What are the best indicators that your car needs repair? After starting the automobile, there is a bad odor, the engine sputters, and there is an interior groaning sound.

One of them can indicate that you need to take your car to the technician. You may keep an eye out for the check engine light as well.

The alternative name for a check engine light is the Malfunction Indicator Light or MIL. When a car has a problem, this light will flash. Is P0335 displayed in your DTC?

You can identify the problem thanks to the flashing light. By looking for the DTC, you might learn more about the problem itself.

A diagnostic trouble code, often known as a DTC, is used to pinpoint any problems with heavy machinery or vehicles. The engine check light informs the driver that the car has a problem.

The DTC code is used to specify the nature of the problem and its source. A crankshaft position sensor A problem is often indicated by the DTC code P0335.

The code may be displayed for still another purpose. Yet, as this is the most frequent scenario, let’s learn more about this problem and how to identify it.

What Does Code P0335 Mean?

The Diagnostic Trouble Code (DTC) P0335 indicates a problem with the crankshaft position sensor A. This error number denotes a failure of the vehicle’s electronic control module to recognize the crankshaft position sensor.

Being a generic powertrain code, it applies to all vehicles with OBD-II technology (onboard diagnostics). The repair procedures may vary depending on the brand or model of the vehicle, even though they are generic.

The software of the car is typically informed of the engine speed through the crankshaft position sensor or CKP sensor. The ECM, or engine control module, uses this data to decide when to inject fuel and when to ignite the air-fuel mixture.

The check engine light by Wikiuser100000 / CC BY-SA 3.0. A check engine light on the dashboard is the most evident sign that the crankshaft position sensor is damaged. Another possibility is a stalled engine or poor engine performance.

A reluctor ring affixed to the crankshaft works in conjunction with the CKP sensor. It provides the ECM with current information regarding the crankshaft’s location.

A square wave voltage indication is created when the ring moves in front of the sensor, which the ECM interprets as the crankshaft position. Trouble code P0335 is set off when the ECM fails to detect crankshaft pulses or detects a problem with the pulses coming from Sensor “A.”

What are the Typical Signs of the P0335 DTC Code?

In addition to the DTC code flashing in your check light, you may notice other odd behaviors in your car that indicate the presence of a P0335 code.

Some vehicles won’t even turn on, while others run poorly and exhibit a loss of engine power and torque. A strong idle and stuttered driving may be experienced by some drivers.

Even though this is not a general rule, the primary source of the problem usually determines the indications.

If your crankshaft position sensor is broken, the ECM won’t be able to make these alterations, which will result in slow acceleration.

Poor spark timing is another effect of a malfunctioning crankshaft position sensor, which can lead to several problems, most notably the misfiring of one or more engine cylinders. This will be perceived or audible as a small engine glitch.

The MIL may flash if only used to indicate misfires. But before the MIL illuminates, the car must pass through several steps.

However, the car might not start if your vehicle uses the crank sensor to check for misfires and improper spark timing. As a result, a misfire, MIL lighting, or a reluctance to start are the most typical P0335 code symptoms.

What are the Main Causes of Code P0335?

Your top objective after finding the P0335 code is to identify the vehicle’s problem. Crankshaft position sensor A damage is frequently the cause of code P0335.

Your car may flash this code for numerous reasons, but the most likely one is a broken crankshaft position sensor. Some frequent reasons for the P0335 DTC code include:

- Crankshaft position sensor which is broken

- insufficient electrical connections

- Connectors on the wiring harness are improperly attached.

