Even the most experienced drivers might mistake gearbox troubles for torque converter faults. It’s a good idea to take into account the possibility that the problems may be coming from the torque converter before you spend hundreds (and maybe thousands) on gearbox repairs.

The torque converter replacement cost is significantly less than that of a gearbox.

The average price to replace a torque converter is between $600 and $1,200. However, the cost is substantially lower if you believe you can make the repairs yourself.

The amount you will see ranges from $150 to $500. (just for the parts). As you can see, labor charges, which range from $400 to $700, account for the majority of torque converter replacement costs.

You must take your automobile as soon as you can to repair it if the torque converter malfunctions. Unfortunately, it is sometimes more expensive to make significant repairs to this item than to replace it entirely.

The typical cost for automobile owners would be between $600 and $1,200, however, some models may cost more. The price may change based on the amount of labor required.

For instance, the price for a simple torque converter replacement on an Acura MDX might reach $2,350. Here is all the information you want regarding torque converters.

A Torque Converter: What Is It?

The rotational power from a prime mover, such as an engine, to a rotating driven load, is transferred via a torque converter, a form of fluid coupling.

Typically, a pump impeller and a turbine are mounted on a single shaft to form the torque converter. The fluid is directed into the turbine blades by the pump impeller, which pulls it from a sump.

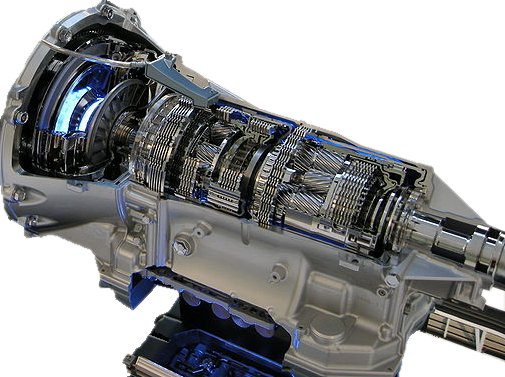

A ZF torque converter cut-away by Aconcagua / CC BY-SA 3.0. It is the torque converter’s responsibility to transfer engine torque to the gearbox. This fluid connection is placed and tightly secured to a “flexplate.” between the transmission and the engine. This “flex plate.” is rotated by the crankshaft.

The shaft to which the turbine blades are mounted drives the turbine itself. The fundamental benefit of using a torque converter over other kinds of fluid couplings is that it can still transfer power even if the input and output shafts are not aligned.

Because the wheels must revolve at a fairly consistent pace but the engine speed can vary greatly, this makes it perfect for use in automobile applications.

A Torque Converter: What Does It Do In a Car?

The torque converter’s job is to transmit engine torque to the gearbox. Between the transmission and the engine, this fluid connection is installed and firmly fastened to a “flexplate.” The crankshaft turns this “flex plate.”

The internal combustion engine produces power as it consumes fuel, which causes the pistons to revolve around the crankshaft. The torque converter distributes the rotational force to the gearbox through fluid pressure.

A pump is a group of propeller-like blades that are housed inside the torque converter. The impeller, another blade assembly, and the engine crankshaft rotate together to propel the transmission fluid onto this assembly.

The transmission input shaft is connected to this second set of blades. As a result, the transmission experiences some hydraulic pressure, and the pressure determines the gear and speed of the vehicle.

The hydrodynamic circuit’s engine component controls the impeller’s speed. The impeller slows down considerably while the pump continues to run when the driver applies the brakes or the vehicle is stopped.

By enabling the engine to continue even while the automobile is entirely still, the torque converter may function as a clutch.

Once the impeller blades have received a good dosage of transmission fluid, the cycle must return to the pump. To prevent the engine from stopping and/or slowing down, the fluid must be reversed because it is now traveling in a different direction.

For this, a third finned wheel known as the stator is positioned between the two turbines on the transmission pump shaft. Its blades are perfectly oriented so that when transmission fluid strikes them, it reverses directions and is sent to the pump.

