Internal combustion engines that are getting older are more susceptible to a variety of potential problems. While some of these faults are relatively small in scale, others can cause serious drivability problems, which frequently call for an expensive repair. Of course, nothing about this is ever ideal.

Few of these more serious problems are as hated as a burst head gasket. One of the most troublesome problems for drivers whose motors have started to age is a burst head gasket. Unfortunately, head gasket repairs are rarely quick or inexpensive. This fact alone is a frequent cause of worry for people dealing with such problems.

Although blown head gaskets are not very frequent, they do happen frequently enough to highlight the need to understand the signs of such a situation. These signs may be swiftly identified so that a repair can be started and your car is back on the road as soon as possible.

Continue reading to find out more about the function of an engine’s head gasket and the different signs and symptoms that point to a blown head gasket.

A Head Gasket: What Is It?

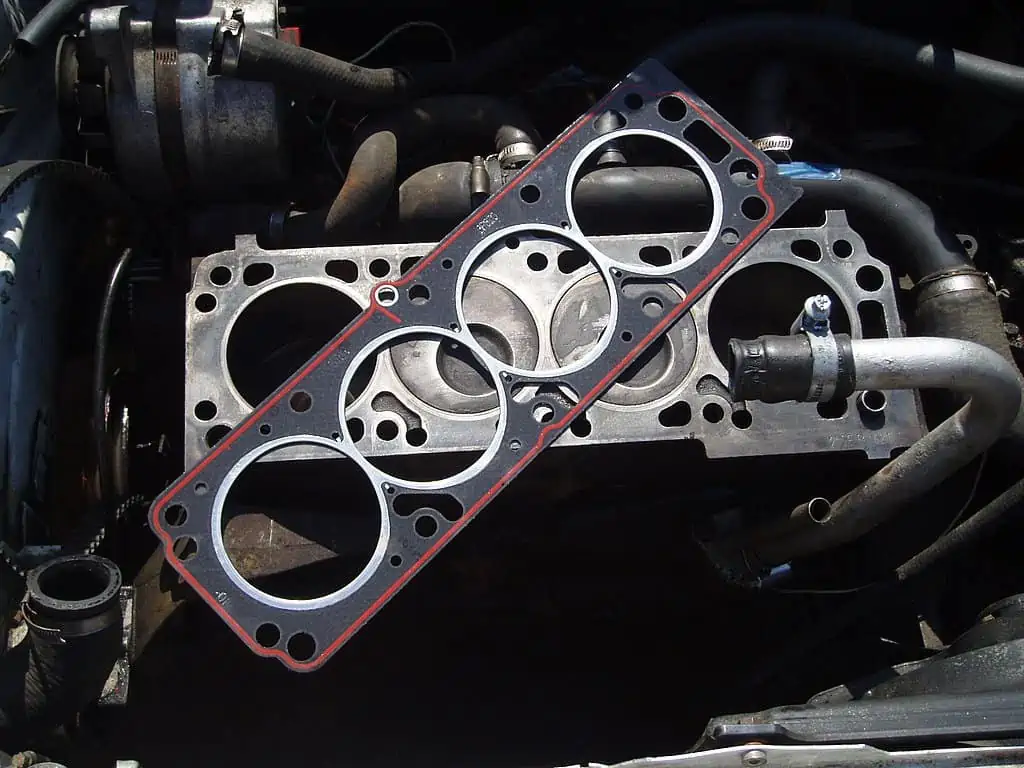

The unique seal between the cylinder head and engine block in an internal combustion engine is called a head gasket (s). This seal stops coolant and oil from entering an engine’s combustion chambers as well as the escape of combustion fumes from the cylinders.

Head gasket by Collard / CC BY-SA 3.0. This is a specific seal that an internal combustion engine uses between the cylinder head and the engine block.

Depending on the precise configuration of an engine’s cylinders, each engine has 1-2 head gaskets. One head gasket is present in an inline engine since there is only one cylinder head. On the other hand, “V” layout engines have two separate cylinder heads, and as a result, two head gaskets.

Production engines used often use copper head gaskets and a variety of composite gaskets, which were generally made of graphite or asbestos. Today, Multi-Layer Steel (MLS) head gaskets make up the majority of manufacturing head gaskets. These gaskets consist of two to five layers of thin steel, often covered in a rubberized covering.

The head gasket(s) of an engine is secured in place between the engine block and heads using carefully torqued head bolts. These bolts frequently have a torque-to-yield design, which stretches as they are tightened to create the best clamping seal.