- Defective signal plate

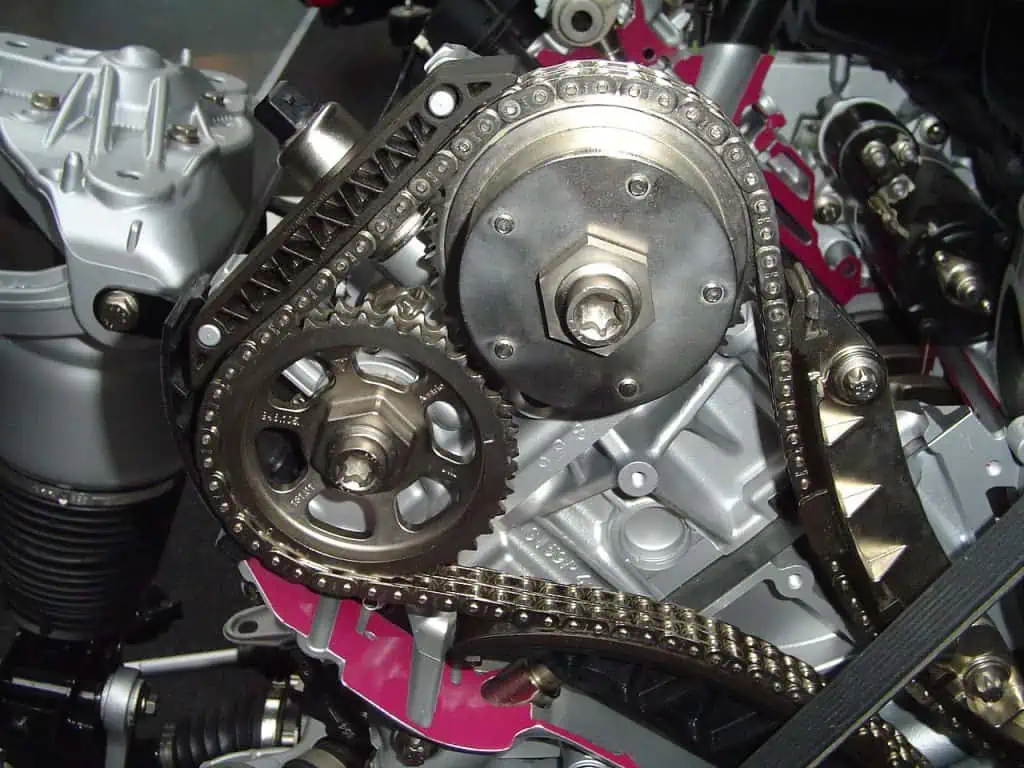

- Timing belt or chain failure

- Crankshaft sensor wiring problems

- Damaged reluctor rings

- A malfunctioning engine control unit

A typical inductive crankshaft position sensor by Tamasflex / CC BY-SA 3.0. The DTC code is used to specify the nature of the problem and its source. A crankshaft position sensor A problem is often indicated by the DTC code P0335.

What Is the Crankshaft Position Sensor’s Working Model?

The crankshaft position sensor keeps track of the precise location and rotational speed (RPMs). In the absence of a crankshaft position sensor, the engine will not start.

Hall Effect sensors, a type of electrical sensor, are used in many crankshaft position sensors. A Hall Effect sensor produces electricity when exposed to a magnetic field.

The magnetic field of a crankshaft position sensor is disrupted by a toothed wheel that rotates along with the crankshaft.

As a result, the Hall Sensor experiences a series of on and off switches, which the ECU (Engine Control Unit) interprets as crankshaft speed. The sensor’s on/off cycle speed determines how quickly the crankshaft spins.

Typically, a metal disk or ring with a certain hole pattern is mounted on the base of the crankshaft and acts as the component that disturbs the magnetic field.

While the crankshaft spins, the hole pattern is seen in the data from the crankshaft sensor. The number of holes in the disk and the crankshaft’s rotational speed affects the frequency of the signal.

The ignition system of the engine is regulated and controlled by the powerful computer known as the PCM (powertrain control module). Also, it may keep an eye on the alignment of the exhaust system, rotating unit, gearbox, and emission components.

The anti-lock brake system can even be controlled by this, along with other actively connected functions to the engine and gearbox. Crankshaft position sensor data is used to determine when and which cylinders should ignite.

