or a damaged lifter (lifters are part of the oiling system).

Bent pushrods need to be replaced right away since they could harm other parts and perhaps let combustion gases into the cooling system, which can cause overheating.

The system for lubricating lifters, commonly referred to as tappets, is found in engines. Lack of lubrication might cause other valvetrain parts (such as pushrods) to wear out early when they wear out or fail.

During engine running, tapping noises originating from the top end is frequently used as proof of this. Other signs may include jerky acceleration and harsh idling; if this is the case, it’s time to have your car serviced.

How Much Does It Cost to Fix Bent Pushrod Symptoms?

Your car’s pushrod will need to be replaced if it is bent. Depending on the make and model of your car as well as the extent of the damage, the price of this replacement will change.

One of the trickiest maintenance jobs on an internal combustion engine is swapping out a faulty pushrod. Since it includes disassembling and reassembling some of the most important parts of your car’s engine, this replacement task is highly difficult.

A bent pushrod replacement typically costs between $800 and $1,200. If extensive damage necessitates additional parts or repairs, this repair may even be more expensive.

Between $350 and $550 can be spent on a complete push rod replacement kit that contains all necessary parts, including guide plates, rocker arms, pins, valve cover gaskets, and seals. If the current valve cover is harmed, you might also need to get a new one.

It takes a professional mechanic six to eight hours to replace a bent pushrod. Therefore, the price of labor will range from $480 to $960. Only a skilled mechanic should try to complete this challenging repair.

The right tools and equipment for the job are also crucial. It’s crucial to thoroughly read all instructions and take your time if you try to fix this yourself. Your engine could sustain serious damage if you make a mistake.

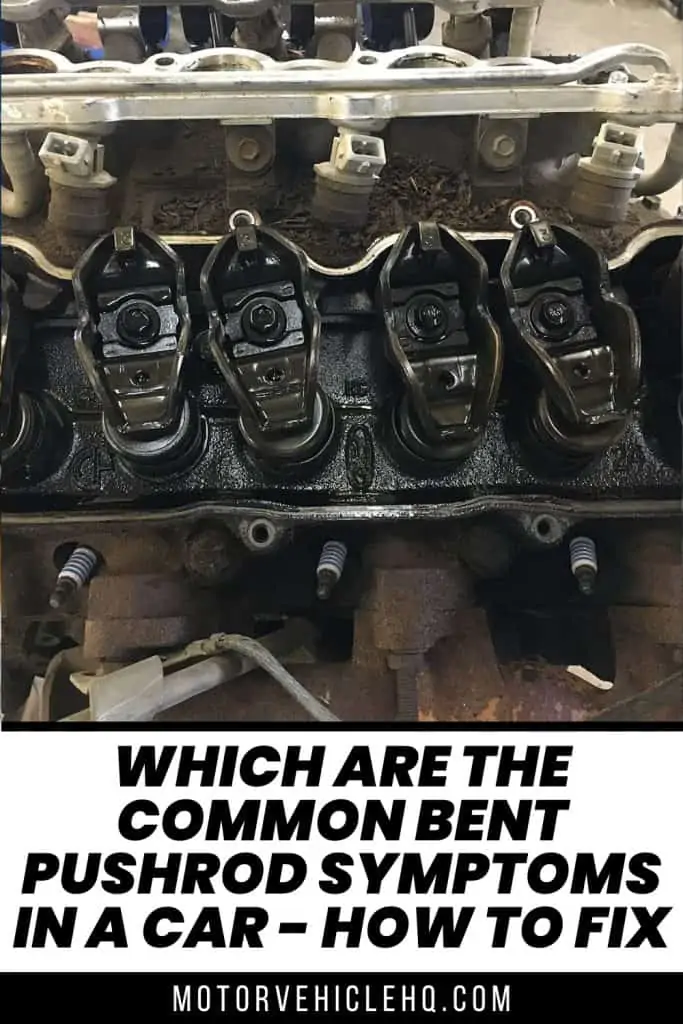

Which are the Common Bent Pushrod Symptoms In a Car?

Although the signs of a bent pushrod may not be immediately apparent, if you know what to look for, you shouldn’t have any trouble diagnosing one.

Numerous signs lead to a bent pushrod. The majority of these symptoms, though, can also be brought on by other engine system malfunctions. You should be able to identify a bad or bent pushrod in this regard.

Faulty hydraulic lifters and bad rocker arms will produce the same noise as a bent pushrod.