When the automobile comes to a halt, the built-in one-way clutch compels it to stop spinning, breaking the hydrodynamic circuit.

The Role of the Torque Converter In Kickstarting the Transmission

When the automobile starts to drive from a halt, the stator may spin once again. In a single second, the transmission fluid returns to the stator and kickstarts the transmission pump, temporarily increasing the engine’s torque output. This causes movement by forcing more fluid into the driveshaft by the transmission pump.

The stator’s one-way clutch opens when the vehicle is moving, allowing it to spin in the opposite direction from the other turbines. This completes the hydrodynamic circuit by reversing the flow of fluid.

The lockup clutch is activated, connecting the impeller to the front cover of the torque converter when the vehicle has reached cruising speed and all of the transmission gears have been changed. At this time, a direct overdrive/drive situation is initiated between all of the turbines.

Where Is the Torque Converter Located In a Car?

The torque converter is located between the engine and the automatic transmission. It is necessary to remove the car’s engine and transmission to troubleshoot any potential issues and carry out a visual assessment.

A cut-away model of a torque converter by BerndB~commonswiki / CC BY-SA 3.0. The automatic transmission and the engine are separated by the torque converter. To conduct a visual inspection and resolve any possible problems, the car’s engine and transmission must be taken out.

Some vintage American cars come with a cover plate that may be removed to inspect the torque converter. With the torque converter’s seal in place, though, little can be seen. For an accurate diagnostic, we strongly advise taking the torque converter out of service.

Having said that, if you have never worked on a car before, kindly avoid conducting any “repairs” on your automobile.

The Most Typical Torque Converter Issues

There are a few typical issues that might arise with torque converters. Older cars typically include a torque converter, which is not a highly sophisticated component and has few potential failure points.

It is occasionally possible to locate inexpensive whole replacements for torque converters, in which case it is frequently not necessary to disassemble the converter and replace individual components because doing so is both more expensive and time-consuming.

1. A Defective Torque Converter’s Bearings

The torque converter bearings are often worn, which is an issue. Although it doesn’t cause slippage or other transmission issues, this might result in the transmission making bearing noises.

If the transmission makes bearing noises, examine the transmission fluid to see if you can see any metallic particles there. If you discover metal fragments, the torque converter bearing is probably to blame.

2. Torque Converter Seal Damage

The pressure inside the converter will be lost if the torque converter’s seal fails, which will result in transmission fluid leaking out.

Slippage, overheating, and other unusual symptoms are all caused by low pressure inside the torque converter. When it comes to a broken torque converter, is one of the most frequent issues.

3. A Defective Torque Converter Clutch Plate

A torque converter has several clutches. The converter clutch is probably malfunctioning if the torque converter is stuck in the driving or idle gear and won’t let the gearbox out. Other signs of a bad torque converter clutch include sliding and jerky acceleration.

4. A Defective Torque Converter Clutch Solenoid

One component that frequently breaks down in an automatic gearbox is the torque converter clutch solenoid. The hydraulic transmission’s fluid pressure as it approaches the lock-up clutch is managed by the solenoid valve. Numerous symptoms, including slipping, overheating, and jerky acceleration, may result from this.

What are the Symptoms of a Bad Torque Converter?

The symptoms of torque converter issues are easily mistaken for those of a failing gearbox. People will thus end up having to spend thousands of dollars only to fix or replace their transmission.

They fail to take into account the possibility that the torque converter may be the problem. Compared to the transmission, the torque converter is far less expensive to replace.

If the torque converter malfunctions, the automobile must work more just to keep its speed constant. Higher RPMs will be required by the engine to perform properly, which will reduce fuel efficiency and transmission fluid pressure.

Automatic transmission cut by Silverxxx / CC BY-SA 3.0. Check the transmission fluid for any visible metallic particles if the transmission produces bearing sounds. The torque converter bearing is likely to be at fault if you see metal shavings.