The head bolts on an engine are also torqued in a certain way, which frequently entails starting with the centermost bolts on each head and moving outward.

What Is the Function of a Head Gasket In a Car?

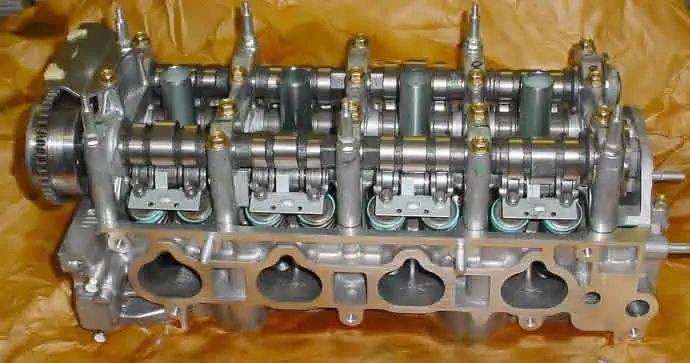

The pistons and cylinders of your car’s engine are housed in the cylinder block, while the valves, spark plugs, and camshafts are all found in the cylinder head. The head gasket sits in cushioning between these two substantial engine components.

The head gasket, one of the most important gaskets in your engine, is made to keep coolant and engine oil from leaking into the cylinders as well as to the outside. It also serves to seal the cylinders’ firing pressure. In addition to keeping out cylinder pressure, coolant, and engine oil flowing via casting ports, the head gasket must endure pressures caused by the two surfaces expanding, contracting, warping, and rubbing together.

What Would It Mean When a Head Gasket “Blows”?

When a head gasket’s structural integrity has been jeopardized, it is referred to as having a “blown head gasket.” The block deck and cylinder heads of an engine cannot be properly sealed together because of this defective head gasket section. This causes a leak, which might show up in several ways.

A head gasket’s specific point of failure might result in a variety of problems, depending on the situation. Coolant or oil can be forced internally or externally into one or more cylinders of an engine. Additionally, the displacement of oil and coolant into one another might cause fluid mixing.

Additionally, combustion gases may leak from a failing head gasket and end up in the crankcase or the cooling system of an engine. Alternatively, a burst head gasket might cause the combustion gases from one cylinder to leak outside the engine or into another cylinder nearby.

Any form of head gasket leak can cause several drivability-related problems, which might get worse as the leak’s severity increases. Overheating and compression loss are two of the most dangerous side effects of a ruptured head gasket.

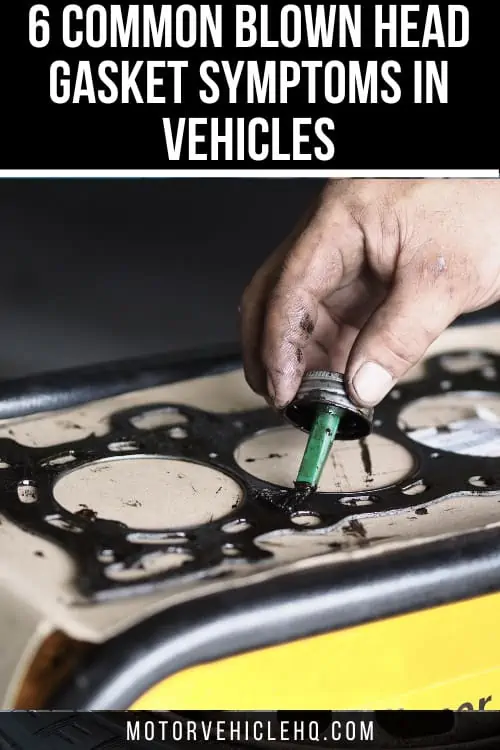

What are the Symptoms of a Blown Head Gasket?

A blown head gasket exhibits signs that are difficult to ignore. When compression is lost, the power loss and faulty combustion can cause the car to operate extremely badly. Here are the six warning indications you would look for if you thought your head gasket has blown.

A damaged head gasket by Collard / CC BY-SA 3.0 This will eventually result in more overheating problems. Severe failure result in coolant loss, either exterior leaking or escape inside a particular cylinder.

1. Coolant that Bubbles

Pressurized air in the radiator is one of the more obvious symptoms you may detect when diagnosing a gasket leak since the head gasket is intended to seal the combustion processes. Air will pass through the radiator and create bubbles in the coolant if the engine is losing combustion pressure to the cooling system.