An example of a push-rod suspension setup by Andy Dingley / CC BY-SA 1.0. Replace bent pushrods immediately since they could damage other components and perhaps allow combustion fumes into the cooling system, which can lead to overheating.

1. Misfiring Engine

One of the most typical signs of a bent pushrod is an engine misfire. There are numerous potential causes for the misfire, but the pushrod improperly opening the valve is the most likely one. This may result in the air/fuel mixture entering the cylinder at the incorrect time, leading to an engine misfire.

You will have poor cylinder performance if your pushrod is bent. Let’s say you discover that one or more of your cylinders are not performing as they should.

A misfiring cylinder suggests that your fuel injectors, spark plug coil, or ignition system may be malfunctioning. Another potential culprit is a bent pushrod. You can perform a visual inspection if you think your pushrod might be damaged.

A malfunctioning spark plug, ignition system, or fuel injector are some additional potential causes of an engine misfire. The pushrod is probably to blame, though, if you have ruled out all of these other possibilities.

2. Internal Engine Ticking Noises

A bent pushrod might also make the engine make a ticking noise. Pushrod noise is typically caused by either a broken pushrod or worn-out rocker arms. The engine may operate unevenly and generate a knocking noise if the pushrod itself is bent.

Alternatively, if the rocker’s arms are worn out, they could not be able to operate the valves effectively, which would cause noise in the valvetrain. In either scenario, it’s crucial to have a skilled mechanic examine your engine to find the source of the noise.

While accelerating or idling, your car’s engine may knock or make a ticking noise for a variety of reasons. Your engine will bang if there are any stiff hydraulic lifters, worn-out rocker arms, bent coin rods, damaged pistons, or failing, or defective oil pumps.

What noise does a bent pushrod make, you might wonder. Ticking can also be caused by a bent pushrod, but before it reaches this point, your pushrod is long gone.

3. A Rough Idle

Rough idle is another sign of a bent pushrod. This can result in the engine running poorly because the pushrod is not properly opening and closing the valves. If the pushrod is bent, the engine may potentially stall or have trouble starting.

4. Higher Emissions

Additionally, bent pushrods can increase engine emissions. This is due to improper combustion of the air/fuel mixture, which causes unburned fuel to be released through the exhaust system. A bent pushrod probably is to blame if you discover that your car emits more pollutants than usual.

5. Poor Acceleration and Engine Performance

A bent pushrod can also cause a vehicle to perform poorly and accelerate slowly. This is because the engine’s inability to properly breathe can cause power to be lost. When you try to accelerate, the engine can also lag or stall.

Due to its inability to deliver the proper amount of force from the cam to the valve, a bent pushrod results in poor performance and acceleration. As a result, valves may not fully open, fully close, or close at the appropriate moment.

As a result, engine performance and output may be impacted if the air/fuel mixture enters or leaves the combustion chamber at an improper moment.

The car pushrods by 4wheel fan / CC BY-SA 3.0. One of the most prevalent causes of poor engine compression is bent pushrods. When pushrods are bent, they lose their ability to efficiently transfer the force from the camshaft to the valves.

6. Reduced Compression Test

The blending of air and fuel in the engine cylinders is referred to as engine compression. This procedure is necessary for the efficient operation of your engine.

You may have problems like a misfire when starting your engine, jerky idling, or subpar performance while idling or operating your cab if there are any problems along this route.

Pushrods aid in the opening and closing of the valves, as was previously mentioned. The pushrod won’t be able to slide up and down smoothly if it bends, which will slow down the valve’s opening and shutting.

Pushrods that are bent are among the most frequent reasons for low engine compression. Pushrods can no longer effectively transmit the force from the camshaft to the valves when they are bent.

Due to this, the valves may not fully open, reducing the amount of fuel and air that can enter the combustion chamber. The engine’s compression ratio is dropped as a result, and it might not be able to produce enough power to function as it should.

A bent pushrod may be to blame if your engine is producing low compression on one or more cylinders. To check for this problem, you can run a compression test. Low readings on one side of the engine suggest that a bent pushrod is the root of the issue.

NOTE: Your engine’s low compression test could be brought on by a variety of other circumstances. A low compression condition could affect one or more cylinders.

To visually check if your pushrods are bent, you must know how to inspect them.

You will need a good mechanic’s toolbox on hand to perform a visual inspection. If your throttle cable is preventing you from moving, open your bonnet and unhook it. Remove any obstructions such as wires in your path.