The system’s worse aspect, though, is that it generates extra heat, which might make life much harder for you and your car. Check out this list of typical signs of a malfunctioning torque converter:

1. A Slipping Transmission

A broken bearing or fin might cause the gearbox to slide a gear or delay a change since a torque converter is responsible for generating the hydraulic pressure needed to shift gears inside the driveshaft from engine torque.

Moreover, the amount of fluid in the gearbox may be too much or too little, which might cause slipping. Along with a significant drop in fuel efficiency, you can also experience a lack of acceleration.

Check the fluid levels on your car before taking it in for repairs.

2. Transmission Overheating

If the temperature gauge on your car indicates that it is overheating, there may be a problem with the torque converter and a loss in fluid pressure.

A converter can no longer transfer engine power to the gearbox when it overheats. Inadequate throttle response results from this, along with substantial internal transmission wear and tear.

Transmission overheating can also be brought on by a broken solenoid or low fluid levels.

3. Car Shuddering

Around 30-45 mph, you could sense the car shaking as the lockup clutch in the component under discussion starts to fail. It’s simple to get used to, and it typically seems like you’re driving over a road with many little bumps.

The conversion to direct drive may be complicated by a worn lockup clutch, giving the sensation of trembling. Even though the sensation can not last very long and may come and go rapidly, if you’ve observed it more than once, it’s imperative to get the transmission looked at.

4. Impurities In the Transmission Fluid

In a torque converter, automatic transmission fluid (ATF) is present. The internal components might be harmed if the fluid is contaminated. The stator might therefore have worn bearings or one of the turbines could have fin damage. The state of the ATF should be revealed by routine auto maintenance.

If there is a lot of filth, debris, or sludge in the fluid, the transmission or converter may be damaged.

Replace the drive and fluid in this situation, then check the fluid again. Consult a licensed mechanic if the issue continues or worsens.

5. Stall Speed RPM or Higher Gear Engagement

Stall speed is the speed at which the engine’s RPMs are high enough to send power to the gearbox from the engine. In plainer terms, the stall speed is the RPM at which, in the case that the transmission output is halted, the converter prevents the engine speed from rising.

The engine’s rotational force cannot be adequately converted into hydraulic pressure in the presence of a damaged torque converter. As a result, the stall speed rises as the transmission takes longer to engage the engine.

Automatic transmission fluid (ATF) is found in torque converters. If the fluid is polluted, the internal parts might suffer. It is therefore possible that the stator’s bearings are worn or that one of the turbines has fin damage.

6. Unusual or Strong Sounds

Unusual noises will start coming from a torque converter as it begins to malfunction. You could hear noises like “whirring” from worn-out bearings or “clinking” from damaged turbine fins, among others.

7. Associated Issues

Sometimes the torque converter is not the cause of the issue. You might have transmission issues in your automobile if a solenoid fails.

One common cause for worry is when the vehicle becomes stuck in a low gear (such as second or third) and won’t properly shift in either direction. The shift solenoid could be at fault in this case.

The cost of fixing this should be less than the torque converter replacement cost, however, we advise speaking with a reliable expert first.

Torque Converter Testing Procedure

There is no other way to test a torque converter except disassembling it completely. You can, however, verify the component for symptoms of deterioration. This is the approach that we advise you to use to check for torque converter problems.

Warm up the engine by starting it. You should wait for the transmission oil to reach a temperature of around 40° before starting the engine. Sit back since this may take some time. To make sure the oil has reached the ideal temperature, it is recommended to check the temperature of the transmission oil using a diagnostic scanner.

We proceed to the following stage if the oil is sufficiently heated.

Put the gearshift into motion. Apply the drive and gear, and keep a close ear out for any torque converter sounds. The instant the accelerator pedal is lightly touched, a decent torque converter ought to propel the car forward. If Sport or Drive is the only other gear available, change between them and listen to see if any sounds are coming from there.