The coolant may appear to be boiling as a result of combustion gas leaks if there is continuous airflow from the bottom. You might also decide to do a rev test to check concerns about compression leakage. Have squeezed the gas pedal while watching to see whether the container with bubbling coolants leaks.

And if it does, your head gasket is probably blown. In this situation, a head gasket leak is already pretty advanced, and you need to repair it right away to limit future damage.

2. A Lot of White Smoke From the Exhaust

Moving to the back of the car, you can see clear white smoke rising from the exhaust pipe, which is another very typical indication.

This also happens after the issue has progressed past the initial warning indications, as white smoke can only be brought on by fluids, notably coolant that is seeping into the combustion chamber.

However, you shouldn’t mix this with the morning’s little puff of white smoke. Condensation may cause a little amount of smoke, but if coolant is burning in the combustion chamber, you may notice an excessive amount of white smoke coming from your exhaust.

You may confirm this by having someone rev the engine as you inspect the tailpipe because this may be more obvious while pushing the accelerator pedal.

3. Loss of Coolant With No Visible Leaks

Here’s where you might be able to identify the issue a little earlier and get the car professionally inspected before any significant harm is done.

Fluids may seep into the combustion chamber through a head gasket internal leak and burn as they exit the engine. Therefore, you would see that your antifreeze was going without a trace since the coolant would continually be burned up in combustion.

Naturally, this will cause the engine’s temperature to rise, therefore you should always check your coolant levels when this happens.

You could have an internal leak if your coolant levels seem to be on the lower side without any obvious leaks. To further prove it’s a head gasket leak, you might also return to the scene and check the color of the smoke.

Even if your check engine light may come on sooner than you think for a coolant replacement, some automobiles with coolant gauges can be useful in such a situation.

This type of issue can also arise if the radiator is not cooling the coolant, in which case the antifreeze leaves the engine via burning while it is circulated rather than by burning directly.

Therefore, be careful to inspect the radiator as well.

4. Misfiring Engines and a Dark-Colored Coolant

Contamination with ignition residuals is one of the indicators that distinguish a typical coolant leak from other probable sources. Not only will the reservoir be bubbling with air as a result of the combustion gases escaping upward, but you might not detect changes in the coolant’s color.

Gasket containing chrysotile asbestos by Jonas Börje Lundin / CC BY-SA 4.0. Because of its characteristics, asbestos was a helpful material in creating gaskets. A heat-resistant, nonconductive, and noncorrosive chemical, asbestos. This helps to minimize cases of head gaskets blowing off due to heat accumulation or corrosion.

The coolant reservoir becomes a foul-smelling, frothy black liquid as a result of the engine’s frequent misfires and leaks of combustion gasses. Dark coolant and bubbling may be an obvious sign of a ruptured head gasket.

5. Contamination of Fluids

A complete jumble of vehicle fluids is another symptom that can indicate a probably blown head gasket. A head gasket is crucial for ensuring that all of the fluids in your car follow their intended paths and remain contained in the system. Your car contains many different fluids, each of which has its passageway.

There are several holes in the head gasket’s sheet that are intended for fluid passage. Any one of those cracks might cause the engine to experience a cascade of issues. You’ll note that certain fluids have been mingled in with the others and that others have not been adequately controlled.

6. RPMs That Fluctuate

Variable RPMs are another sign of a blown head gasket that you could see. Idle RPMs aren’t always an indication of a blown head gasket and can be caused by a variety of factors, but if you notice your idle RPMs fluctuating along with the other, more obvious symptoms, it could indicate a problem.

The idle air control valve would be the most obvious cause, but you should have the car’s computer examined for error codes to pinpoint the issue.

What are the Common Causes of a Blown Head Gasket?

There are several potential causes of head gasket failure. These things might all be issues on their own. It’s crucial to understand the potential causes of the head gasket damage you initially experienced.

1. Incorrect Installation of the Head Gasket

An engine that has had a new head gasket installed can have the same issue once more. When repairing an engine, it’s sometimes impossible to put it back together exactly the way it was originally designed, which frequently leads to lower performance, among other problems.

Rarely, but occasionally, a human mistake can result in incorrect positioning of the metal sheet when installing a head gasket or fastening the engine. A poor installation won’t be able to contain the fluid and might quickly start leaking again.

2. The Thermostat Is Stuck Close

The thermostat is a tiny valve found in the cooling system that controls how much coolant enters the system and how much of it is recirculated into the radiator to release the trapped heat.