The fittings holding your valve cover should be unbolted. Play the pushrod while holding it between your fingers; it should play freely but not too loosely.

Take your wrench socket and unbolt the bolt holding it with the rocker’s arm if it’s difficult to play or appears to have numerous gaps. You are not required to remove it. The arms of the rocker can be moved.

It’s possible that playing it or simply glancing at it won’t reveal every bent pushrod. Roll the pushrod on a flat piece of plywood or, better yet, a piece of glass to quickly identify any bent pushrods. You’ll see it. The twisted pushrod will not roll freely on the glass.

What Causes Bent Pushrod Symptoms In a Car?

Pushrods that have been bent can be the result of an accident or ordinary wear and tear over time, just like many other types of vehicle damage.

Rough terrain and on-road trash might make it more likely that your engine will malfunction mechanically since they put more strain on its parts.

This implies that if you frequently drive through hazardous situations or construction zones, you may wish to have a rocker guard fitted to provide an additional defense against harm like this.

Pushrods that are bent may also be the result of poor installation or a defective component. It’s crucial to get your car assessed and fixed right away if you notice any of the aforementioned symptoms.

The car engine by Kether83 / CC BY 2.5. Engine compression is the process of mixing gasoline and air in an engine’s cylinders. The effective operation of your engine depends on this technique.

1. Normal Wear and Tear

Several variables, including wear and strain, can result in pushrods in an engine system bending. The metal parts merely rubbing against each other over time, generating heat and friction, is the most frequent reason. This may eventually cause the metal to deform or even break.

Additionally, regular engine cycling (starting and stopping) can strain the pushrods, which over time may result in bending. Pushrod bending can also be caused by improper installation or engine care (such as infrequent oil changes).

2. Unsecured Valve Guides

One or more potential causes of bent pushrods in an overhead valve engine include loose valve guides or broken valve springs. The valves may move more freely than they should if the valve guides are unfastened. This may disrupt the rocker’s arm motion and cause the valves to move irregularly.

Since the pushrods and rockers’ arms are joined directly, any irregularity in the rockers’ motion might cause the pushrods to bend. Pushrods’ length as hollow metal tubes should be taken into account as well because even a small force applied across their longitudinal axis might cause them to bend.

3. Overheated Engine

Pushrods in overhead valve engines may bend due to overheating’s effect on the metal’s expansion. This may result in the pushrods going out of alignment, which may result in the engine misfiring or knocking. This can eventually harm the engine if ignored.

Maintaining a full tank of engine coolant and never letting the engine become too hot will help you avoid this. If you suspect that your engine is beginning to overheat, stop immediately and turn it off.

4. Hydraulic Lifters That Stick

Sticking hydraulic lifters is another factor that could lead to bent pushrods. Some engines employ hydraulic lifters to operate the valves. They function by modifying the space between the valve and the rocker arm by use of oil pressure.

However, if they get trapped, they might exert too much pressure on the valves, which might bend the pushrods. Additionally, broken valves and misfired engines might result from this.

5. Unstable Rocker Arm

As is common knowledge, the pushrods in an overhead valve engine are in charge of transmitting the camshaft’s motion to the valves. The valves are opened and closed by a lever created by the rocker arms, which are positioned on top of the pushrods.

A rocker’s arm may start to bounce up and down on the pushrod if it becomes loose. The pushrod may eventually bend as a result of this continuous action. Poor engine performance results from the pushrod being bent since it can no longer effectively transmit the camshaft’s motion to the valves.

6. Unintentional Damage

Another potential explanation for bent pushrods is accidental damage. This may occur if the engine is dropped or struck so forcefully that the pushrods bend.

Another scenario is when a foreign object, such as a piece of trash, enters the engine and strikes the pushrods. It is preferable to take your engine to a mechanic for inspection if you suspect that it has been damaged.

7. A Bad Installation

One of the most prevalent reasons for bent pushrods is improper installation. One way is by not tightening the rocker’s arms down enough. The pushrods may be subjected to excessive force and flex if the rocker’s arms are not correctly torqued down.

6 stamped steel rocker arms by Redelback49 / CC BY-SA 4.0. An overhead valve engine’s pushrods are responsible for transferring the camshaft’s motion to the valves. The rocker arms, which are positioned on top of the pushrods, act as a lever to open and close the valves.

Using pushrods that are simply too weak for the application is another frequent reason. It’s crucial to use pushrods that are adequate for the job because weaker materials are more likely to bow under heavy loads and pressures.