Crankshaft position information is also used to detect misfires in any cylinders. The fuel injectors won’t function if the sensor signal is absent since there might not be a spark.

The Crankshaft Position Sensor: Where Is It Found In a Car?

Every car has a different location for the crankshaft position sensor. It normally resides on the front bottom of the engine, which ought to be close to the crankshaft. It frequently finds itself fastened to the timing cover.

It may occasionally be placed near the side or back of the engine. The crankshaft position sensor frequently measures the clutch flywheel’s speed to regulate the crankshaft’s speed. The sensor may occasionally be fastened to the bell housing of the transmission.

What are the Warning Signs of a Failing Crankshaft Position Sensor?

A check engine light on the dashboard is the most obvious indication that the crankshaft position sensor is broken. A stalled engine or subpar engine performance could also be apparent. In strange circumstances, you could also encounter engine tremors or misfires.

Although these are the most prominent symptoms, a broken crankshaft position sensor can be caused by other signs as well. We’ll take a closer look at some of the most prevalent symptoms of a bad crankshaft position sensor below to help you evaluate the vehicle.

The Engine Control Module (ECM) by Mgiardina09 / CC BY-SA 3.0. The CKP sensor cooperates with a reluctor ring attached to the crankshaft. It gives the ECM up-to-date data about where the crankshaft is.

1. A Check Engine Light Illuminates

Several circumstances can cause the check engine light to blink. Crankshaft position sensor malfunction is one of these reasons.

The check engine light on your car’s dashboard will start to flash right away if the engine management unit does not receive a proper signal from the sensor and decides that something is wrong.

You can see P0335-related codes for the crankshaft position sensor when using an OBD2 scanner to check for error codes.

2. Difficulties Starting the Vehicle

Starting issues are the most apparent symptom of a failing or damaged crankshaft position sensor. Regardless of the brand or model of the car you drive, engine difficulties are prevalent. The crankshaft sensor is crucial to keeping the engine running smoothly.

The crankshaft position sensor measures the crankshaft’s position, speed, and other crucial data when starting an engine. The automobile may start infrequently or not at all if the crankshaft position sensor malfunctions.

3. Stalling of Engine

The engine control module as well as the crankshaft are connected by several wires that make up the crankshaft position sensor.

The engine control unit won’t be able to receive the sensor’s data signal if any of these cables are damaged or burned out.

Your engine will likely stall if you continue to drive with a frayed wire or other damage. It can occasionally stall regularly and occasionally stall at odd places.

Stalled car engines may be rather unpleasant, especially if you need to get someplace soon. The sensor should be checked to make sure it is in good working order.

4. A Lower Gas Mileage

If timing information is not provided, fuel injection will not function as efficiently as it should. The engine will thus use more fuel than usual.

Your pocketbook would get lighter as a result of the need for more frequent gasoline refills. As there are many potential causes of poor fuel efficiency, have a professional inspect the sensor.

5. Unusual Acceleration

Due to inaccurate data from the crankshaft position sensor, the engine control unit is unable to adjust spark timing and fuel injection when the engine speed increases. Lack of precision can result in slow or erratic acceleration, which makes it challenging to keep up a steady pace.

6. Misfire In the Engine

An extreme increase in engine vibration could be the result of a cylinder misfire. A crankshaft position sensor that isn’t working may be the root of this issue. You might be getting false information from the sensor about where the pistons are.

Get the spark plugs checked out as well because they may be the source of this issue as well. When the crank position sensor is at fault, the spark plugs are almost always the problem.

A typical onboard diagnostics (OBD) handheld scanner by Arp. The crankshaft is an essential component of an engine. Although the OBD-II scanner error code P0335 problem involves the crankshaft, the code is more concentrated on the electrical parts and modules than it is on the actual crank.

7. Deficient Engine Performance

If your crankshaft position sensor is broken, your car’s engine control unit won’t know where the cylinders and crankshaft should be. This may cause the control unit’s ability to maintain the engine’s performance to lag.