Try it out. The torque converter may now be tested by driving the car at high speeds. Watch the tachometer and speedometer closely. If the car dramatically increases its rpm while not accelerating, the torque converter is sliding.

All older gearboxes tend to slide somewhat under acceleration, although owners of well-used automobiles can typically distinguish between normal slippage and artificial slippage. Get a mechanic to test drive your car just in case you’re unsure. They might hear sounds or feel the converter sliding.

Common Causes of Torque Converter Problems

It is beneficial to be aware of the typical problems one could run into with a torque converter before moving on to the topic of torque converter replacement cost.

The majority of older automobiles don’t often have the most cutting-edge parts in this component. In certain cases, it is simple to locate inexpensive full replacements for broken torque converters.

In this instance, we discover that disassembling it and replacing individual components isn’t worthwhile. It would be quicker and more cost-effective to replace the entire thing.

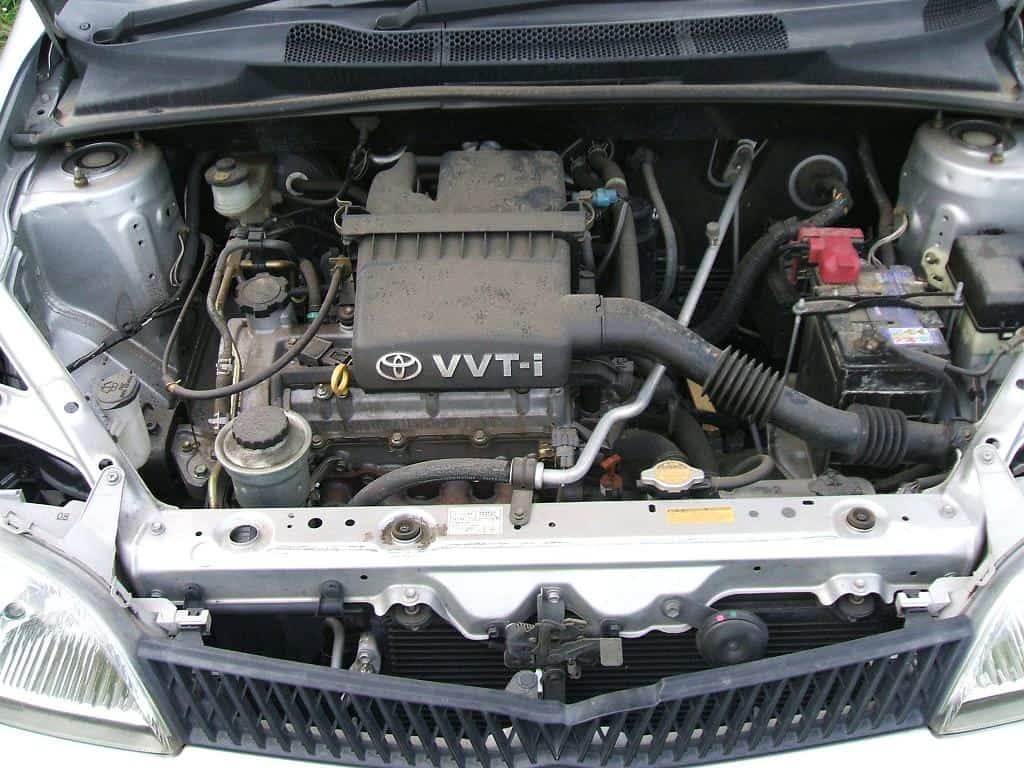

A car engine by Carolla / CC BY-SA 3.0. The engine’s stall speed is the speed at which the engine’s RPMs are sufficient to transfer power to the transmission. Simply explained, the stall speed is the RPM at which the converter stops allowing the engine speed to increase if the transmission output is stopped.

1. Deficient Needle Bearings for Torque Converters

Needle bearings allow the stator, turbine, and impeller to freely revolve. These bearings serve to isolate these revolving components from the converter housing.