How Can Bent Pushrod Symptoms Be Fixed?

The most popular remedy is to replace the bent pushrod if your car exhibits any of these symptoms. There are numerous ways to accomplish this, but typically the cylinder head must be removed.

Depending on the method you select, costs will change, therefore it’s critical to speak with your mechanic to receive a precise estimate.

For those who wish to perform the repairs themselves, there are also aftermarket replacement components available; however, they frequently have a higher price tag than OEM parts from the car manufacturer.

It’s recommended to have your vehicle serviced by a competent mechanic if you don’t feel confident handling this type of repair yourself or don’t have access to the required tools and equipment. They’ll be able to identify the issue and solve it quickly and affordably.

Most of the time, routine maintenance is an efficient technique to stop bent pushrods. However, the risk of harm to your vehicle’s parts may increase if you’re traveling on unpaved roads or through regions where there is a lot of litter on the ground (such as construction zones).

To reduce the chance of rocker arm damage, many individuals decide to install rocker guards, which are simple DIY tasks.

Can a Bent Pushrod Be Straightened?

A pushrod can be straightened, but doing so calls for the use of specialist equipment and an understanding of how it functions. If you choose, you might be able to locate instructions for this task online.

However, every step must be carried out precisely to avoid damaging any further parts in addition to your pushrods.

Before making any repairs by hand or using basic household tools like hammers or pliers, it’s usually best left up to professionals who have experience working on cars.

How Often Should My Pushrod Be Replaced?

The lifespan of a pushrod will vary based on how frequently it is used and the operating environment, so there is no universal solution to this problem.

However, the majority of mechanics advise swapping these out every time you get your engine oil changed, which is normally every 5000 miles. This is a smart preventative practice that will keep your car in good shape for many years to come.

Is It Safe to Drive with Bent Pushrod Symptoms?

While it is possible to drive with a bent pushrod, it is not advised. Left unattended, bent pushrods can harm your engine more and eventually cause far more serious issues. It’s essential to get any signs of a bent pushrod examined as soon as you become aware of them.

Take your car to a qualified technician for additional diagnostic and repair if you don’t feel confident handling this yourself or if you don’t have access to the required tools and equipment.

Pouring fresh motor oil into an engine by Aaberlanga / CC BY-SA 4.0. The oil lubricates the engine and prevents its components from contacting one another. Friction can eventually cause a pushrod to bend if it isn’t greased.

How Can a Pushrod Be Prevented from Bending?

A push rod can be kept from bending in many different ways. These consist of:

1. Regular Engine Oil Changes

One of the most crucial techniques to stop push rod bending is this. The oil keeps the engine’s parts from coming into contact with one another and lubricates it. If not lubricated, friction may eventually lead to pushrod bending.

2. Using Pushrods of Higher Quality

Pushrods come in a wide variety of styles today. Some are built with better materials that are less prone to warp or shatter when put under pressure. It’s crucial to select a push rod that is appropriate for your application.

3. Engine Vibration Reduction

Engine vibration is one of the main reasons for pushrod bending. Installing engine mounts, utilizing balancing weights, and adding dampening material to the engine bay are just a few methods for reducing engine vibration.

4. Observing the Proper Installation Guidelines

When installing push rods, it’s critical to follow the right installation techniques. The push rods are susceptible to breakage or bending if they are not placed properly.

5. Preventing the Pushrod from Being Overly Stressed

It’s crucial to keep the pushrod from being overextended. Avoiding abrupt starts and pauses as well as overloading the engine will help you achieve this.

The Conclusion

Pushrods that are bent are relatively uncommon, and they may be fixed with the proper equipment and training. If you notice any of these signs, get in touch with your mechanic for advice on how to quickly identify and fix the issue.

Your engine may experience a variety of issues if your pushrod is bent. We will talk about bent pushrod causes and solutions in this article.

Pushrods rarely bend, however driving on muddy roads or using the engine heavily can harm them. The most frequent solution is a replacement, which needs to be carried out by a specialist.

The signs of a bent pushrod have been extensively discussed. It’s critical to understand that there are things you can do to stop your engine from making stuck noises. As we all know, a worn-out valve or bent pushrod is the cause of these ticking noises.

The number of studs and sludge in your engine can be decreased with routine oil changes using the proper oil grade for your engine. Pushrods will slide smoothly if your engine is sludge-free.

6 stamped steel rocker arms by Redelback49 / CC BY-SA 4.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”