During this waiting period, you might feel a little moment of hesitation every time you press the throttle pedal a little harder. Sometimes it won’t respond at all. On a route where you need to drive fast and without delay, this could be very risky.

How Can You Carry Out Crankshaft Position Sensor Testing?

Misfiring engines, stalling engines, and trouble starting are all symptoms of a broken crankshaft position sensor. If you experience any of these problems, you may need to get a new crankshaft position sensor.

Yet, any of these concerns may be brought on by other conditions. So, you may need to conduct several tests before attempting to diagnose a crankshaft position sensor that isn’t working properly.

Using a CKP (crankshaft position sensor), you can measure the voltage output and compare the results to the specifications set out by the manufacturer. If your voltmeter has needle probes, use them to back probe the wires at the sensor connection.

If doing so is impractical, unplug the sensor’s electrical connector and connect the two pieces using a test connector. Next, reattach the wire.

As soon as the engine is revved, set the digital multimeter to the AC millivolt range. The output voltage of a typical sensor will be higher than 200 mV. But, you should contrast the results with the guidelines provided in your car’s user handbook.

A Crankshaft Position Sensor Replacement

The DTC code can be obtained with a code reader if the vehicle computer has already turned on the engine light. The majority of auto shops or mechanics will recover DTC for the automobile for free if you don’t have a code reader. You can move further with the diagnosis after receiving the DTC P0335.

When replacing or repairing a crankshaft position sensor, a professional may demand a high price. Depending on the manufacturer and model of your car, the real cost of both materials and labor may vary greatly. Also, it may differ based on the shop you take the car to.

The price of the crank sensor and the labor needed to replace it will vary, and certain crank sensors can only be replaced at the dealership because they need particular tools to be programmed.

How Much Does It Cost to Replace the Crankshaft Position Sensor?

Your car’s crankshaft position sensor replacement cost will depend on the sensor’s brand, design, and location.

Some sensors might be hidden beneath the starter or in a challenging-to-reach place, such as the top of the transmission bell box, while some are apparent.

Crankshaft position sensors can be replaced at an average cost of between $120 and $300. If your car is more expensive or has been heavily modified, the cost may rise dramatically.

A typical car engine by Carolla / CC BY-SA 3.0. A cylinder misfire may cause a dramatic escalation in engine vibration. A malfunctioning crankshaft position sensor could be the cause of this problem. The sensor’s readings about the location of the pistons may be inaccurate.

Start working on it right immediately if you have the necessary training and tools to repair a crankshaft position sensor.

The person doing the work has a significant impact on the final cost of a crankshaft sensor replacement service, in addition to the make and model of your car.

Your best bet is to research a few nearby auto repair businesses and request replacement pricing estimates. Even while your local dealership will be happy to fix something straightforward like a crankshaft sensor, you should be ready to pay more.

If you take your automobile to a fancy shop, the labor charge may be more than the actual cost of the replacement crankshaft sensor.

Is Driving with a Failing Crankshaft Position Sensor Safe?

Whenever the crankshaft fails, the answer to the question of whether it is safe to start the car is probably yes. But only when the problem is just acting up can you do that.

It is best to avoid driving the car if the problem has been there for a while until a specialist has examined it. Given that you are familiar with the fundamentals of your vehicle, you should at least perform some early diagnosis on your own.

The check engine light will probably start flashing once the ignition is turned on. The first symptom to watch out for is that. It is safe to assume that your car has a defective crankshaft position sensor if you repeatedly experience any of the symptoms listed above.

After a few engine misfires or erratic acceleration, it is safe to go behind the wheel. Yet continuing to drive that car on the highway is still a little unsafe.

You might experience uneven acceleration in the middle of the road, which could cause you to suddenly lose control of the vehicle. Driving on a congested or busy highway can be extremely unsafe.

Also, driving your car further while in that condition can seriously harm the engine. Your engine may require expensive repairs or, as a last option, replacement.