The thermostat can produce excessive heat and break or damage the gasket if it is somehow unable to control the flow of coolant or if there is a significant buildup of debris.

3. A Defective Radiator That Has Clogged or Non-Responsive Fans

A poor radiator is another potential factor in the failure of a head gasket. It can harm the head gasket like how inadequate coolant circulation does. The coolant passing over the engine block will become heated without having a chance to cool down properly due to the radiator’s poor efficiency.

In essence, this will put more strain on the engine, which will cause the gasket to stretch and flex. Due to the ineffective cooling of the already hot engine, you can also notice a burning stench coming from the coolant.

Copper flange gaskets by Lanthanum57 / CC BY-SA 3.0

They are used for ultrahigh vacuum (UHV) fittings and come in two distinct sizes. According to the concentric etching at the borders, the gaskets have been used. This helps reduce head gasket blowing off frequently.

4. Contaminated Engine Oil

Most people believe that the only purpose of motor oil is to lubricate the moving parts. In truth, though, it also aids in cooling the engine. Engine oil helps to lower temperature by reducing friction from close motions caused by lubrication.

Another typical reason for an overheated engine is inadequate lubrication. A blown head gasket may eventually occur if the engine is driven for a substantial amount of time with insufficient motor oil or with one that is soiled or polluted.

Therefore, changing your engine oil at the proper intervals will help you not only get greater performance but also avoid repairs that would cost as much as a new automobile.

5. A Misfiring Engine

Misfires in an engine can be quite damaging to its internal workings. Misfires can affect the head gasket as well as perhaps irreparably ruin the engine if left uncontrolled.

It is advised to stop driving right away and get the engine checked for problems if you hear any strange noises coming from the engine or notice any form of shudder or splutter. Misfires can have many different causes, but when they are addressed promptly, they are typically rather simple to solve.

What Is the Procedure for Diagnosing a Blown Head Gasket?

Carbon dioxide testing is a reliable method of determining whether a head gasket is blown. This test looks for signs of combustion fumes in the coolant. The test is conducted using a device that makes use of a solution whose color changes when it comes into contact with carbon monoxide. Following are the steps:

- Reduce the radiator’s coolant level (to provide a testing air space).

- Reheat the engine (for improved accuracy).

- Utilize the gadget to take samples of the fumes from the coolant.

- Mix the test solution with the samples.

The coolant has failed the test and there is an issue if the solution turns yellow. However, the test isn’t always accurate, and carbon dioxide may still be present in the coolant even if the solution doesn’t change color. However, the test is typically accurate in identifying an issue that is a sign of an unhealthy engine.

A cylinder head that has burst, which exhibits symptoms identical to those of a failing head gasket, is another issue that a carbon dioxide test can identify. A cylinder head fracture may frequently be too small to be seen with the naked eye, yet it may still be a serious issue.

In some repair businesses, fractures are discovered by the use of dyes or pressure testing. Cylinder head testing is best carried out by a qualified auto mechanic, just as coolant checks.

Is It Safe to Keep Driving On a Blown Head Gasket?

Although it is not advised, a vehicle may typically be driven with a blown head gasket. The performance of an engine depends on the seal between the cylinder head(s) and engine block. Therefore, a variety of drivability-related problems will eventually result from the breakdown of this seal.

To access it, it is necessary to first remove the intake manifold, fuel lines, hoses, and wiring. You can also see the damaged gasket, cylinders, and engine block once the cylinder heads have been removed.

The majority of the time, a failing head gasket will eventually result in more overheating problems. Several head gasket failures result in coolant loss, either exterior leaking or escape inside a particular cylinder.

The capacity of your cooling system to control engine temperatures will be dramatically reduced over time as a result of this fluid loss.

In some circumstances, a head gasket leak may let coolant and lubricating oil combine in an engine. Dilution of the oil is inevitable when this happens. The crucial bearings in an engine might soon suffer damage from this drop in oil viscosity.

Because of this, a leaky head gasket may eventually call for an engine overhaul.

How Much Does a Blown Head Gasket Repair Cost?

A new head gasket is never inexpensive. The precise cost of these repairs might, however, differ significantly from one car type to the next.

This price variation is due to the cost differences between different head gaskets and the labor-intensive nature of replacing the head gasket(s) on a given engine.

A full head gasket repair typically costs between $1,200 and $2,000 on average. The higher end of this price range corresponds to the majority of high-end “V” configuration engines, while the lower end of the price range is representative of replacement in an inline-style engine.

How Can You Avoid Head Gasket Failure?