As a result of metal-on-metal grinding or contact, drivers will hear weird noises, experience decreased power, and find metal fragments in the ATF if the bearings are broken.

2. Torque Converter Seals That are Damaged

There may be a broken torque converter seal if gearbox fluid is seen dripping from the bell housing. A torque converter won’t have enough strength to efficiently transmit engine power to the transmission if it can’t hold the necessary amount of ATF.

Inaccuracies in gear changing, overheating, faster stall rates, odd sounds, and gear slippage will result from this. As quickly as feasible, the flawed seal has to be found and replaced.

3. Damaged Torque Converter Clutch

Several clutches are dispersed throughout an automated gearbox’s construction. The task of locking the gearbox and engine into direct drive falls to a torque converter clutch.

The procedure will be hampered by a torque converter that has been burned by overheating or locked/jammed because of impurities in the ATF.

As a result, your car can shake and stop locking. An essential component of the clutch plate is the friction material that sits on top of it. This can sustain damage that also compromises a vehicle’s internal mechanisms.

4. A Defective Torque Converter Clutch Solenoid

The torque converter controls how much transmission fluid a lockup clutch of a converter receives.

The lockup clutch won’t work correctly if this electronic component can’t gauge the fluid pressure appropriately since there will be an insufficient or excessive fluid supply. This may result in engine stalling, loss of direct drive functionality, and reduced fuel efficiency.

Which are the Typical Bad Torque Converter Diagnostic Codes?

When an indicator on a driver’s dashboard lights up, it’s obvious how serious an issue may be developing underneath the hood by the look of pure fear on the driver’s face. The anxiety is justified because almost all repairs are expensive.

Typically, the Check Engine Light is a bad indicator. Professionals should be able to identify your vehicle’s issues quickly, but first, they must perform a diagnostic test.

The majority of establishments will provide this service free of charge if you let them handle any repair work (if needed). You would have to spend between $50 and $125 for tests.

If a computer diagnostic can pinpoint the specific problem without requiring several “trial and error” remedies that only lead to frustration, we find that it is cost-effective.

If there is a problem with the torque converter, your car can show some of the following frequent error codes:

P0741

The circuit for the torque converter clutch is broken or stuck “off.” Over 35 mph, gears will start to slide.

P0742

The circuit for the torque converter clutch is locked “on.” When halted, the car will stall.

The car engine bay by Yones / CC BY-SA 3.0. Another benefit of a torque converter is that it may act as a fluid coupling, allowing the engine to idle without stopping the transmission. This is possible because the turbine may continue to rotate even if the input shaft is not.

P0743

The TCC electrical circuit problem. When traveling at high speeds or slowing down, the car could not shift into the highest gear or shake.

P0744

There is improper communication between the TCC and ECU. It might lead to stalling, severe stalling, and being unable to change gears.

P0750

Solenoids in the shift. A malfunctioning shift solenoid might cause the car to shift into the wrong gear, perhaps causing overheating and engine damage.

P2769

Powertrain control module failure, bad wiring, insufficient coolant level, or damaged coolant degassing valve are some possible causes. Additionally, it suggests that the engine might get too hot.

P2770

Check the transmission fluid level and look for any electrical damage.

What Does the Torque Converter Replacement Cost?

Below is a comprehensive breakdown of the torque converter replacement cost:

Torque Converter Replacement Cost: The Cost of Selected Parts

A torque converter or the parts that go with it often don’t cost too much. You may anticipate paying between $150 and $350 for the component, depending on the make and model of your car.

For instance, the torque converter for a Ford Explorer typically costs around $150, but the cost for a Volvo XC90 is nearly 10 times more at $1,300.

The cost of the transmission fluid should also be considered. When working on a component in this manner, it is preferable to refill the fluid and cleanse the transmission system. You will be charged an additional fee for this, or you may do it yourself to save money.