What are the Alternative Possible Causes of a P0335 Code?

Let’s now examine some of the potential causes of the P0335 error code that you might encounter.

1. Timing Belt Problems

Moreover, signs like an engine misfiring might be brought on by a broken timing belt. This issue with your car may also result in the flashing of error code P0335.

2. Damage to the Timing Chains

P0335 is a code that can be caused by timing chain damage. The engine’s timing can become out of whack as a result of the timing chain stretching over time and skipping a crankshaft gear. Engine misfiring or uneven acceleration is possible.

3. Circuit Issues

A P0335 error code can be brought on by any issue with the wiring or the circuit(s).

4. A Damaged Ring Reluctor

The PCM needs a reference point for the crankshaft position, which the reluctor ring provides. It has a variety of teeth. The P0335 code can be used if the ring has any kind of damage.

An engine’s timing chain by Kolossos / CC BY-SA 3.0. Timing chain degradation can result in the code P0335. The timing chain expanding over time and skipping a crankshaft gear might cause the engine’s timing to become thrown off. The engine can misfire or accelerate unevenly.

A P0335 Code: How Serious Is It?

A major mechanical or electrical fault is indicated by the P0335 error code. Avoid driving the automobile if it won’t start or if there are any issues with the engine’s performance until you can take it to a repair. Several consumers claim that after starting their automobile once, it could stutter and then refuse to start again.

Moreover, the engine may run poorly for a while before failing to restart. Use the troubleshooting procedures to identify the root of the issue, or take the vehicle to a shop to make sure there isn’t a technical issue that could seriously damage the engine and gearbox.

Do not disregard a P0335 error code once you have found it. Getting your car diagnosed as soon as you can is preferable. If the damage is too extensive, it can cost a fortune to repair it at the shop and get your car back to accelerating normally.

How Is the P0335 Code Diagnosed?

To examine for any codes, a specialist will first scan the PCM with a scan tool. Codes from the present, the past, or the future may be found; each one must be reviewed along with the freeze frame information.

Following the clearing of the codes, a road test will be conducted to try to duplicate the symptoms. The crankshaft position sensor and its wiring would then be visually inspected after that.

If there is no evident damage, your mechanic will check the CKP 5 Volt square wave pattern.

You must have access to the scope. If not, see the maintenance guide and get a crank sensor resistance measurement.

It is not possible to provide all of the appropriate resistance data for each crankshaft in one section due to the large variety of different types of crankshaft sensors.

A crucial part of an engine is the crankshaft. Although the crankshaft is involved in the OBD-II scanner error code P0335 problem, the code is more focused on the electrical components and modules than it is on the crank itself.

This makes utilizing a scan tool to visually inspect the parts a wise move. But, if the issue is not apparent right away, get in touch with a knowledgeable specialist who possesses a scoping instrument.

Code P0335: How Can It Be Fixed?

To determine the root of a crankshaft sensor malfunction, the first step is to have it diagnosed.

If your car has this problem and you’re not confident diagnosing it yourself, we advise locating a RepairPal Accredited shop nearby to identify the issue and provide a precise repair estimate.

These shops can not only identify the issue before you waste time and money on the incorrect parts, but they can also guarantee fair pricing on all of their estimates and provide a warranty that lasts at least 12 months and 12,000 miles.

How Much Does the Code P0335 Repair Cost?

Anything from a malfunctioning sensor to an unreliable ECM to a broken timing belt or chain can result in P0335. Without fully assessing the problem first, it is hard to provide a precise estimate.

Most shops will begin with an hour of “diag time” if you bring your car in for a diagnosis (the time spent in labor diagnosing your specific issue). This normally costs between $75 and $150, depending on the labor rate at the shop.

If you hire the shop to handle the repairs, many, if not most, will deduct this diagnosis price from any necessary work. A shop will then be able to provide you with an accurate estimate for repairs to resolve your P0335 error.