The most effective approach to stop head gasket leaks is to closely monitor your car’s cooling system. This entails examining the state of each heater core and coolant hose, as well as routinely monitoring the water pump and thermostat housing seals on your engine for fluid leaks.

If any problems with the integrity of the cooling system are discovered, repairs should be made very away. Delaying such maintenance might result in an overheating problem at any time, which increases the possibility that your engine’s head gasket will fail.

How Long Can a Head Gasket Last With Proper Maintenance?

The normal lifespan of a head gasket is 200,000 miles, which is also the average car’s lifespan. Thus, if you take care of your vehicle and adhere to the recommended maintenance plan, a blown head gasket should never occur.

Can I DIY Fix My Head Gasket?

A head gasket set can cost as little as $45, while some can cost up to $1,300. Although purchasing a head gasket is rather simple, depending on the engine, fixing a damaged head gasket might be challenging.

If you have the necessary tools and are mechanically inclined, you might fix standard inline or V-cylinder engines. However, the top portion of the engine must still be disassembled.

Consult a shop manual for your particular engine before removing any components to access the cylinder heads. Tools and processes are varied for various engines. Observe the directions.

To access the cylinder head, it is necessary to first remove the intake manifold, fuel lines, hoses, and wiring. To avoid damage, be careful, and designate the connections to make reinstallation easier.

You can see the damaged gasket, cylinders, and engine block once the cylinder heads have been removed. First, remove the old gasket with a scraper before installing the new one with a sealant. Inverting the sequence in which they were removed, reassembling the components.

Expect the head gasket repair process to take a day or a weekend to complete if you decide to take on the challenge. Depending on the automobile, there may be a lot of obstructions that must be cleared. Make sure you have a method to bring the engine to repair if you find a crack in the block or cylinder head.

Cylinder head with valves and camshafts by Joe Flores / CC BY-SA 3.0. The pistons and cylinders of your car’s engine are housed in the cylinder block, while the valves, spark plugs, and camshafts are all found in the cylinder head. The head gasket sits in cushioning between these two substantial engine components.

What Is the Difference Between a Blown Head Gasket and a Cracked Head?

Although it happens seldom, a cracked cylinder head in an engine can cause symptoms like those of a blown head gasket. But fixing a damaged head involves much more than just changing the head gasket.

Such problems necessitate either head repair or head replacement since cylinder heads are essential structural elements of any engine. An engine’s head gaskets will also be changed during these repairs.

It might be challenging to distinguish between a fractured head and a blown head gasket. Both combustion fluid and gases may wind up in places they would not normally be because of each problem.

However, once an engine warms up and the fracture itself closes, many problems caused by a broken cylinder head will seem to go away.

If a cylinder head’s integrity is in question, it should be transported to a machine shop so that more testing may be done. Most machine shops routinely “hot tank” questionable heads to visually see cylinder head fractures that could otherwise go undetected.

The Conclusion

The head gasket’s job is to keep the engine block and cylinder heads’ internal fluids from contacting one another. These fluids typically include combustion chamber air/fuel mixture, coolant, and oil.

The term “blown head gasket” refers to a head gasket leak. Engine overheating is the most frequent cause of a burst head gasket.

As a result, it’s critical to constantly check that the coolant level is appropriate.

There are two potential problems with the combo. For instance, coolant and oil both have the potential to seep into the lubricating system. Oil and coolant frequently seep into the combustion chamber.

The most typical symptom is an overheated engine. However, additional signs like engine banging and white exhaust smoke from the exhaust pipe are not unusual.

Repairing a blown head gasket is more expensive than using a head gasket sealer. However, this is seldom a long-term fix, and it frequently doesn’t work at all.

Due to the significant labor expenses required, replacing a head gasket is one of the most expensive auto repairs. The head gasket is sandwiched between the engine block and the cylinder heads, explaining why.

The cost of repairing a head gasket ranges from $1200 to $2000 on average. The labor cost, however, can be 10 times higher, if not higher.

Typically, you may anticipate spending $900 to $1500 on labor expenditures alone.

Additionally, bear in mind that other parts may sustain damage as a result of a burst head gasket. The cost of the repairs might become significantly greater.

Nyangano Maurice specializes in vehicle troubleshooting and has more than 10 years of experience in the automobile industry. Over many years of experience as a car mechanic, he has acquired a broad range of skills, including engine repair, brake systems, electrical systems, and more. He frequently hosts community workshops and training programs to help motor vehicle owners understand their vehicles better.