Torque Converter Replacement Cost: The Labor Cost

The majority of the torque converter replacement cost may be attributed to labor costs. It can take anywhere from five to ten hours to completely remove the gearbox from the automobile, replace it, and put it back together.

As a result, labor charges are more expensive than most components — ranging from $400 to $700, depending on your automobile and the shop you take it to. Do you need the fluid in your gearbox replaced and the system flushed? For that, you’ll have to fork up an additional $125 to $250.

Torque Converters: How Long Do They Last?

Torque converters have an expiration date just like every other auto component. Your car may endure from 80,000 to 120,000 miles, depending on how you drive and take care of it.

Of course, you might anticipate needing a new torque converter sooner than someone who drives more cautiously if you frequently pull large weights or race your vehicle.

To guarantee that your torque converter lasts as long as possible, it’s crucial to monitor it and get it repaired as needed.

A check engine light by Wikiuser100000 / CC BY-SA 3.0. In the event of a damaged torque converter, the Check Engine Light is an indicator that is likely to turn on the dashboard. Professionals must first do a diagnostic test before they can determine the problems with the car.

Is Driving a Car with a Broken Torque Converter Safe?

It’s crucial to understand that a converter might progressively degrade over time before failing. It is risky to drive a damaged automobile because it can completely collapse when it turns off, releasing metal shards into the gearbox fluid.

A straightforward converter change might become an expensive transmission replacement or repair if contaminated transmission fluid manages to enter the transmission and cause significant damage.

Are Torque Converters Installed In All Cars?

Torque converters are a common component of automatic gearboxes used in vehicles and light trucks. Torque converters are not employed in all gearboxes, including those seen in big vehicles and construction machinery.

These so-called “direct drive” gearboxes normally employ a fluid coupling to join the engine to the transmission, however, a torque converter would be more effective in this situation.

What Advantages Does A Torque Converter Offer In a Car?

A torque converter’s ability to transmit power even when the input and output shafts are not synced is one of its key advantages. Because the wheels must revolve at a fairly consistent pace but the engine speed can vary greatly, this makes it perfect for use in automobile applications.

A torque converter also has the advantage of serving as a fluid coupling, which enables the engine to idle without stalling the transmission. Due to the turbine’s ability to keep rotating even when the input shaft is not, this is conceivable.

Last but not least, a torque converter can offer a mechanical benefit by multiplying the torque produced by the engine. This may be helpful in situations requiring a lot of torque, such as pulling or lifting big goods.

What are the Constraints of Torque Converters In Cars?

While adopting this kind of fluid connection has certain drawbacks, torque converters offer many benefits. They are often less effective than other forms of fluid couplings, which is one of their primary downsides. As a result, they could make the engine work harder and consume more gasoline.

The fact that torque converters bulk out and add weight to the transmission is another drawback. The gearbox may become less sensitive as a result, and it may also become more prone to overheating.

Last but not least, torque converters need to be repaired and flushed often to avoid damage caused by debris or dirt in the fluid.

The Conclusion

The torque converter replacement cost is significantly lower than those associated with transmission repair or replacement. Any issue with either component would manifest in a multitude of ways, making it difficult to determine which is broken.

For such a replacement, the majority of consumers wouldn’t have to fork up more than $700 and $850. However, customers may wind up paying more or less depending on the type and manufacture of a car.

Before repairing a garage, we advise you to inquire about and acquire many quotes because labor accounts for the majority of the cost. Because dealerships are typically more expensive than your neighborhood car dealerships, you might wish to hire a transmission professional for this type of work.

In case there is a problem, later on, it’s a good idea to find out what kind of guarantee is offered on the parts and workmanship. The cheapest quote isn’t always the greatest when you take into account the garage’s reputation and warranty.

Keep in mind that scheduling routine maintenance is the best way to prevent having to spend a lot of money on replacing or repairing items like transmissions or torque converters.

A ZF torque converter cut-away by Aconcagua / CC BY-SA 3.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”