An engine’s timing belt by Petar Milošević / CC BY-SA 3.0. A broken timing belt may be the cause of symptoms like an engine misfire. The error number P0335 may also flash as a result of this problem with your car.

Costs of Code P0335 Possible Repairs

The underlying problem for error number P0335 can require one or more of the fixes listed below. The estimated cost of repair includes both the cost of the necessary parts and the cost of the labor needed to complete the repair for each potential repair.

- $168 to $224 for a crankshaft position sensor.

- $272 to $356 for a timing belt

- $1,624 to $1,879 for a timing chain

- $993 to $1,012 for the ECM

What are the DIY Diagnostic Steps for Code P0335?

There are several potential causes for engine code P0335, including a defective sensor, an issue with the ECM, or a damaged timing belt or chain.

You should adhere to the methods listed below for an accurate diagnosis if you want to attempt to fix code P0335 at home without spending money on parts. Remember that this is an intermediate-level diagnosis and repair, so beginners should avoid attempting it.

For novice DIYers, diagnosis can be a time- and labor-intensive process that calls for more sophisticated tools.

Step 1: Verify Engine Speed Information

Look at the engine RPM information. Typically, the crankshaft position sensor is where this comes from. If this data is inconsistent or off, there may be an issue with the sensor or the wire that connects it.

Step 2: Verify the Sensor Wiring

Visually inspect the crank sensor, and connectors, and look for any evidence of fraying or wiring damage.

Step 3: Verify the CKP 5-Volt Square Wave Pattern

The CKP 5 Volt square wave pattern can be examined if no obvious damage is discovered. Which resistance reading is adequate must be determined by consulting the maintenance manual for your car.

The vehicle’s ECM will provide this reading. It is better to leave this stage to a professional if you are unfamiliar with cars.

There is no need to replace the crankshaft position sensor if the reading is within the vehicle’s specs.

However, the crankshaft position sensor needs to be replaced if the reading does not match the vehicle’s requirements. Any frayed or broken wiring must be replaced. If the reading now falls within the acceptable range, there might be a wiring short.

If these techniques fail to identify your problem, it might be in your ECM. You must take it to a mechanic for a more thorough analysis.

What are the Common Errors In P0335 Code Diagnosis?

Even with experience, mistakes can be made when diagnosing any code if the diagnostic procedures are not carried out in the correct sequence.

The crankshaft position sensor is the P0335’s most frequent cause, however, each component must still be examined to make sure that items like a faulty timing belt or sensor ring are not missed.

The Conclusion

This is an easy fix you may perform on your own if you are fixing the wire or sensor. Any solutions that go beyond that will take a lot of time and require specialized timing system component repair knowledge.

If you see a P0335 DTC code, you can start the diagnostic process for your vehicle. So as soon as you can, get in touch with a mechanic. Engine damage could happen if the immediate error code is ignored.

The crankshaft position sensor measures the crankshaft’s rotational speed. This is read by the computer in RPMs. Crankshaft and camshaft position sensors are used by the PCM to alter timing and fuel mapping.

An essential diagnostic tool for P0335 is an advanced-level scan tool. The operation of the crankshaft position sensor will be observed using the scan tool. Also, the scan tool gives professionals access to data on the engine RPM and camshaft position to help them identify the defect.

The check engine light by Wikiuser100000 / CC BY-SA 3.0

Jim Wicks is the founder of MotorVehicleHQ. With over two decades of experience in the automotive industry and a degree in Automotive Technology, Jim is a certified car expert who has worked in various roles ranging from a mechanic, car dealership manager, to a racing car driver. He has owned more than 20 cars over the past 15 years. Ask him about any vehicle you see on the road and he can tell you the make, model and year. He loves the aesthetics of all things cars, and keeps his vehicles in pristine condition.

In his free time, Jim enjoys getting his hands dirty under the hood of a classic car or taking long drives along the country roads. His favorite car? A 1967 Shelby GT500, a true classic that, according to Jim, “represents the pure essence of American muscle.”